Case Study

Simulated Manufacturing Speeds Up Quoting to Boost RFQ Win Rate

How can a contract manufacturer provide consistent quotes for diverse products manufactured across hundreds of facilities in a complex global supply chain?

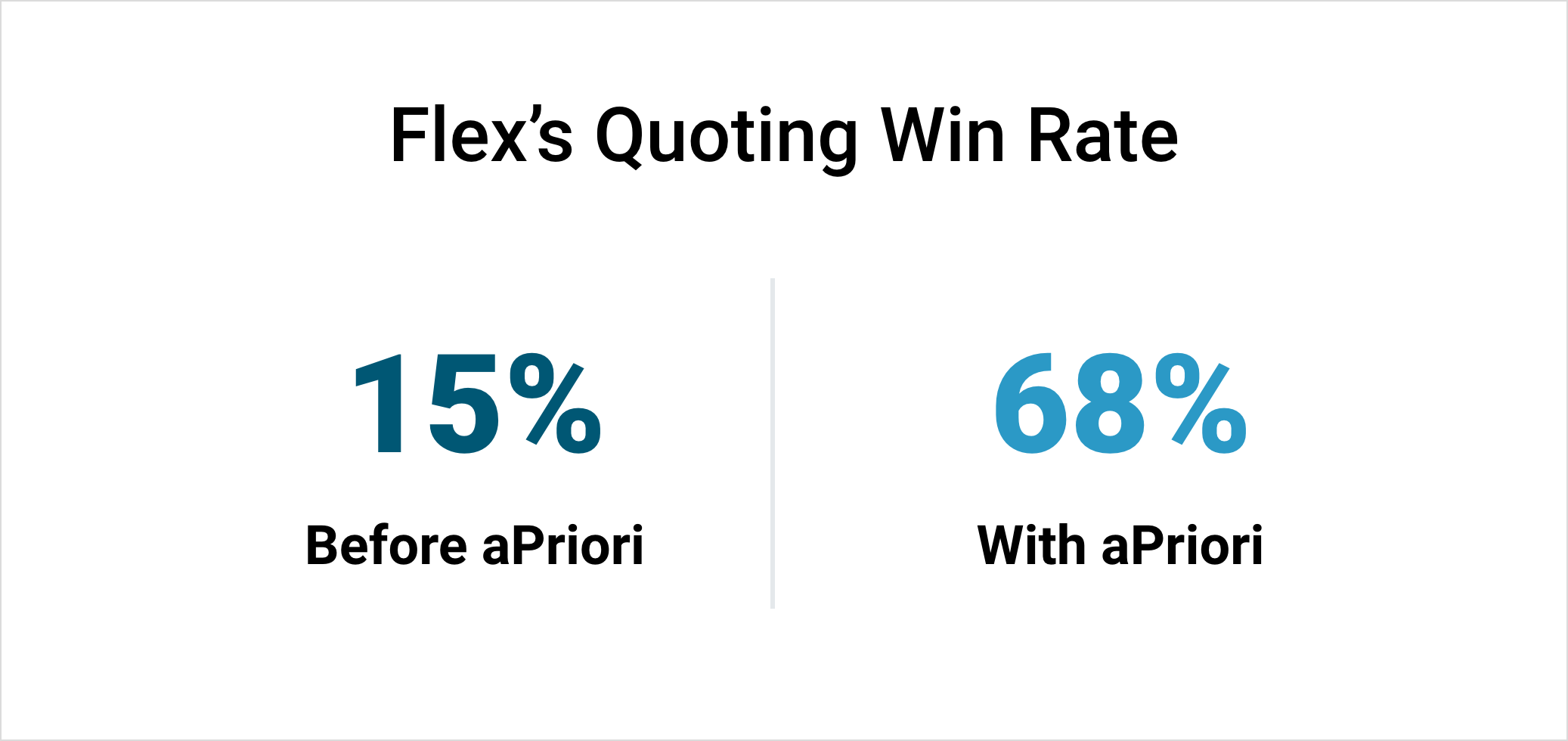

In this case study, we look at how Flex used aPriori’s digital factories to solve this challenge, dramatically accelerating their quoting process to boost their Request For Quote (RFQ) win rate from 15% to 68%.

Company Details

Industry

Manufacturing

Number of Employees

17,000

Revenue

$26 Billion

Website

aPriori Product

aP Pro; aP Analytics

The Problem

Consistent Quoting for a Complex Global Supply ChainThe Solution

Digital Factories Provide Consistent Simulated Cost Models WorldwideWho is Flex?

Flex is a contract manufacturer that designs, builds, and delivers products ranging from server storage systems, to wearable devices, to televisions. While specializing in electronics, they deliver a diverse array of products to over 1,000 customers worldwide.

To support this large customer base, Flex maintains over 170,000 employees (including over 20,000 designers and engineers and over 10,00 supply chain professionals) spread across 100 global sites in 30 different countries.

Problem: Consistent Quoting for a Complex Global Supply Chain

Flex serves just about every industry imaginable, with dozens of customers in medical, automotive, home appliances, telecom, and many more. Their diverse customers require a huge number of different designs and components. Flex manages over one million different parts, both manufactured internally and purchased from over 16,000 global suppliers. Flex’s large global operations also include many manufacturing facilities which were added via acquisition. This complexity made consistently quoting new orders incredibly challenging and time-consuming.

Flex needed to find a technology that could provide a unified approach to cost modeling across its global operations. The right solution would need to speak the language of design engineers, supply chain professionals, and quoting teams worldwide. They selected aPriori as a strong fit for all of these criteria.

Flex’s Michael Perott, Senior Global Quotes Director, explains why in the video below:

Solution: Digital Factories Provide Consistent Simulated Cost Models Worldwide

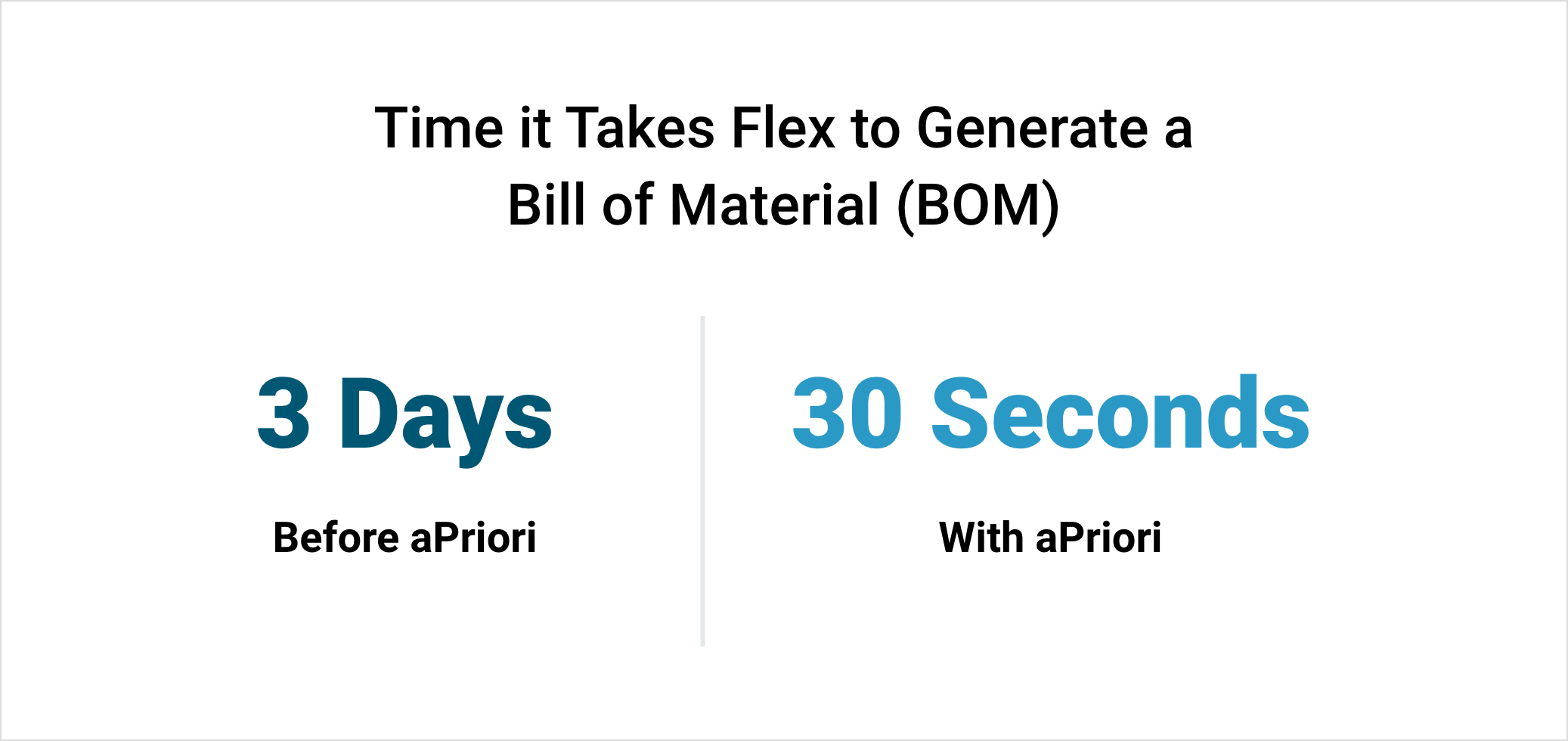

Flex initially began making use of aPriori’s digital factories for quoting mechanical parts. Before, these parts were quoted using a manual, spreadsheet-driven process that diverged heavily between sites. Different facilities employed different costing tools, and subjective quoting processes drive quoting variation that was difficult to explain to customers. Using aPriori, any Flex facility can quickly simulate manufacturing in a digital factory configured to match its unique capabilities and cost structure. The inputs for this simulation can be easily customized to reflect specific customer product parameters, allowing cost models to be readily customized for new RFQs.

This simulation-driven process is fast, accurate, and consistent, without sacrificing the ability to tailor cost models to regional differences in labor costs, energy costs, tooling capabilities, and more. Simulation-based cost models are consistent worldwide, providing Flex with the granular cost structure data needed to make well-informed business decisions while comparing sourcing alternatives in real-time.

Because aPriori dramatically accelerates the quoting process, it also dramatically improved Flex’s responsiveness to RFQs. aPriori is fully integrated with Flex’s custom internal P&L tool, allowing simulated cost models to be rapidly translated into customer-facing quotes.

Results: Consistent, Accurate Quotes Enable Higher Win Rates

After a pilot project supporting quoting work for mechanical products in Guadalajara, Mexico, proved successful, Flex began rapidly rolling out aPriori to more sites globally. Within two years of the initial pilot project, their implementation expanded to additional sites in China, Europe, and Malaysia. Today, users across Flex’s entire global organization have access to aPriori’s digital factories.

Global adoption has decreased time-to-quote by a minimum of 35% (as much as 80% for some parts). A faster, consistent, and accurate quoting process has directly translated into higher win rates for Flex. Since adopting aPriori, Flex’s overall win rate has improved from 15% to 68%.

Flex’s Senior Director of Global Quotes, Michael Perrott, shares five benefits their team has observed from using aPriori in this video clip.

After beginning with mechanical parts, Flex is working to expand its aPriori implementation to other key manufacturing specialties such as PCB assembly and plastics. They plan to work to incorporate digital factories earlier in the design process to drive further capabilities for providing value-added cost and manufacturability feedback to customers on their designs.

Listen in as Flex’s Mike Perrot provides further details on how their process benefits from aPriori in this interview.

Experience aPriori in Action

Meet with an aPriori expert and learn how we can help you to eliminate product costs, improve productivity, and reduce your carbon footprint.