Case Study

How TE Connectivity’s Supplier Relationship Management Drives Savings

Managing the manufacturing supply chain in the face of inflationary pressures and global disruptions poses a significant challenge for manufacturers. To overcome these obstacles, companies like TE Connectivity need to collaborate effectively with all stakeholders and harness the power of actionable, real-time manufacturing data.

This approach is crucial for successful supply chain management, cost mitigation, and making informed procurement and sourcing decisions for a competitive advantage.

In this case study, discover how TE Connectivity uses aPriori’s data-driven cost analysis to improve bottom-line outcomes and drive innovation through efficient supplier relationship management (SRM).

Company Details

Industry

Consumer Electronics

Number of Employees

90,000

Revenue

$16.03 billion

aPriori Product

aP Pro

The Problem

Assessing and reducing critical product costs due to ongoing market volatility and increased supplier expensesThe Solution

Enable proactive supplier relationship management (SRM) and unlock significant cost savings with data-driven expense analysisWho is TE Connectivity?

TE Connectivity is a Switzerland-based global design and manufacturing company that has secured industrial technology leadership in 140 countries. The company produces more than 236 billion products annually for the communications, industrial, and transportation sectors. Its diverse product portfolio includes connectors, sensors, and more, and it comprises renowned brands such as AMP, Buchanan, and DEUTSCH.

To meet the high demand across these sectors, TE Connectivity leverages its network of 106 global manufacturing sites and a robust supplier base. The company’s success can also be attributed to its Center of Excellence (CoE) model, which focuses on applying specialized expertise to address core business issues.

Problem: Assessing and Minimizing Increased Supplier Costs in Uncertain Times

TE Connectivity has various CoE units, one of which is dedicated to the Procurement Cost Analytics (PCA) team. Sylwia Lambert leads the PCA CoE, which is a group of cost engineers committed to two primary objectives. As Lambert explained:

Like other manufacturers, TE Connectivity’s PCA CoE team faces challenges in assessing and mitigating critical product costs with key suppliers. Three inflationary cost issues experienced by the team with its supplier partnerships include:

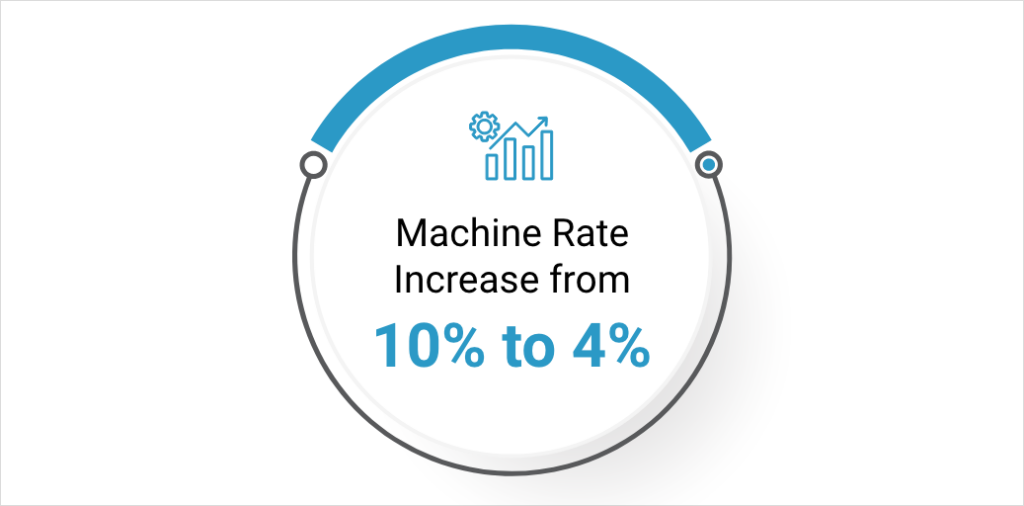

- Rising energy costs of up to 300%, which led to a 10% increase in the supplier’s machine rate. A supplier has recently increased its energy costs by more than 300% and requested a 10% price increase to manufacture a specific product for TE Connectivity.

- A 30% increase in production costs over the past three years. A TE Connectivity supplier has raised its production costs by 30% in the past three years due to the high expenses associated with its complex manufacturing processes.

- Labor and manufacturing quotes in a supplier’s country of operation are 2X the regional average. TE Connectivity requested full disclosure of costs during a supplier evaluation process. The manufacturer received an expensive quote from a Mexican supplier for its 110-ton machine’s labor and machine hourly rate.

Download and view the inflationary costs infographic for a visualization of the challenges.

To evaluate higher quotes against fixed and variable costs impacted by inflation, the procurement team requires transparency from suppliers. This transparency includes insights into factors such as manufacturing overhead, direct labor, and direct material expenses.

With these requirements in mind, the team turned to aPriori’s automated and precise should cost modeling solution to streamline expense-reduction initiatives and increase profitability. Check out the video below to learn more about how TE Connectivity uses aPriori to enhance its supplier relationship management (SRM) process:

Solution: Optimizing Cost Savings With aPriori’s Automation-Driven Expense Analysis

The PCA CoE employs aPriori’s advanced costing capabilities to strengthen its strategic supplier relationships, leading to improved cost efficiency, competitiveness, and vendor management. By leveraging aPriori, TE Connectivity can anticipate cost drivers and generate precise “should costs” for a deeper understanding of a supplier’s overall cost structure.

This accurate forecasting allows the procurement team to engage in fact-based negotiations with suppliers, ultimately reducing costs without sacrificing product quality. Further, aPriori provides the team with a holistic view of supplier performance and capabilities, enabling them to identify suitable providers and succeed in supply chain risk management.

With the power of aPriori, Lambert’s team can address and mitigate the three inflationary cost issues they face in their supplier strategy. The real-world results TE Connectivity achieved when using aPriori to manage supplier price hikes are as follows:

Results: Achieving Double-Digit Cost Reductions Through Informed Supplier Collaboration

1. Do Rising Energy Costs Justify a 14% Supplier Increase?

TE Connectivity employed aPriori to determine the machine overhead rate’s contribution to factory overhead and total product cost, which led to a 10% increase. To assess the reasonability of the requested increase, the PCA CoE team needed to investigate the supplier’s new energy expenses.

With these findings, the team conducted fact-based negotiations with the supplier regarding the overall piece price of 4%. They compared existing and new cost models while considering regional energy expenses. Additionally, the team used scenario comparisons in aPriori to gain a data-driven understanding of how these costs truly impact the unit cost of a specific product or finished good.

Result: The 10% machine rate increase was deemed unreasonable by the PCA CoE team. They realized that only 4% of the machine rate impacted the product.

2. Does a Complex Manufacturing Process Warrant a 30% Increase?

A TE Connectivity supplier has increased its production costs by 30% over the past three years, citing expensive and complex manufacturing processes.

To evaluate this increase, the PCA CoE team assessed their overall product costs. They discovered that raw materials, particularly copper, constitute nearly 65% of the product cost. The procurement team also found that copper prices have dropped 15% in the market.

To optimize cost control with greater precision, TE Connectivity uses aPriori to compare the real-time cost implications of alternative designs and production. aPriori estimates are highly precise and based on real-world variables such as raw materials, direct labor, manufacturing overhead costs, and more.

Result: The PCA CoE negotiated with the supplier and reduced raw material costs by 15%, thus leveling out the increase.

3. Why are Labor and Manufacturing Quotes 2X the Regional Average?

TE Connectivity evaluated potential suppliers and requested full cost disclosures. During the assessment, a supplier based in Mexico provided a quote for labor and machine rates for its 110-ton machine.

To determine the most cost-effective solution, the PCA CoE utilized aPriori’s digital factories. They conducted cost assessments and scenarios specific to various countries using the platform’s Regional Data Libraries (RDLs). The results showed that the supplier’s quoted direct labor cost was nearly double the country’s average. Moreover, the supplier’s quoted machine hourly rate significantly exceeded aPriori’s estimated rate in Mexico and the U.S.

Result: With this background, TE Connectivity gained a stronger position to negotiate with the supplier and reduce the costs associated with labor and manufacturing.

What’s Next?

TE Connectivity is committed to enhancing its SRM process and building mutually beneficial relationships with suppliers to achieve its sustainability goals. As part of this initiative, the company will continue to employ aPriori to reduce cradle-to-gate greenhouse gas (GHG) emissions in the supply chain (Scope 3). This is achieved by monitoring the direct impact of process optimization on key sustainability metrics, such as carbon dioxide equivalent (CO2e) emissions.

One way that aPriori has helped TE Connectivity achieve its sustainability goals is by streamlining the resin production process. Initially, this process included scrap parts, production issues, and other factors that contributed to total waste. However, aPriori has helped identify the waste and material reduction impact that regrind activities can provide as part of the overall resin stream mapping process.

Watch the video below to learn more about TE Connectivity’s sustainability business objectives:

Experience aPriori in Action

Meet with an aPriori expert and learn how we can help you to eliminate product costs, improve productivity, and reduce your carbon footprint.