Cost and Value Engineering

Maximize Cost Savings in Product Development & Manufacturing

Traditional costing tools like Excel spreadsheets rely on static historical data for new part estimates, limiting cost/value engineering teams. These tools need seasoned professionals to work effectively and fail to provide updated cost data amid market volatility. They also lack system integrations, hindering information sharing and collaboration, and cannot scale to meet new cost management needs.

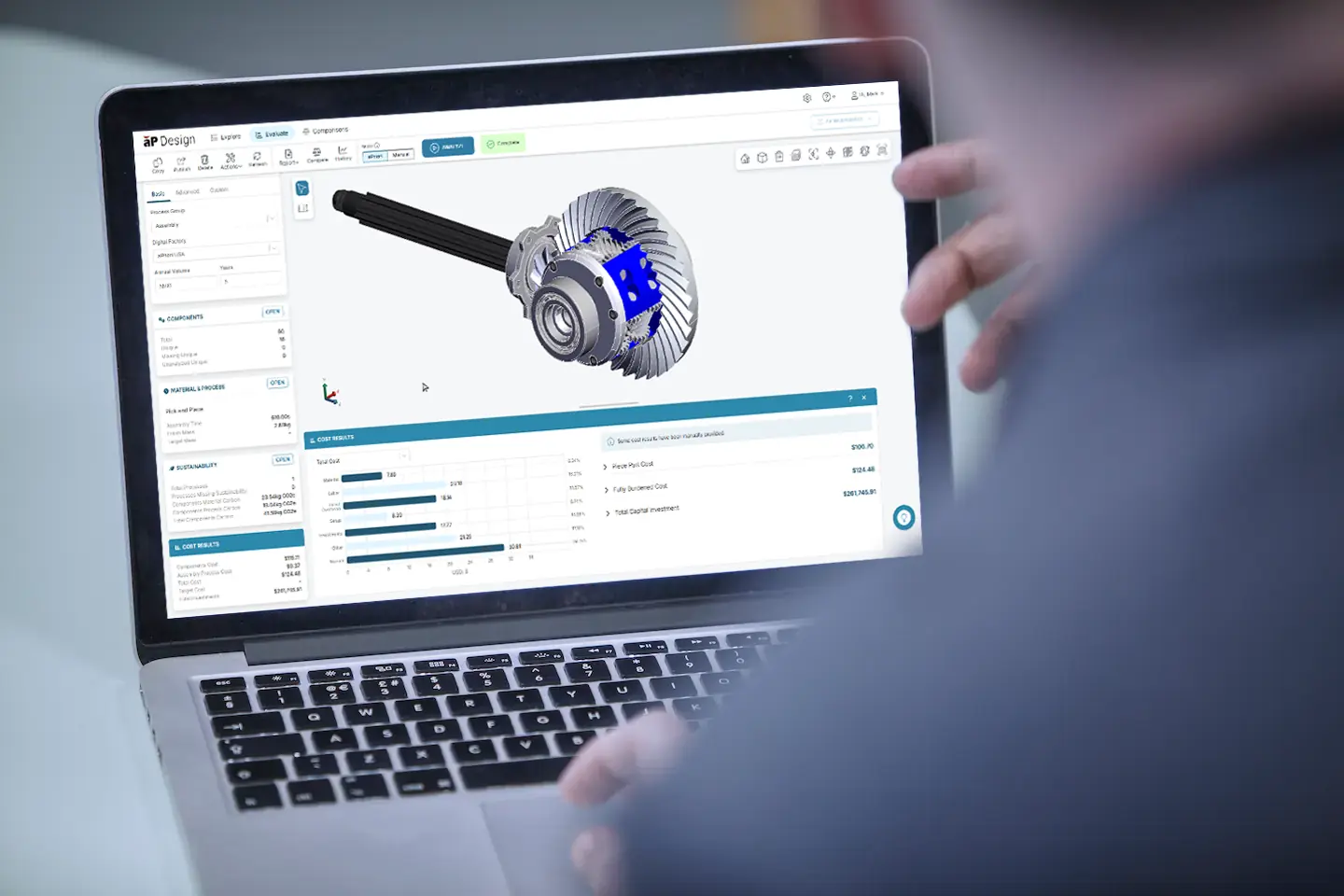

With aPriori’s AI-powered cost engineering software, you can quickly generate accurate estimates through advanced cost models and use three levels of automation to boost profitability.

Benefits

- Accurately evaluate costs for various parts/assemblies to uncover more savings opportunities and inform “make vs. buy” decisions

- Provide better support for internal requests from design engineering and sourcing teams, eliminating crucial bottlenecks

- Proactively optimize product development and manufacturing costs using detailed cost driver insights

- Shift from cumbersome, time-consuming estimating tools to a streamlined, precise cost-modeling system

- Provide actionable cost-reduction guidance throughout the product life cycle, starting from the early design stages

- Prevent late-stage, costly engineering change orders (ECOs) and meet cost and time-to-market (TTM) targets

-

Conduct productive supplier negotiations and effectively reduce costs using fact-based, data-driven insights

-

Identify and prioritize challenges not only in cost but also in sustainability and manufacturability

Master Cost Efficiency & Unlock Substantial Financial Benefits

Employ aPriori’s should cost estimates as benchmarks for supplier negotiations and cost-effective decision-making to save millions. Use aPriori to expand cost engineering expertise throughout the entire product development team to assess the cost impact of alternative designs, sourcing decisions, and manufacturing process selections.

Discover how Carrier leveraged aPriori’s advanced cost-estimating software to save $30 million in one year.

Advantages

- Gain three levels of automation: Part/Assembly 3D CAD Geometry Analysis, Bulk Costing Analysis, and PLM Integration-Based Analysis

- Generate standard or ad hoc cost reports for new or redesigned products, aligning with Design to Cost (DTC) targets

- Share real-time manufacturing data to ensure all teams are aligned on organizational cost objectives

- Create a digital twin of in-house or supplier factories to simulate various machines, materials, processes, overhead rates, and more

- Simulate different manufacturing scenarios to identify the most cost-effective options

- Utilize batch costing to increase throughput of designs optimized for cost, sustainability, and manufacturability

Cost and Value Engineering Resources

Alstom Aligns Cost and Design with aPriori

Design-Stage Cost Insight Drives Speed and Savings for CNH