Supplier Data Consistency Improves Sourcing Decisions and Manufacturing Costs

Key Takeaways:

- Lack of accurate supplier data impedes decision-making and impacts manufacturing costs

- Digital solutions like aPriori fine-tune should cost models and enable fact-based supplier negotiations

The Full Article:

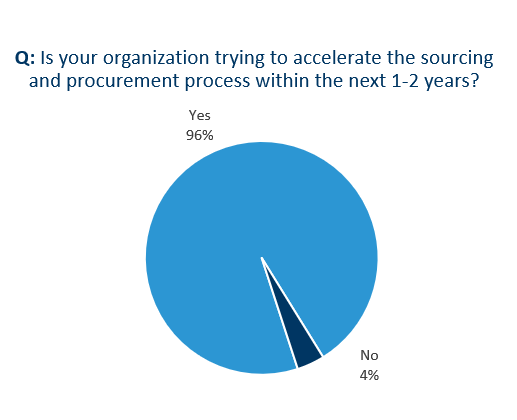

IndustryWeek’s The Need for Speed: The State of Manufacturing Procurement report for aPriori highlighted the need to improve manufacturer-supplier collaboration. It found that 70% of OEMs surveyed cited data standardization as one of their most pressing issues. What’s more, 68% agreed that there needs to be a better connection between manufacturer and supplier data systems.

Supplier Data Barriers that Impede Decision-Making

These findings underscore the importance of better data quality, analytics, and sharing. However, too many manufacturing operations still face barriers that impede decision-making as well as the ability to lower manufacturing costs. Let’s examine them:

- Too many tools with no clear consensus. Typically, organizations will implement technologies as needs arise rather than taking a comprehensive approach. Sourcing may rely on one set of analytics to make decisions, while cost engineers focus on another. As a result, there is no clear consensus on the most accurate and detailed data to make sourcing decisions and reduce costs.

- Siloed, fragmented information. Too many tools without clear consensus lead to information siloes. How can the best sourcing and cost decisions be made if all product development teams cannot access let alone consider all pertinent data? How can sourcing quickly identify material cost issues if they lack access to the necessary tools? Conversely, how can cost engineers forecast material costs if they lack insight into the supply chain and associated suppliers?

- No standardization and collaboration on task management efficiency. Siloes impede collaboration. Lags in receiving critical data and feedback also lead to inefficient task management. The problem is exacerbated if there are no standard practices or uniform technologies in place to streamline communication and collaboration. The 2022 Gartner Digital Worker Experience Survey found that almost 80% of surveyed workers were using collaboration tools in 2021. It is a nearly 30% increase from 2019 and emphasizes the importance of collaboration and task management.

- Lack of language standardization and consistency for efficient data collaboration. If your organization is not utilizing the same data, in the same language, and using the same collaboration processes, then there is no clear consensus or means for identifying disjointed data insights that lack validity. In fact, the IndustryWeek report also noted that 70% of respondents use email for sourcing and procurement collaboration. Additionally, without cloud-based data sharing, institutional knowledge can be lost.

- Customer resistance to reduplicating supplier information. Who wants to reinvent the wheel in today’s harried business climate? Certainly, not customers who continuously have to reduplicate supplier information. Not only is it time-consuming but also prone to costly errors.

- No leverage to negotiate. Knowledge is power – an essential tool in negotiating effectively. Lack of negotiation leverage or a less-than-accurate pricing portrait results in overpaying. Fact-based supplier negotiation can help reduce manufacturing costs.

aPriori’s Manufacturing Insights Platform Improves More than Supplier Data

With a manufacturing insights platform like aPriori, you foster greater collaboration and streamline workflows across the product lifecycle. You also get access to more accurate, detailed sourcing data. You will be able to optimize supply chain management, enhance product development, and accelerate time to market.

With comprehensive, fact-based data in hand, you’ll be able to make informed decisions faster, improve supplier collaboration and negotiation, and save money – all in a considerably less amount of time than traditional channels. To gain an even greater competitive edge, aPriori facilitates supplier engagement early in product development. As a result:

- Potential manufacturability issues are nipped in the bud, decreasing engineering change orders (ECOs) that impact cost and add delays.

- Manufacturers can use fact-based supplier negotiations. A win-win since the manufacturer secures a competitive price, while the supplier maintains a fair price point. More focused negotiations provide reasonably priced parts upfront, eliminating back and forth over an unrealistically low price.

- Better search abilities for suppliers to understand the capability requirements the supplier needs through process routing. Regional Data Libraries in nearly 90 geographic regions analyze the most prudent supply chain routes, reducing supply chain disruptions and facilitating better supplier connections faster.

The above attributes help to streamline sourcing, costing, and ultimately, the manufacturing process. As a result, manufacturers gain a significant competitive advantage – not only in cost savings – but time to market as well.

See how one aPriori customer reduced its supplier costs by 40%.

Taking Supplier Data a Step Further

Once the sourcing team has amassed supplier information, the next step is conducting a should cost model. It is calculated in tandem with the supplier information and supports the supplier negotiations for new parts. It is a forecast of the total cost (direct labor, raw or indirect materials, manufacturing overhead costs, desired manufacturing profit margin, etc.) of a given component if efficient manufacturing and distribution practices are considered and followed. Collaboration and proper data analysis ensure should cost optimization.

Though a should cost model can be calculated on a simple spreadsheet to tally estimated costs, it can be time-consuming and vulnerable to human error. It is especially true if product development goes through several design iterations. In that case, visibility into design iteration progression also is important to ensure you reach target goals and have insights into what necessitates those design iterations for current and future product use. aP Generate can analyze data automatically with each new design iteration consideration checked into PLM. Moreover, 71% of manufacturers in the IndustryWeek report acknowledged that regular should cost analysis is very important to their operations.

Instead, digital manufacturing simulation software such as aPriori analyzes key cost drivers at a far more granular level. Utilizing a digital solution with detailed manufacturing insights from design and sourcing through costing and the production line ensures a more accurate should cost model. Design iterations are reduced. Sourcing can be more deliberate in acquiring raw materials and components. Quoting times decrease (often from weeks to days or even minutes) and manufacturability issues and costs are addressed early in the process.

Bear in mind that there typically will be a margin between “will cost” (the actual cost to procure components) and should cost since not every cost issue can be mitigated. However, the size of the margin provides a valuable comparison point between potential suppliers. Additionally, should costs may include long-term supplier cost reductions when negotiating contracts. Finally, a material price might be lower. However, an alternative manufacturing process might offset that material price, resulting in less total manufacturing cost savings.

Learn more about how KONE uses aPriori to enhance its entire should costing methodology.

Eliminating Procurement Risks with the Right Supplier Data

A Deloitte 2023 Global Chief Procurement Officer Survey indicated that cost/spend risk (inflation) (89%) and supply shortages (79%) were the top two issues that had a high or moderate impact on their organizations over the past 12 months.

It underscores the power of solutions like aPriori to mitigate supply chain and inflation issues. The more detailed, accurate, and consistent supplier data is throughout product development, the better-positioned manufacturing businesses will be to act quickly and decisively. Supplier relations and negotiations will improve, and total manufacturing costs will be better aligned to ensure profitability.

Leverage The Power of Should Cost Analysis

Gain more effective, fact-based supplier negotiations, improve design, and get to market faster.