Using Digital Twins & Supply Chain Automation to Drive Decision Intelligence

Key Takeaways:

- Product development teams must do more with less, and procurement and sourcing teams must manage many moving parts while mitigating risk, reducing inefficiencies, and delivering savings and time to market

- Digital twins can drive the benefits of supply chain automation, improving decision-making and creating a more agile, robust supply chain

The Full Article:

Sourcing and procurement teams: Less capacity. More resource constraints. Greater risk and unpredictability. Sound familiar?

Consider these statistics:

- McKinsey estimates that over the next five years, approximately $30 trillion in corporate revenues will depend upon products that have yet to reach the market. This puts a lot of pressure on downstream teams (like procurement, operations, production, and supply chain) to handle the last-minute challenges.

- According to The Hackett Group, Chief Procurement Officers (CPOs) report procurement organizations will have an increased workload of 8% and a productivity and efficiency gap of 6.6% and 6.4%, respectively.

These teams can no longer focus on cost savings to the exclusion of everything else. Instead, they have become critical factors in strengthening the entire supply chain operations—from cost, innovation, sustainability, and time to market to better decision-making, procurement strategies, and continuous improvement.

However, they are dealing with many downstream challenges. Limited resources, parts prioritization, and revenue opportunity identification are a few examples. These challenges are coupled with various risks, including not being able to proactively mitigate supply chain process issues, identify the right cost drivers to leverage during supplier negotiations, send RFQs to the best supplier with the right capabilities to speed up time to market, and circumvent supply chain shortages and disruptions due to a lack of timely supply chain information.

Four Goals to Unlock Greater Supply Chain Value

There are four goals manufacturers can strive for to gain more value from their global supply chains. They are:

- Utilizing automation for time and resource scalability. Artificial intelligence (AI)-powered tools help procurement teams extend their capacity, ensuring better outcomes with fewer resources

- Filling the pipeline. The ability to identify more opportunities for cost reduction, supplier rationalization, and batch optimization enables teams to fill their opportunity pipeline, achieving more than savings without a lot of resources

- Mitigating risk and quickly removing bottlenecks. Managing risk (including those due to human error) by running what-if scenarios that quantify the cost of those risks and alternative outcomes that remove potential supply chain bottlenecks during times of disruption

- Collaborating faster and more efficiently, creating a cost-efficient culture. Sourcing and procurement teams need to be part of agile product teams and have ways to collaborate efficiently, fostering a cost-conscious culture that leads to faster time to market and more agile teams working from the same data

Most successful organizations can realistically achieve these goals. The CPO can be instrumental in this process by driving these initiatives and ensuring goals are met.

Additionally, it requires building an ecosystem of continuous improvement—doing more with less time and resources. For example, procurement, sourcing, and quoting teams need to reduce costs and mitigate the risk of being late to market.

In our 2023 State of Manufacturing Procurement Report, 69% of those surveyed reported that the sourcing, quoting, and procurement process takes three to ten weeks to complete. In some cases, faster time to market will even take precedence over lower costs since many missed RFQ win opportunities are due to quoting lags. In fact, 60% of those in the procurement survey noted that complex bid packages are the primary reason for sourcing delays.

Building Better Data Sharing for Streamlined Processes and Collaboration

Supply chain automation solutions are essential to streamlining workflows and enhancing decision-making, collaboration, time to market, and more. However, the many teams and moving parts can hamper these goals.

Sourcing and procurement need to collaborate with design engineers, various suppliers, the sustainability engineer, and the cost engineer.

Our Procurement report indicates that sourcing and procurement are often executed ad hoc, with 70% relying on email for collaboration and 52% using spreadsheets. However, 70% recognize that data standardization should be a priority.

Improve Planning with Fact-based Insights

A strategic plan for strong supply chain management relies on accurate, detailed, consistent, and centralized, real-time data for your product, manufacturing cost models, and regional data libraries.

Executives can use this data for planning and analysis scenarios, including:

- Replacement material viability evaluation to circumvent supply chain delays

- Comparison of various manufacturing processes’ production costs and availability

- Matrix costing to compare regional manufacturing cost differences by labor, materials, overhead, equipment/facility rates, and profit margin

- What-if scenarios planning for potential market changes

Digital Twins = Manufacturing Optimization

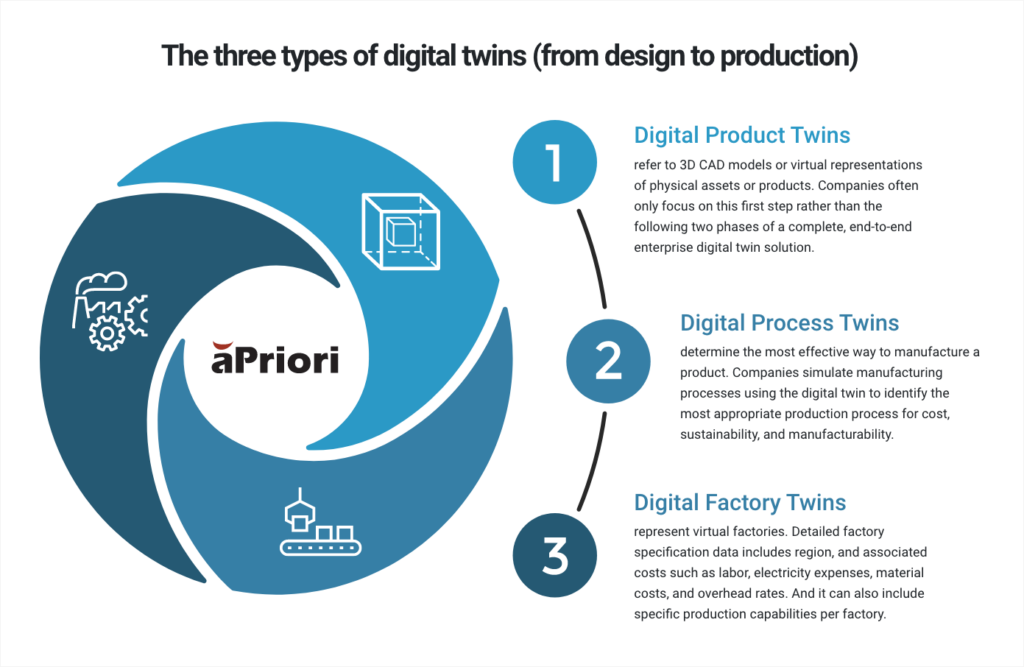

Digital twins can be leveraged from design through production (see the chart below for a detailed explanation). Not only can manufacturers find hidden costs and manufacturability issues through simulation.

They can streamline the entire development process, including collaboration, verifiable data collection, and supplier relationship management. As a result, all teams can more effectively forecast and make informed decisions faster. RFQ response times lead to an accelerated product launch.

Two Supply Chain Automation Success Stories

Challenge: Procurement team members used individual cost-reduction strategies (non-standardized Excel models) rather than one standardized method. Manual tasks or manual processes like cost estimation methods are time-consuming, making it difficult to democratize analysis for should cost.

Solution: aPriori’s AI-powered insights democratize should cost analysis. This automated should cost analysis enhances product analysis coverage making should cost readily available for all stakeholders through a single request application.

Quantified Results: Users gain a fast, automated, single, and standardized methodology, boosting innovation and cost efficiency. The customer was able to increase part analysis from approximately 1000 parts/year to 10,000+ parts/year across the entire organization. Through aPriori’s solution, should cost and quoting clarity and consistency boosted productivity and lowered the company’s costs.

TE Connectivity Establishing Cost Transparency

Challenge: Energy costs increased by as much as 300%, leading one of TE Connectivity’s suppliers to increase the machine rate by 10%. Additionally, production costs increased by 30% over the prior three years. Finally, labor and manufacturing quotes in a supplier’s country of operation are 2X the regional average.

Solution: Due to ongoing market volatility and increased supplier expenses, assessing and reducing critical product costs was essential. More proactive supplier relationship management (SRM) was enabled, unlocking significant cost savings with data-driven expense analysis.

Quantified Results: Leveraging aPriori, it was determined that the 10% machine rate increase was unreasonable. Additionally, aPriori identified that just 4% of the machine rate impacted the product. The company also reduced raw material costs by 15%. Finally, aPriori’s clear talking points support discussions and negotiations with suppliers, ensuring better pricing for the customer.

Digitization Paves The Way For a Faster, More Robust Supply Chain

Forward-thinking manufacturers understand that supply chain automation technologies are the path to greater agility, innovation, time to market, and more. Manufacturers can quickly and securely share information with suppliers to accelerate the process. As a result, manufacturers will:

- Leverage the digital twin and digital thread in the RFQ process, saving time, increasing quoting accuracy which reduces the time it takes to receive a quote, and accelerating time to market

- Gain “Zero RFQ” capabilities by sending purchase orders (POs) directly to preferred and suitable suppliers automatically, resulting in shorter product timelines

- Enhance digital sharing using PLM tools and other critical systems like enterprise resource planning (ERP), closing product system of record and procurement system of engagement gaps. It is further amplified with robust product data from all existing systems connected by the digital thread, accelerating time to market and reducing risk.

Finally, using a digital platform simplifies collaboration across product development, eliminating unwieldy email chains, time lags, and inconsistent data. Real-time visibility and manufacturing collaboration software, like aP Workspace, access critical product information and enhance project visibility, traceability, and coordination.

Unlock More Product Value with Digital Factories

Get real-time, AI-powered manufacturing insights to streamline and accelerate the product development cycle, and optimize design, cost, sourcing, and sustainability