Nearshoring: A Solution to Supply Chain Risk Management?

Key Takeaways:

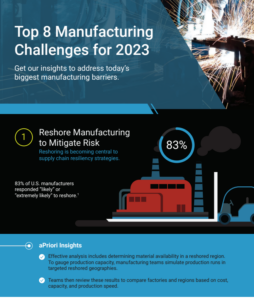

- Many U.S. manufacturers are considering nearshoring to address supply chain risk management

- aPriori’s manufacturing insights can provide detailed, real-time supplier data to work in tandem with your nearshoring program

The Full Article:

Although supply chain bottlenecks have subsided post-pandemic, continued uncertainty has left many manufacturers reevaluating their supply chains and overall business models. One consideration is whether they should nearshore – utilizing suppliers that are closer to their operations. Nearshoring brings production closer to its endpoint to help mitigate delays and other risks. It also creates a supply chain safety net moving forward.

A December 2022 Capterra article pointed out that 88% of U.S. small and midsize supply chain professionals have plans to switch at least some of their suppliers to ones closer to the U.S., with 45% planning to switch all of them.

Listen to our podcast on weighing nearshoring vs. offshoring vs. reshoring.

Pain Points for Manufacturers Relying on Offshore Supply Chains

In addition to the pandemic, several additional downsides to complete offshore supply chain reliance have emerged:

- Geopolitical issues throughout the world hamper sourcing and procurement.

- Existing trade tariffs along with the European Union’s upcoming “carbon tariff” – the Carbon Border Adjustment Mechanism (CBAM). Read how manufacturers are preparing for the EU CBAM.

- Material and shipping costs including higher fuel and raw materials prices.

- Labor shortages, impeding production and time to market.

- Environmental, social, and corporate governance (ESG) compliance, making monitoring of offshore fair labor and trade practices challenging.

- Potential financial and legal ramifications for not meeting regulatory requirements. The National Law Review noted that government regulators, investors, and customers are holding companies accountable for their public statements regarding climate risk and other ESG factors.

As a result, U.S. manufacturers have taken a closer look at nearshoring in Mexico, Central America, and even parts of Europe to improve supply chain risk management.

Advantages of Nearshoring

As a result, U.S. manufacturers have taken a closer look at nearshoring in Mexico, Central America, and even parts of Europe to improve supply chain risk management.

Although U.S. and Western European labor tends to be more costly, advanced robotics and automation are compensating for some of these expenses. Deloitte’s The Future of Freight: Transforming the Movement of Goods cited that nearshoring contributed to shortening supply chains. Examine several key advantages of nearshoring:

- Greater transparency and free trade agreements. The U.S. has free trade agreements with 20 countries covered by North American Free Trade Agreement (NAFTA) and other legislation. Such agreements provide greater transparency and facilitate the navigation of regulations and import requirements. Additionally, labor, safety, and health laws are more closely aligned among trading partners to improve oversight across the supply chain.

- More expedient crisis control and greater resilience. When an issue does arise, it can be remediated more quickly since suppliers are closer and often in a similar time zone. A more proactive, hands-on approach saves time and money.

- Financial enticements. Suppliers closer to production often mean more incentives. Mexico, Canada, and Central America are attractive options for U.S.-based businesses, offering competitive labor rates and faster delivery times that save money.

- Fewer shipping delays and bottlenecks. Borders are far easier to cross with neighboring countries than across oceans. During the pandemic, approximately 300,000 workers were stuck at sea for months due to Covid-19 restrictions and labor shortages at the docks.

- Smaller cultural divide. Shared or similar cultures are more likely to nearshore. Communication gaps are narrower or non-existent. Work norms and holidays tend to be similar, reducing response time lags and shipping delays. More closely aligned legislation and regulatory requirements facilitate a more seamless supply chain efficiency.

Discover how nearshoring factors into your sustainable product design and manufacturing strategies.

aPriori Can Facilitate Nearshoring

To ensure maximum impact for your supply chain risk management, a manufacturing insights solution that provides detailed, real-time supplier data to work in tandem with your nearshoring program.

- Design with the supply chain in mind. aPriori’s manufacturing insights can mitigate supply chain issues via design and the manufacturing process. If a part is unavailable, aPriori’s solution allows design engineers to adjust the design early in product development and/or identify closer suppliers to accelerate time to market.

- Utilize should cost analysis. With a should cost analysis tool like aPriori’s, manufacturers can more accurately forecast/calculate product costs from suppliers. It also gives them greater negotiation leverage when considering suppliers closer to home.

- Rely on automation and robotics to offset labor shortages and accelerate time to market. Though nearshoring labor costs can be more expensive, automation and robotics can offset them. Rudimentary tasks can be automated, requiring fewer workers.

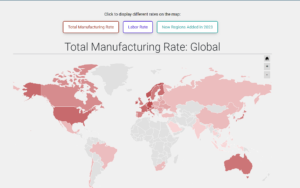

- Comparison shop sourcing and procurement. aPriori’s Regional Data Libraries can help manufacturers with sourcing and nearshoring decisions faster. Explore our interactive map with 87 regions to understand labor, total manufacturing rates, and more, drilling down in each region.

- Improve communication and collaboration between suppliers and internal teams. With aPriori’s insights, manufacturers can get more detailed, up-to-date supplier feedback. As a result, they can align with the most appropriate suppliers, strengthen relations, and identify opportunities for renegotiation.

- Weigh cost vs carbon to see where you can lower your CO2 footprint. aPriori’s solution allows manufacturers to explore the advantages of working with suppliers closer to them to reduce CO2.

- Compensate for delay hiccups with faster quoting times. Utilizing aPriori’s digital factories allows manufacturers to quickly simulate manufacturing to match their unique capabilities and cost structure. See how one aPriori customer improved their RFQ win rate from 15% to 68%.

- Leverage digital factories to determine nearshoring feasibility. Duplicate a factory in another country to test the validity of it. Explore the differences in supplier availability and cost. It can ensure you have a backup plan should your main suppliers experience disruptions.

Determine if nearshoring is right for you. Watch our video to explore various regions and prices with our Regional Data Libraries.

Supply Chain Risk Management: A Balancing Act

There are no hard and fast rules to nearshoring. The prudent approach is moving operations closer to home for greater resilience while leaving offshore supplier options open. Find the sweet spot between the two, and your supply chain risk management will be an unstoppable force regardless of the next curveball thrown your way.

Transform Your Sourcing Program

See How EV OEMs Are Using Digital Twins In This Effort