Case Study

How Nikola Breaks the Mold in Plastic Parts Injection Molding

Accurately estimating tooling costs, including mold design, fabrication, and maintenance, is crucial as they are primary factors in the overall injection molding cost. Manufacturers like Nikola need to have insights into mold design, lifespan, and maintenance to control these expenses effectively.

To evaluate and optimize the injection molding process in real time, it is essential to integrate advanced cost models with digital manufacturing technologies. Given the complexity of the process, material variability, and data accuracy required, adopting advanced plastic parts injection molding technologies cannot be overlooked.

This case study examines how aPriori addressed Nikola’s challenges in creating accurate cost models for plastic parts injection molding, with a specific focus on tooling expenses.

Company Details

Industry

Energy and Transportation

Number of Employees

900

Revenue

$50 Million

Website

aPriori Product

aP Pro

The Problem

Complex automotive part designs, customization demands, and labor shortages hinder injection molding efficiency, requiring innovative cost and time controlThe Solution

Tackling auto design challenges through aPriori’s CAD-integrated cost models, detailed breakdowns, and regional expense comparisonsWho is Nikola?

Founded in 2014, Nikola Corporation specializes in producing heavy-duty commercial battery-electric and fuel-cell vehicles, along with energy solutions. The company is recognized for its cost-effective Class 8 zero-emissions semi-trucks, such as the Nikola One, and its electric charging and hydrogen refueling mobile solutions.

Nikola has approximately 250 electric assemblies on the road and has built 25 fuel cells within the last three months. The manufacturer has a dedicated workforce of 1,500 professionals who are primarily based in Phoenix, Arizona.

Problem: Design Complexity Raises Tool Costs and Lead Times Amid Labor Shortages

Nikola, like many other automotive companies, has encountered difficulties in sourcing and managing injection molds for plastic parts. The plastic parts injection molding process is complex and presents significant challenges, such as a shortage of skilled labor and intense competition among tool shops. Below, we provide further insight into these obstacles:

1. Increased Tool Requirements Caused by Vehicle Design Complexity and Customization

Manufacturing complex and customized plastic vehicle parts requires a significant number of tools in the plastic injection molding process. Within six months, Nikola sources approximately 2,000-3,000 tools and 150 Class-A surface parts. This process involves conducting cost analysis, identifying suitable tool shops with the right capacities, and negotiating with them for favorable pricing.

However, prices are often influenced by the workload of the tool shop and the competitive nature of bids. It becomes increasingly challenging to bid competitively as large Tier 1 suppliers usually already have agreements with tool shops.

To cater to complex vehicle designs, Nikola has spent over $40 million on more than 2,000 tools and 100 Class-A visible parts. These staggering tooling expenses are used to create molds and equipment for manufacturing several vehicle components, including the instrument panel, console, fascia, and door trim.

The primary cost drivers of the injection molding process are the size of the core and mold cavity tool blocks, as well as rough-cutting production operations. These two factors account for 30% of Nikola’s overall tooling expenses from the outset.

2. Extended Lead Times and Costs Due to Complex Parts and Multi-Step Production

Nikola’s vehicle designs are complex and require multiple procurement activities and production processes, resulting in longer lead times. To illustrate, here are examples of the manufacturing expenses and lead time issues that the innovator has faced:

- Steel Procurement and Material Selection. Acquiring large steel blocks can take up to eight weeks. This is because the material is not readily available or stocked on shelves due to its considerable size. Further, the material comes at a hefty price, costing between $50,000-$60,000 to procure.

- Sequential Valve Gate (SVG) Hot-Runner Systems. During the plastic parts injection molding process, SVG systems control the flow of molten plastic resin into a mold cavity. Implementing this method can be expensive for Nikola, costing approximately $9,500 for every 200 millimeters (mm) drop. Additionally, lead times for SVG can vary based on factors such as mold design complexities, supplier capabilities, and customization requirements.

- Rough-Cutting Operations. The injection molding process is widely used to form and shape plastic materials, primarily thermoplastics. This process requires making deep cuts into a large fascia. However, the rough-cutting process can be time-consuming, taking up to three to four weeks, with costs ranging from $75-$85 per hour in Canada and the U.S. Nikola estimates that it takes 18-20 weeks to complete the manufacturing of a fascia tool, resulting in longer lead times to produce plastic parts.

- Mold Finish and Graining Manufacturing Processes. After the core and cavity cutting process, it may take an additional three to four weeks to achieve a specific mold finish or incorporate graining into a part. This is particularly true for costly lighting tools that require a high-quality surface finish for stainless steel. For Nikola, achieving the desired mold finish and graining for a final part can cost up to $30,000 using a specialized tool.

Download and view the Extended Lead Times and Costs infographic.

3. Skilled Worker Shortages and Heightened Labor Costs

Today’s market dynamics have led to a rise in labor costs and a shortage of skilled workers in tooling. Consequently, Nikola faces difficulties in navigating the injection molding process, where factors like cycle time and volume production of molded parts determine manufacturing feasibility and expenses.

To remain competitive in the market, Nikola needs to assess the varying labor costs and hourly rates in different regions of the world. For instance, Nikola estimates that the cost of the rough-cutting process can go upwards of $80 per hour. However, in countries like China and India, this same process is offered at a low cost, with hourly rates of around $25.

Ideally, Nikola would like to partner with a tool shop that has machines capable of simultaneously cutting the core and cavity in injection molding. This could increase the production capacity of the tool shop without increasing the need for skilled labor and associated costs. Unfortunately, only a few tool shops possess machines capable of delivering this desired level of precision and efficiency.

Solution: aPriori CAD-Integrated Cost Models and Granular Breakdowns Inform Decisions

Nikola has been utilizing aPriori’s Manufacturing Insights Platform, which provides advanced cost modeling capabilities, for more than three years. During the 2023 Manufacturing Insights Conference, Richard Morabito, Senior Manager of Cost Engineering for Nikola, highlighted the benefits of employing aPriori. These advantages include the following:

- CAD-Integrated Cost Models. aPriori automatically evaluates the geometry of 3D CAD designs and provides estimates based on real-world factors like raw materials, production expenses, and more. With aPriori’s advanced costing capabilities, Nikola has identified the top-10 cost drivers in injection molding, including steel types, rough cutting, mold finish, and gate types. Nikola also uses aPriori to set cost targets, conduct feasibility checks, and perform preliminary mold flows.

- Granular Tooling Cost Breakdowns. After refining the aPriori module and inputting variables into the tool, Nikola quickly identified 50 negotiable items. Additionally, the manufacturer discovered potential opportunities for expedited tool production and favorable pricing, inclusive of mold trial costs. Further, Nikola can utilize aPriori’s should cost modeling technology to identify cost-saving opportunities, such as selecting more economical alternative materials.

- Regional Cost Comparisons and Detailed Pricing Insights. aPriori enables Nikola to compare tooling costs in various regions like China, Canada, and India. This helps the manufacturer understand optimal pricing for parts across multiple regions (87 total), considering factors like tariffs before issuing RFQs. Moreover, aPriori provides upfront details on piece prices, cycle times, labor costs, and machine burden rates to expedite data-driven decision-making.

Results: Saved Millions on Tooling Using aPriori Cost Models

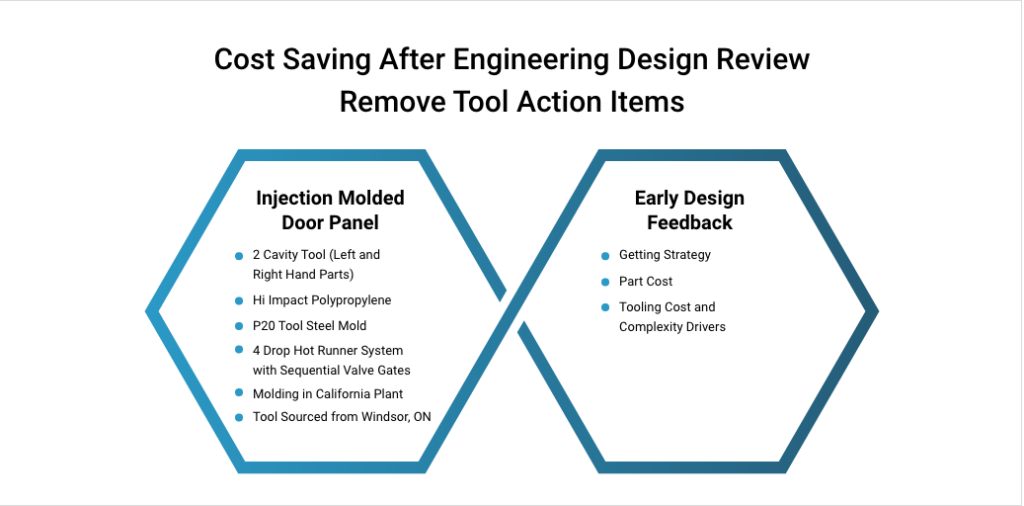

Nikola achieved impressive results by utilizing aPriori and its expert services team to optimize the cost of an injection-molded door panel with four expensive slider parts (Figure 1). By making slight design modifications, such as replacing armrest holes with slots, the manufacturer was able to save $38,000 on this component alone.

Fig. 1. An example of Cost Savings After an Engineering Design Review.

Additionally, Morabito reported that aPriori has enabled his cost engineering team to obtain a piece and tooling estimate within an hour. He has also experienced tooling cost savings of up to 30% at Nikola and in companies where he implemented aPriori during the first year.

Moving forward, Nikola will continue to rely on aPriori’s robust cost modeling capabilities to address rising capital expenses and navigate an imminent workforce gap in tool and die manufacturing.

Hear more about how Nikola uses aPriori’s plastic parts injection molding cost models to capture significant savings:

Experience aPriori in Action

Meet with an aPriori expert and learn how we can help you to eliminate product costs, improve productivity, and reduce your carbon footprint.