Resources

×

![Screenshot of aP Design]()

Drive profitable transformation across product development and your supply chain

A unique data-driven software platform to…What Makes Us Faster & Drives Transformation?

From 3D CAD to Intelligence:

Cost, DFM and more

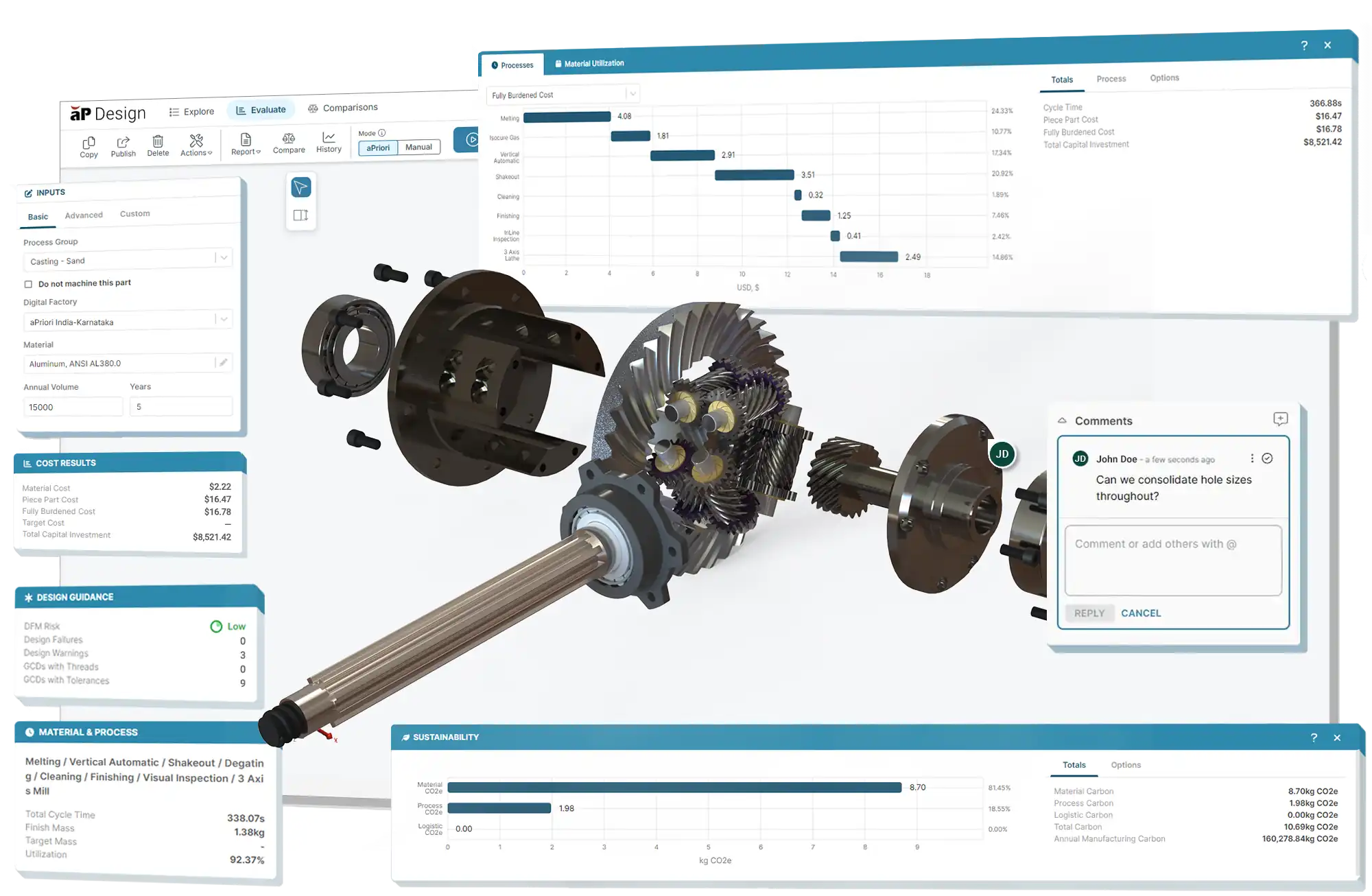

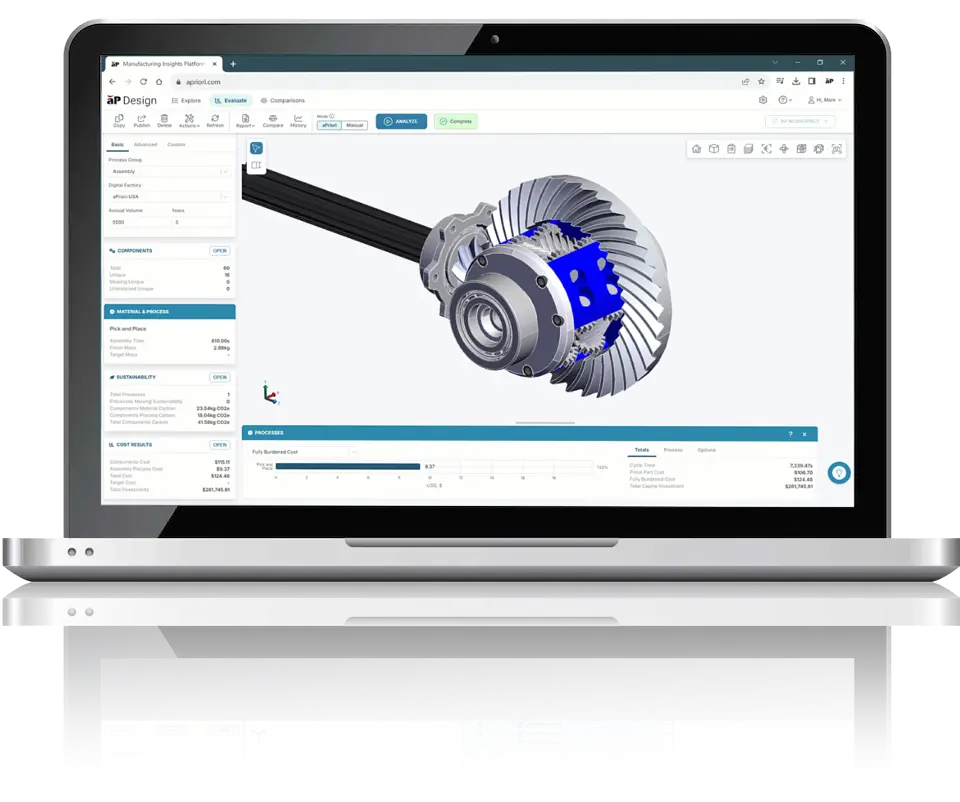

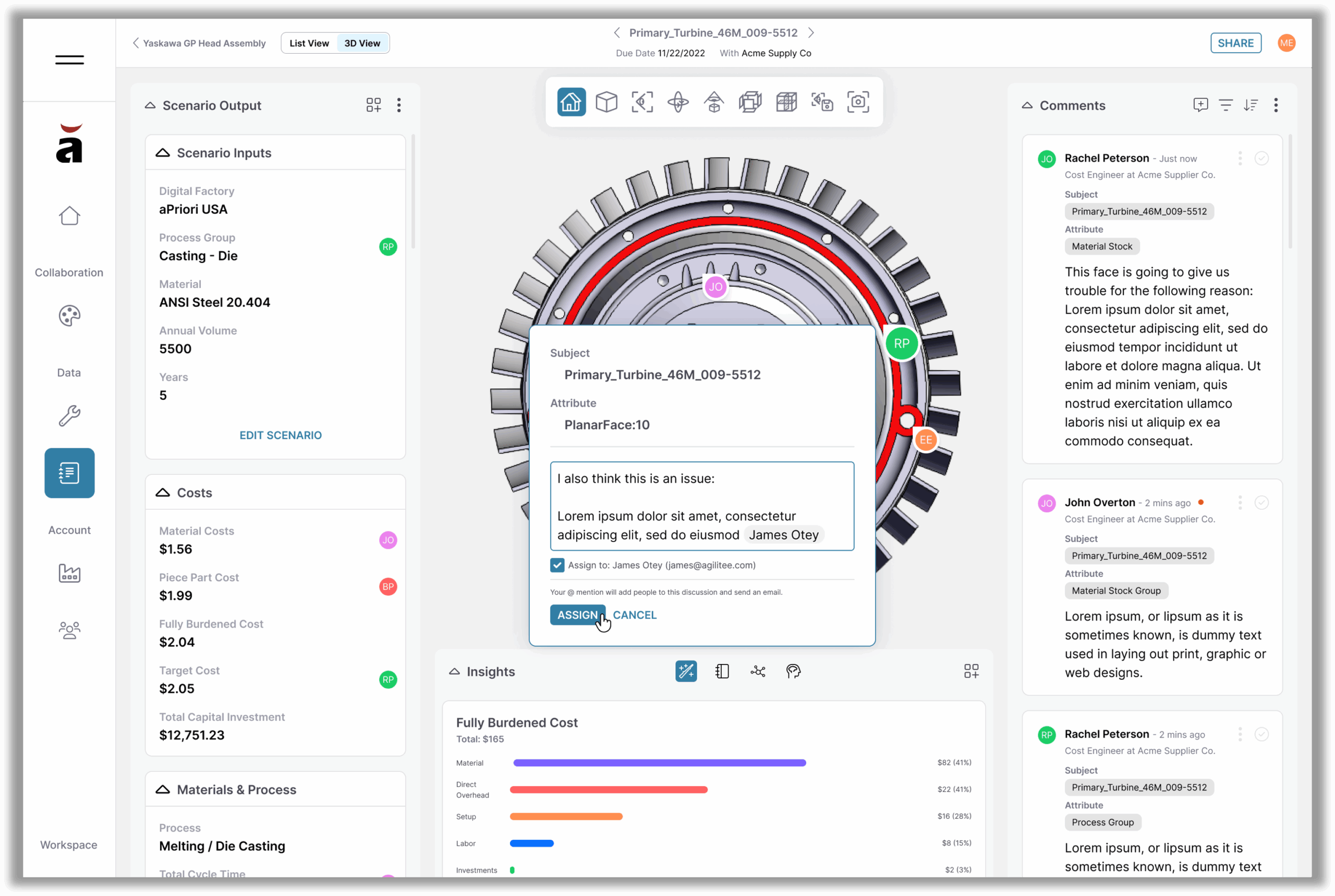

aPriori is helping design engineering, procurement, and manufacturing engineering teams around the globe create the products of the future. Get actionable intelligence to improve cost and manufacturability at every stage of your product lifecycle. Simply upload your 3D-CAD files into aPriori and our digital factories will run a detailed simulation of the manufacturing process in a fraction of the time it takes with manual calculation methods. Stop waiting for suppliers or internal manufacturing teams to provide the data you need to move ahead - reduce the lengthy review and loops cycles today with aPrioriLearn More

Be Ready to Challenge the Status Quo

Design Engineers to quickly review design changes cost & DFM impact

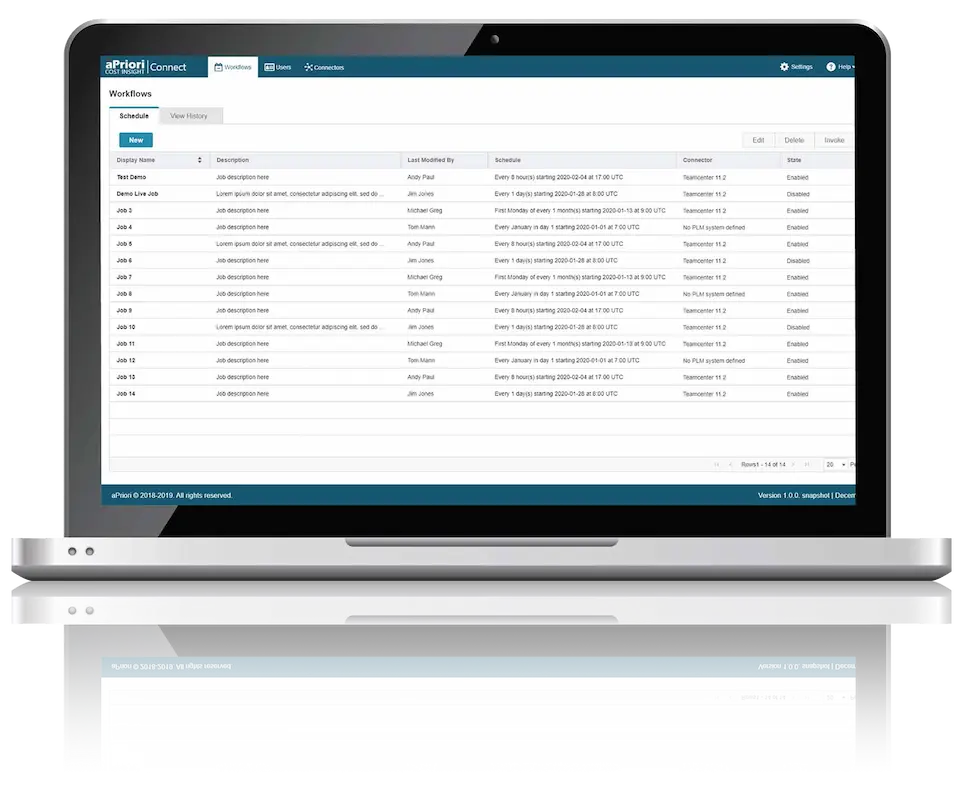

Category Managers & Buyers to create should costs faster to negotiate better with suppliers

Cost/Value Engineers to find new and actionable cost reduction ideas quickly

Estimators to respond to RFQs faster and increase confidence in quoted costs

MFG Engineers to reduce cycle time and find new manufacturing processes

Unlock the Value in Your Digital Twins for Profitable & Sustainable Products

MANUFACTURABILITY

Identify and eliminate manufacturability issues before they reach the sourcing, supply chain, or manufacturing teams.

Learn More