Key Takeaways:

- PTC and aPriori provide an integrated solution to elevate product sustainability

- Manufacturers are using environmental sustainability to capitalize on new market opportunities

The Full Article:

Manufacturers continue to address how to incorporate environmental sustainability into their strategic initiatives to address customer demands, navigate regulatory requirements, and meet their corporate sustainability requirements to help address climate change.

To help meet the United Nation’s (UN) goal to reduce global carbon emissions (CO2e), an array of measures that manufacturers need to address include:

- The European Union’s (EU) “Carbon Tariff”: In October 2023, the EU’s Carbon Border Adjustment Mechanism (CBAM) begins to take effect. The EU tariff could increase some material import costs by 30%. Read our blog for practical steps to prepare for CBAM.

- Sustainability Reporting Requirements: The EU, England, and other government entities are implementing mandated sustainability reporting for corporations. Public companies that meet EU disclosure thresholds, for example, are required to institute internal controls to identify and report on climate-related risks that may have a material impact. Learn more about addressing EU Taxonomy sustainable reporting requirements.

- Industry-specific Mandates: Building construction and other industries are implementing their own sustainability standards (e.g., LEED certification in the US and the EU’s CSN EN Standards). In the EU, for example, HVAC systems and other building products are required to meet sustainability benchmarks based on Environmental Product Declarations (EPDs).

Drive Product Sustainability with PTC & aPriori

To help manufacturers capitalize on product sustainability opportunities, PTC and aPriori are supporting manufacturers’ environmental sustainability goals. These solutions enable designers to review designs in CAD and PLM, and generate reports for part costs, manufacturability, and environmental footprint. Specifically, PTC and aPriori are increasing interoperability between Windchill and aPriori’s aP Pro, aP Design, and aP Generate software. (There is already deep integration with aPriori and PTC Creo.)

aPriori can automatically analyze Creo design updates in Windchill. If changes are required, aPriori’s software generates recommended improvements for cost, sustainability, and manufacturability for product designers. Product design teams can review and implement the changes early during the development – and eliminate late-stage change orders to reduce a product’s cost or carbon footprint.

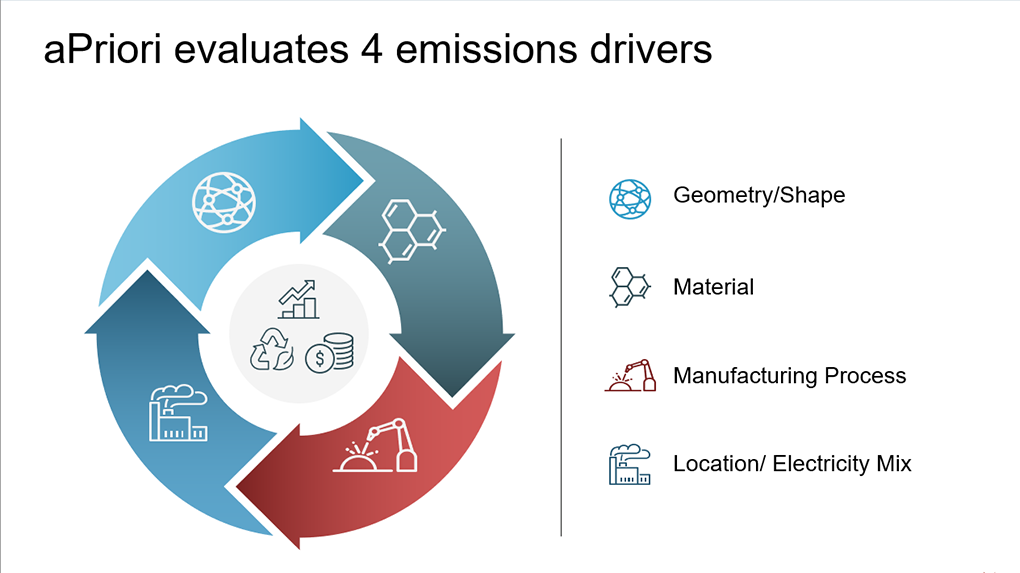

aPriori Sustainability Insights evaluates greenhouse gas (GHG) emissions at the product level, from cradle to gate, including Scope 3 (i.e., throughout the supply chain). Accordingly, organizations gain fast, transparent CO2e breakdowns to compare alternate product geometries/shapes, raw materials, manufacturing processes, and suppliers/locations.

aPriori also estimates the “clean energy mix” for production by region. Leveraging ecoinvent’s life cycle assessment (LCA) database as a foundation, aPriori’s Digital Factories calculate both material and electricity carbon emissions factors for each part. In addition to providing projected factory CO2e data, aPriori Regional Data Libraries (RDLs) provide manufacturers with variable material and supplier production costs across 87 regions globally.

Manufacturers can use aPriori’s new sustainability software without additional user inputs, applications, or integrations. aPriori’s precise CO2e insights extend the platform’s existing powerful capabilities. This allows companies to use aPriori Sustainability Insights effortlessly to bring their high-quality, low-carbon, cost-effective innovations to market faster to ensure profitability.

Watch this webinar to learn how aPriori helps to reduce a product manufacturer’s carbon footprint.

How It Works: Using aPriori Sustainability Insights

aPriori applies its multiple digital twins (product, process, and digital factory twins) to generate the following product carbon footprint calculations automatically:

- Material CO2 aPriori captures all GHG emissions ranging from raw material extraction to material utilization.

- Process CO2 The aPriori platform leverages energy use, cycle time, and electricity CO2e mix factors to calculate process CO2e, including overhead.

- Total CO2 aPriori adds the material CO2e and the process CO2e to calculate the total CO2e. Manufacturing companies can then use the total CO2e to identify the largest carbon offenders and focus on mitigation.

Advantages of a PTC-aPriori Product Sustainability Solution

Sustainability is integral to manufacturing today. The combined PTC and aPriori solution includes sustainability features and capabilities that are essential.

- Capitalize on your PLM Investment: Automation and collaboration are central to accelerating product development while also achieving cost, performance, and sustainability targets. aPriori integrates with PTC Windchill to generate automated insights and alerts at scale to identify potential issues, such as design risks and cost outliers.

- Use an Integrated Solution: Use a solution right out of the box that covers sustainability, cost, and manufacturability. And have the flexibility to configure it to mirror specific factories. aPriori enables you to run trade-off analyses – comparing CO₂e and cost options – to identify the areas that are the biggest contributors to them.

- Gain Precision Through Detailed Manufacturing Simulation: A granular understanding of cost, carbon, and manufacturability contributors is essential to making effective decisions. It should be fully automated to calculate CO₂e from 3D CAD data without manual setup of factory routing or manual data entry. And calculations should be consistent and highly repeatable with documented assumptions to support transparent and traceable reporting.

- Apply Actionable Recommendations in Real Time: What good is feedback without actionable recommendations or practical alternatives? Your solution should not just be a yardstick for sustainability. It should provide sustainable recommendations for the appropriate materials and manufacturing processes as well as the best locations to source and produce materials and parts, respectively. Whether it is designing (i.e.-shape, weight, material trade-offs, reuse opportunities, etc.), manufacturing (i.e.-baselining, lower impact process routing, etc.,) or sourcing (i.e.-make vs. buy, material sourcing, etc.), an impactful manufacturing insights tool will offer these capabilities, which in turn will better support sustainability management.

Sustainable Design: A Catalyst for Growth

A sustainable product strategy can be profitable and also position a manufacturer for long-term growth. However, it takes the right strategy and the right manufacturing insights to evaluate profitability, sustainability, and manufacturability simultaneously. Importantly, sustainable design engineering incorporates the entire product life cycle — including design, procurement, production, and end of life — to minimize waste as part of the circular economy model for eco-friendly products.

The PTC/aPriori product sustainability solution can help manufacturers accelerate this process today by capitalizing on their existing PLM investments to reduce their carbon footprint – and evaluate profitability, sustainability, and manufacturability holistically. This insight, in turn, can help manufacturers reduce their environmental impact and gain a competitive edge.

Frost & Sullivan Names aPriori the Digital Manufacturing Solutions Leader

Read the report to get the full story.