aP Generate

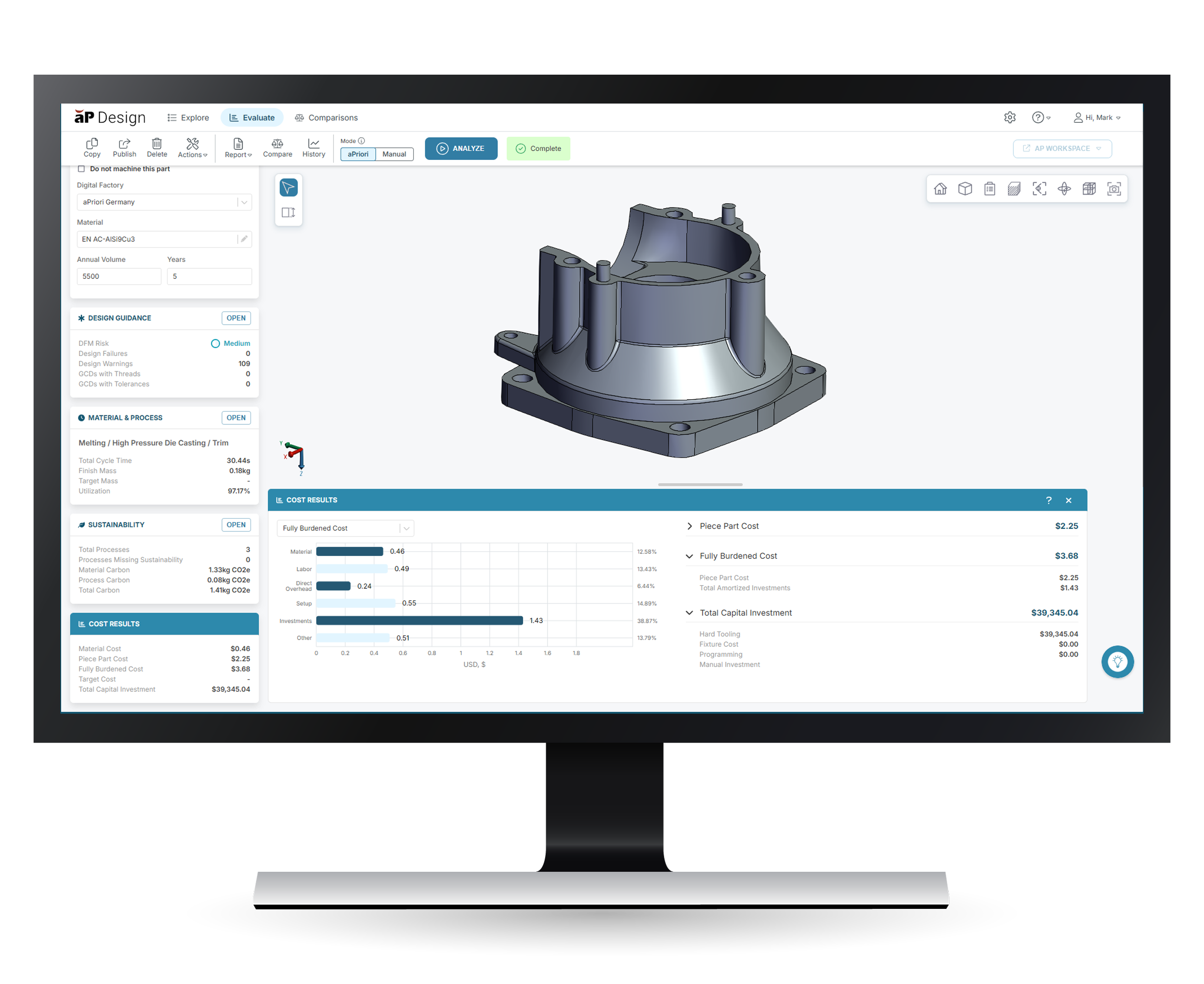

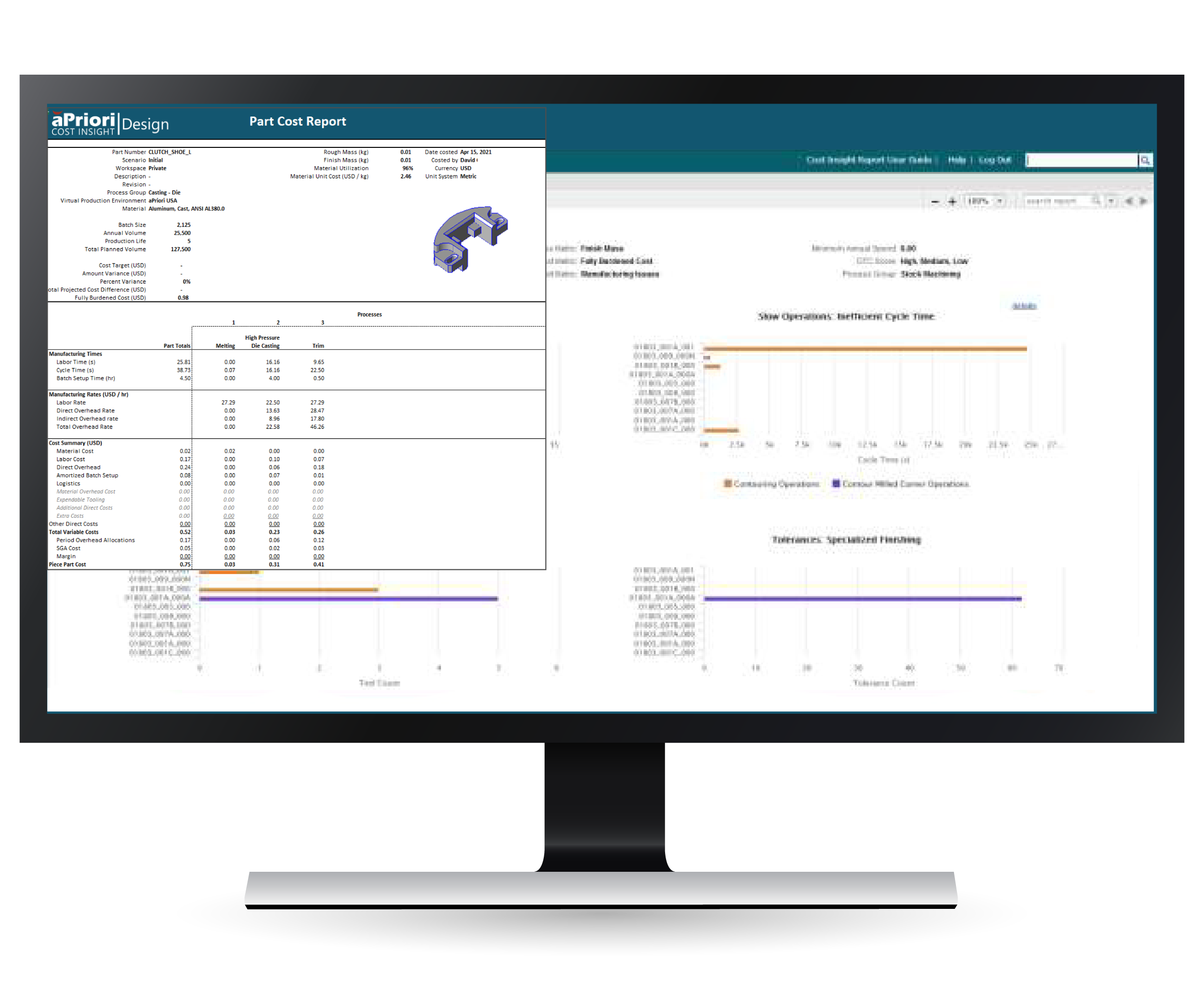

Automated Manufacturability Analysis with Design Guidance to Eliminate Cost Drivers

What if there was a way to increase the percentage of new product designs that were optimized for manufacturability and cost, and reduce the time it takes to deliver these new products to market – all without impacting the workload of your engineering team?

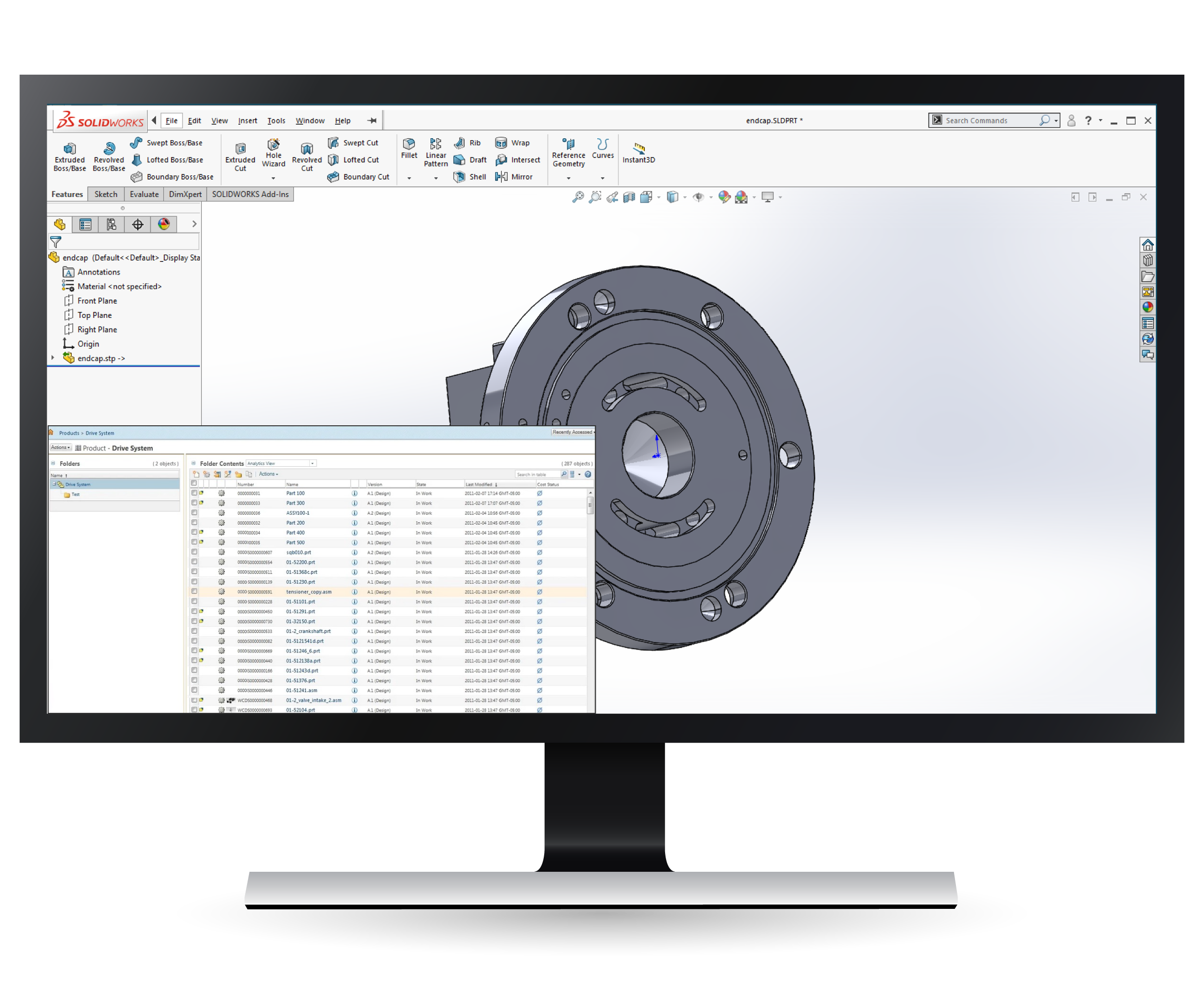

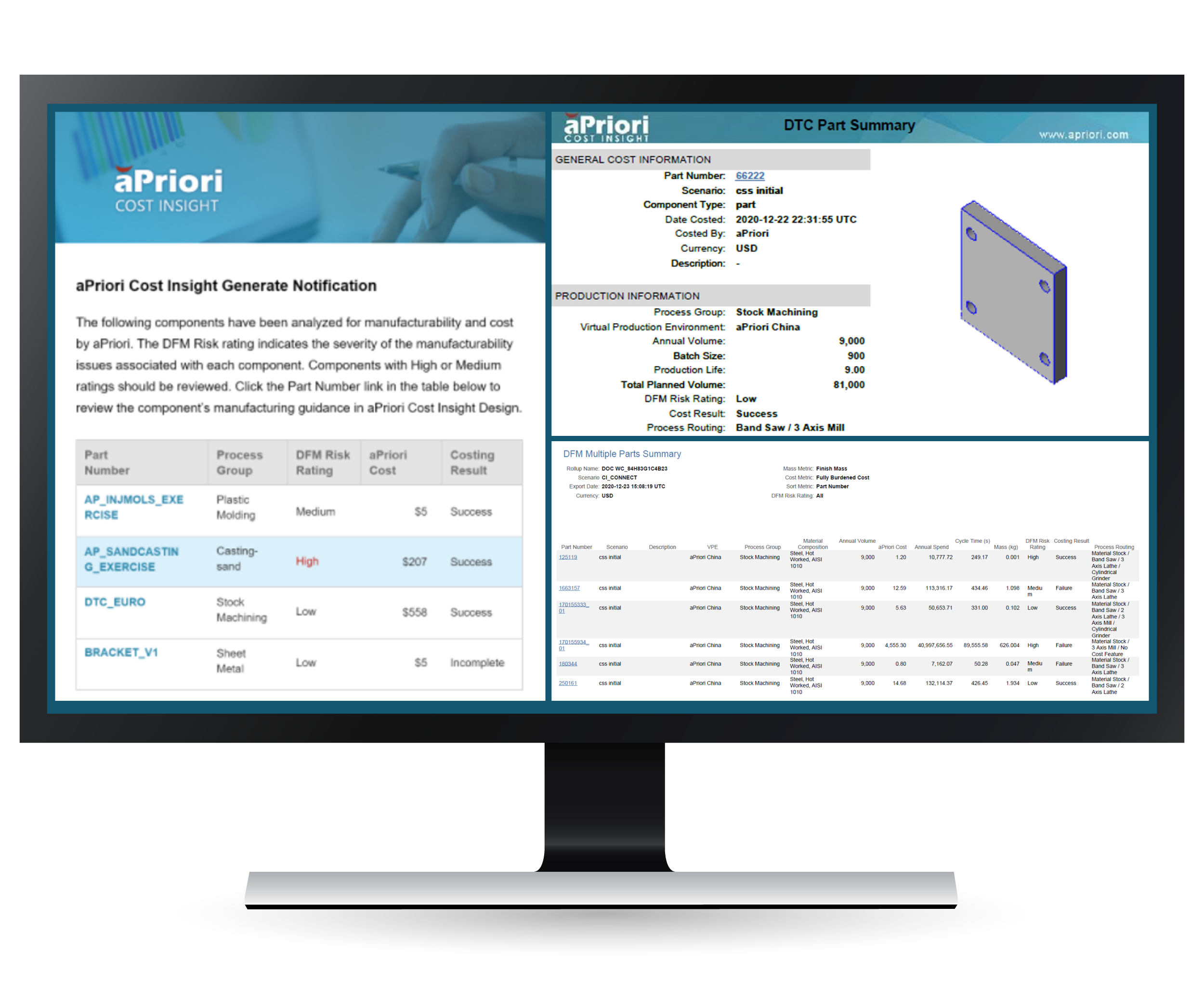

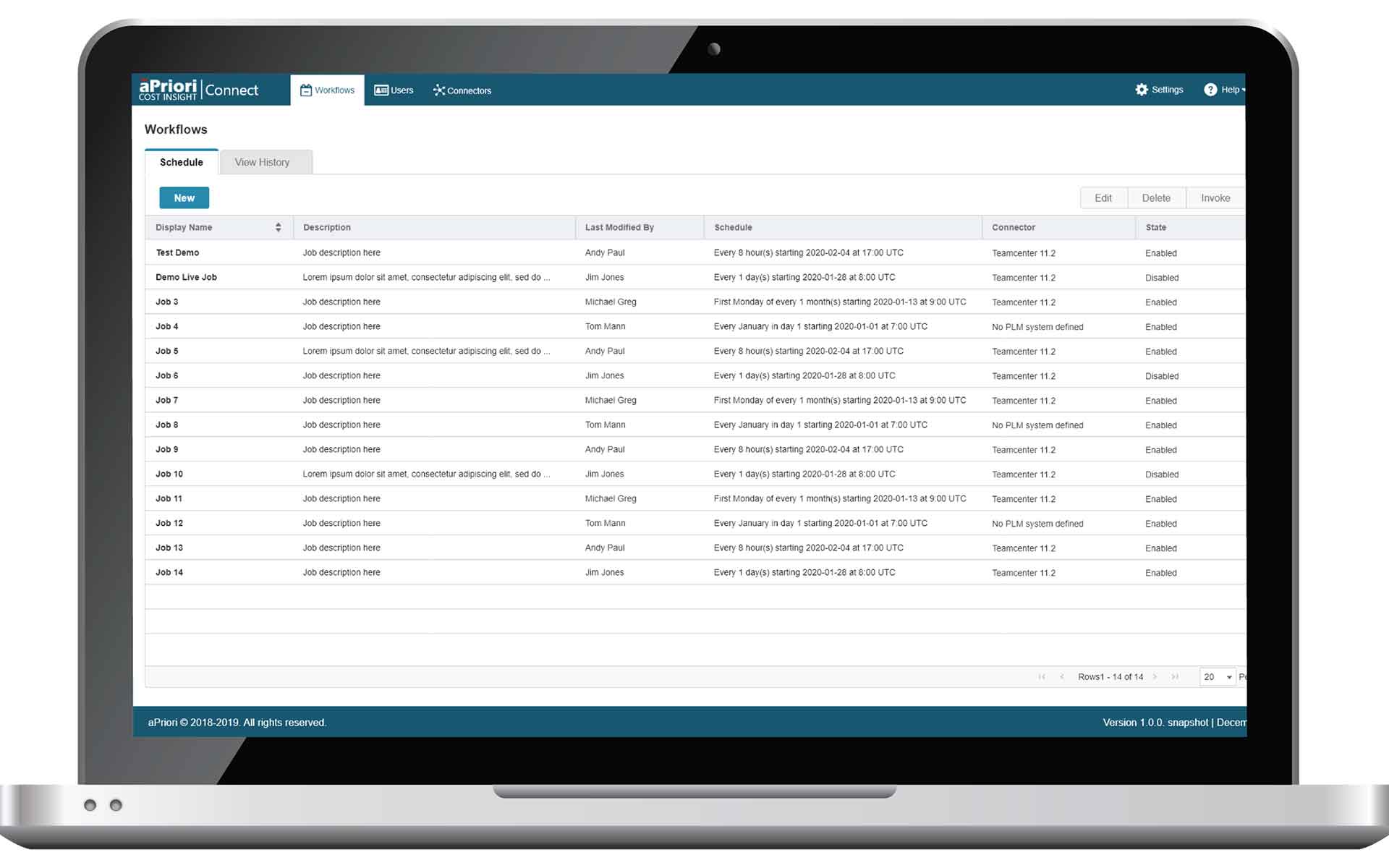

aP Generate is a revolutionary new digital manufacturing simulation technology from aPriori that works silently in the background, automatically analyzing your digital twin CAD models every time they are checked into your Product Lifecycle Management (PLM) system. No upfront work by the engineer required. The only time the engineer needs to get involved is when a potential manufacturability problem is detected by the system.

Product Features

How it works:

See aP Generate in action

Built-in manufacturability guidance makes designing to cost easier than ever. Best of all? It integrates with the CAD system and PLM you’re already using. Request a personalized demo today.

Visit our Resource Hub

Get the aP Generate Brochure

Generate manufacturability insights in minutes

Check out our Industry Guides

Before you go, drop us a line.

Can a single form submission change your life? Maybe not. But it is the start of your digital transformation.