Zero RFQ Best Practices for Strategic Sourcing

Key Takeaways:

- Manufacturers require “digital procurement” capabilities to manage dynamic changes as well as cost and component availability

- The right quoting tool can identify and remediate high product costs early and streamline the supplier purchase process

The Full Article:

Time is money for manufacturers. Price Waterhouse Coopers noted in a supply survey that 83% of executives say their supply chain technology investments haven’t fully delivered expected results, while 65% say managing and reducing costs was a top priority.

Request for Quotation (RFQ) is an arduous process. Frequently, it results in an often-overlooked source of delays and time-consuming manual processes. There is the challenge of aligning design and cost. Suppliers and manufacturers need a transparent and collaborative tool that provides a central database from which they can better understand design intent and address manufacturability issues that impact cost. Working from the same data allows them to reach a mutually beneficial agreement when it comes to parts and pricing, leading to a more seamless procurement process and a stronger working relationship. If cost and manufacturability are not considered in the design phase, it can create delays as the design engineer and supplier go back and forth. It also can lead to multiple design iterations and further slow the quoting process. If quoting is done manually, it is laborious and slow. Additional delays occur due to back and forth on supplier pricing and/or trying to pinpoint the best supplier with the right parts at the right price.

The result often is slower time to market, increased design iterations, and overpaying for supplier parts. Manufacturers need to streamline the quoting process while ensuring alignment with the right suppliers, parts, and pricing.

What is Zero RFQ?

Automating component procurement via a strategic supplier can remove the need to submit an RFQ. It is also known as “Zero RFQ” and streamlines sourcing. Instead of submitting an RFQ to suppliers, manufacturers can foster supplier relationships and send their purchase orders directly to preferred, qualified suppliers automatically. Consequently, they eliminate the RFQ process altogether and can more efficiently shorten their procurement timeline.

Since all product development team members are working from a central database, there is enhanced collaboration, increased ability to detect and address design, cost, or sourcing issues more proactively, meet cost targets, and accelerate time to market. Additionally, because the right supplier providing the right parts at the right cost is identified upfront, there is no need to go through RFQ gyrations in identifying the optimal supplier. The manufacturer partners with one supplier, eliminating the need for quotes. The icing on the cake is that this process is automated, saving time and money while ensuring the ideal partnership.

Now, an aPriori customer like Alstom can leverage a highly accurate cost model to send a purchase order directly to their well-matched supplier. It underscores the power of a solid product costing tool and the ability to develop a strong supplier relationship, allowing the manufacturer to bypass the RFQ process completely.

How to Incorporate Zero RFQs into the Strategic Sourcing Process

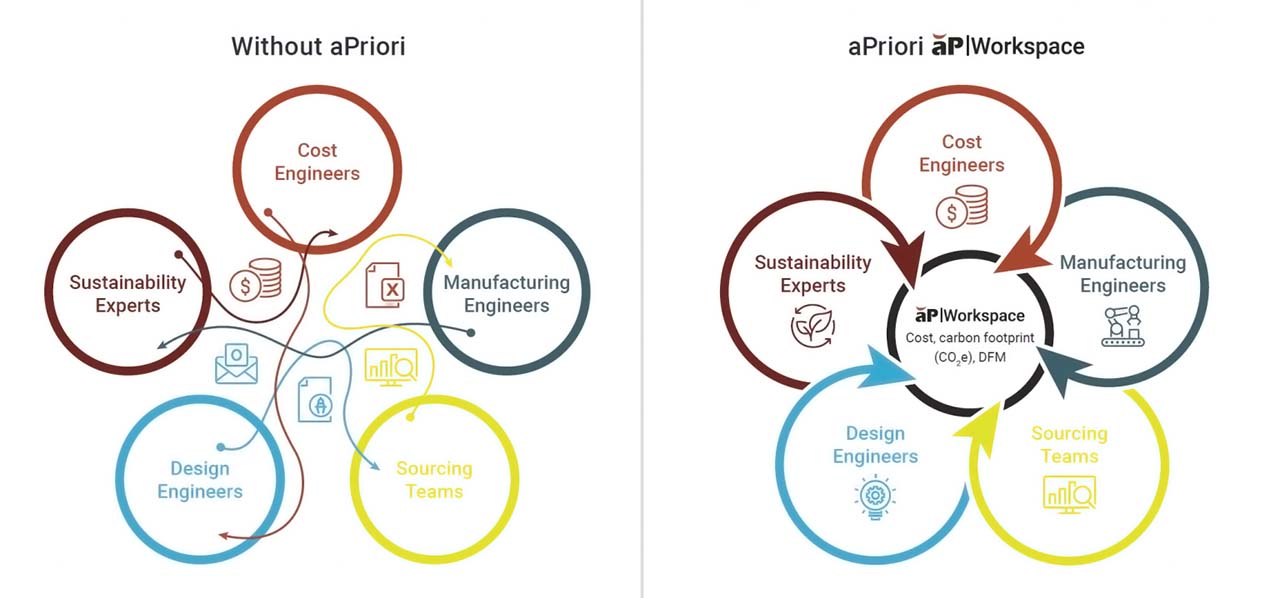

As noted above, Zero RFQ can enhance a manufacturer’s strategic sourcing process. However, it will be more achievable if manufacturers first optimize their internal collaboration strategy. It requires all product development team members to work from the same database to enhance communication and collaboration. A user-friendly tool like aPriori leverages a manufacturer’s 3D CAD model and directly imports it into the manufacturing insights platform and then data insights can be viewed and collaborated on through aP Workspace. Keep in mind that aP Workspace is for internal product manufacturers to optimize design for manufacturability. Once it’s achieved, they can share and openly discuss it with suppliers in a more transparent fashion. As a result, both manufacturer and supplier can agree or modify key cost and manufacturing assumptions to reach spec and pricing consensus. The latter provides the framework for the RFQ process.

The design engineer can see how their design impacts cost, highlighting detailed breakdowns for them. All spend categories – labor and material rates, overhead, profit margins, etc. – can be examined. If necessary, design and cost assumptions can be addressed to meet targets without compromising quality or impeding time to market. At the same time, the cost engineer also has access to these design and cost insights. If the design is cost-prohibitive, the design engineer can identify the issues early as well as facilitate continuous improvement of the product, reducing the need for multiple iterations or engineering change orders (ECOs). It also enables a high-quality product via early design refinement. Teams can rely on design, cost, and manufacturing feedback history throughout the product development lifecycle. Once the design aligns with cost targets, the manufacturer can identify the right supplier. This data then can be shared with the supplier. Doing so not only fosters greater transparency in terms of fair pricing but also nurtures a manufacturer-supplier relationship built on trust since the ultimate goal is ensuring a win-win scenario.

The manufacturer is equipped with accurate, fact-based supplier pricing data as well as a true understanding of where those costs should be. Additionally, this data can be used to quantify costs with stakeholders. Once the optimal supplier is determined, the purchase order can be submitted to the supplier. This streamlined, transparent sourcing process reduces quoting times and strengthens supplier relationship management since both manufacturer and supplier are working from the same digital factory inputs and more accurate pricing.

Aside from saving time and money, Zero RFQ has added benefits. Decision-making is more informed and faster. A more proactive stance can be taken regarding supply risks and shortages via global sourcing by comparing material rates and other supplier information from 87 regions with aPriori’s Regional Data Libraries.

Zero RFQ Best Practices for Strategic Sourcing

Now that you know the benefits of Zero RFQ, what are the right strategic sourcing methods for it? Here are five best practices that should be a part of your strategic sourcing solution:

- Identify the most suitable parts for Zero RFQ. Not all parts – particularly in early product development – will be ideal for Zero RFQ. However, parts that are a commodity or ones that are less complex serve as a great starting point to achieve Zero RFQ.

- Eliminate spreadsheet quoting with automation. Collaborate with suppliers to configure digital factories that reflect each supplier’s cost structure and enable near-instant quotes without sacrificing accuracy or losing time.

- Reduce costs and get more accurate supplier pricing. Use digital manufacturing simulation tools combined with a sourcing strategy to model manufacturing costs for myriad and varied components, providing a more detailed spend analysis.

- Cultivate supplier relationships. Working towards Zero RFQ via strategic sourcing and a digital manufacturing solution provides prime opportunities to identify potential suppliers and refine your procurement process. Consequently, procurement professionals can build stronger, long-term relationships with suppliers to foster trust and collaboration.

- Create greater agility and accelerate time to market. By eliminating traditional RFQs for select components, manufacturers can compare and more accurately forecast costs, and make sourcing decisions with simulated quotes from a variety of suppliers without triggering delays.

These best practices can help manufacturers streamline their sourcing process, reduce lead times, and improve cost efficiency.

Chief Procurement Officers’ Focus on Strategic Sourcing

The benefits of strategic sourcing cannot be understated. A McKinsey article cited one Chief Procurement Officer (CPO), “The CPO is not only the chief procurement officer anymore, but the chief partnership officer as well—partnerships externally with suppliers and internally with other functions and business units—with procurement being a knowledge broker, creating value from the collaboration between inside and outside of the company.”

A single set of data is required for collaboration and decision-making, and to ensure alignment of goals between procurement, cost engineers, and suppliers. aPriori provides visibility across the product development lifecycle to optimize designs for cost, manufacturability, sustainability, and individual factories. This level of insight is critical to pinpoint areas for continuous improvement and enable greater agility in their supply chain management, forge stronger supplier relationships, gain a competitive advantage, and enhance their cost savings.

Plagued By Slow Supplier Quoting Times?

Eliminate Wait Times, Respond Faster, Get More Consistent Pricing