Case Study

How to Utilize Manufacturing Simulation for Better Target Costing

Introduction

Product manufacturers and design engineers do not always have a clear method to communicate. In fact, in many companies, collaboration between the two groups is non-existent. But each team is responsible for target costing measures of the products that they are designing and building.

If the two teams were communicating on a shared platform, they could streamline the entire product development process and, together, meet (or beat) company target cost goals.

That’s just what Jabil did. Read this case study to learn how aPriori has completely changed the way that Jabil designers and manufacturers collaborate with each other. And how that improved collaboration has led to enormous savings for the company.

Company Details

Industry

Manufacturing Services

Number of Employees

238,000

Revenue

$34.5 Billion

Website

aPriori Product

aP Pro

The Problem

Jabil needed to streamline target costing while also improving communication between design and manufacturing teamsThe Solution

Use target costing simulation software by aPriori to meet target costs while providing seamless collaborationWhat is Target Costing in Manufacturing?

In manufacturing, target costing is a system where you set a target cost for a product before you start production. The idea is to produce the product at or below the target cost. To do this, you need to understand all the costs that go into making the product, including materials, labor, and overhead. Once you have your target cost, you can work backwards to price your product so that it is profitable.

Target cost engineers work with purchasing managers and suppliers to find the most economical way of producing the products. If needed, they will develop alternate designs using less expensive materials or processes that still meet quality standards.

By adhering to a target costing methodology, companies spend less time and money on projects that will not be profitable.

Target costing software, like aPriori, helps manufacturers identify ways to reduce the cost of a product early in the production cycle.

In fact, most of your cost modeling can be completed as soon as your design is ready for costing.

What are the Benefits to Having a Streamlined Target Costing Strategy?

There are many benefits to having a seamless and streamlined target costing strategy. Some of those benefits include:

How Manufacturing Simulation Leads to Easier Target Costing

As more and more companies embrace digital transformation to remain competitive, aPriori stands out as a leader in the product and target costing software industry.

aPriori can help by estimating what kind of savings different changes would create, like switching out an expensive material for a cheaper one.

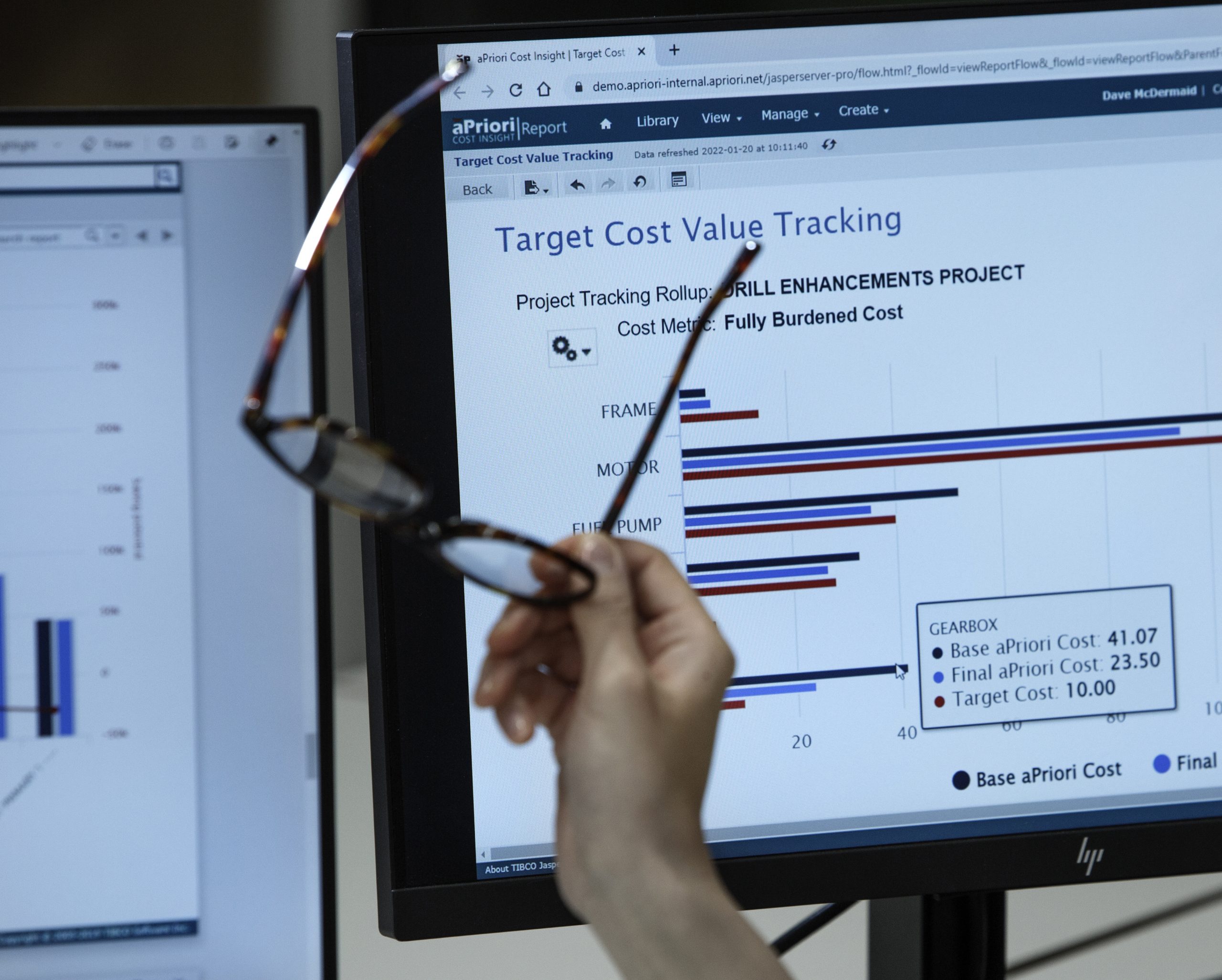

Savvy target costing and cost modeling software will allow you to build multiple digital factories for your suppliers. Enabling you to see in real time how design changes will impact your target costs.

What are the Benefits of Manufacturing Simulation for Target Costing?

- With manufacturing simulation, you can easily compare design alternatives to understand which one has the least manufacturability issues and is least expensive to produce. aPriori’s intuitive software will scan your 3D CAD model and identify material and geometry issues that will drive up product costs.

- Even inexperienced designers can benefit from sending their designs through aPriori. Because in just seconds, aPriori will use your digital factory setup to identify design features that unnecessarily drive requirements for additional manufacturing operations. When it comes to target costing, knowing where your machining and supply chain can be streamlined is critical to your bottom line.

- With manufacturing simulation, you can also uncover why a design is returning higher bids from supply chain partners than expected. aPriori’s databases can help you identify when overhead, materials, or labor costs are much higher than average. This can lead to collaborative discussions with your supplier about inefficiencies you may be over paying for.

- Timing is just as critical to target costing as the cost itself. Multiple redesigns and quotes can take weeks of time and resources. With manufacturing simulation, your manufacturing process models ensure that manufacturing issues do not surface in the later stages of the design lifecycle and hold up a time-sensitive product rollout. Not only are you meeting your cost targets, but you’re getting to market faster.

Jabil has embraced aPriori to meet product cost targets and streamline processes; creating a company-wide cost-awareness culture that everyone can rally behind.

Explore the Jabil and aPriori partnership in more detail with this short video:

Experience aPriori in Action

Meet with an aPriori expert and learn how we can help you to eliminate product costs, improve productivity, and reduce your carbon footprint.