Expand Your Sphere of Influence by Extending Your Cost Engineering Expertise to the Entire Product Team

It’s a fact. No matter what industry you are in, or what company you work for, cost engineering teams are always understaffed and underfunded. We’ve seen scenarios at major global manufacturers where there are thousands of product designers and a team of 20-30 cost engineers trying mightily to keep up with the flow of new product designs. We get it, you need help.

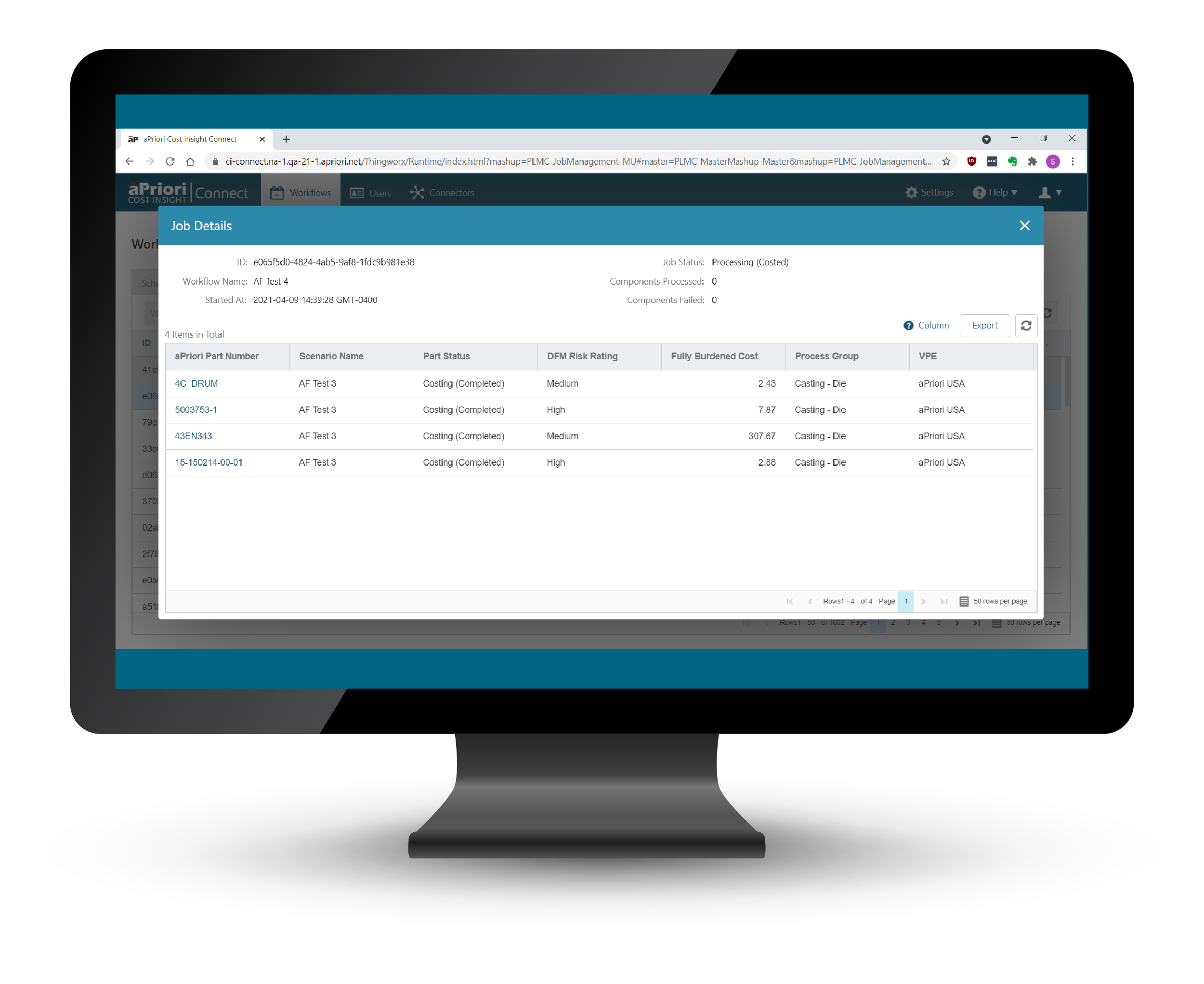

Put simply, automation is the answer to your problems. Instead of evaluating one part at a time, what if you could analyze hundreds, even thousands of new part designs at once. Set up a batch run, go home, eat your dinner, go to bed, come back the next morning and your results are waiting for you. Sounds too good to be true, right? Well, it’s not.

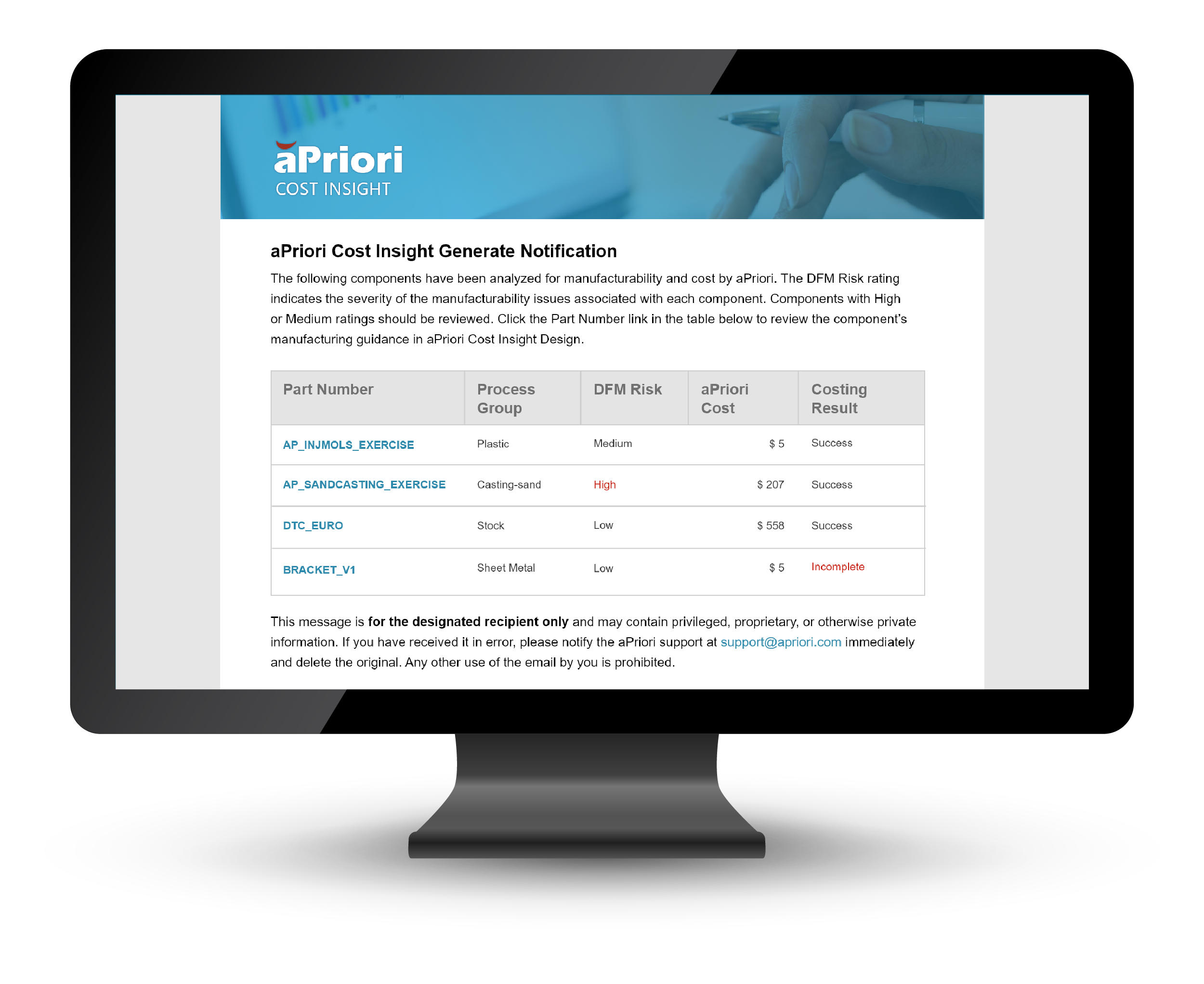

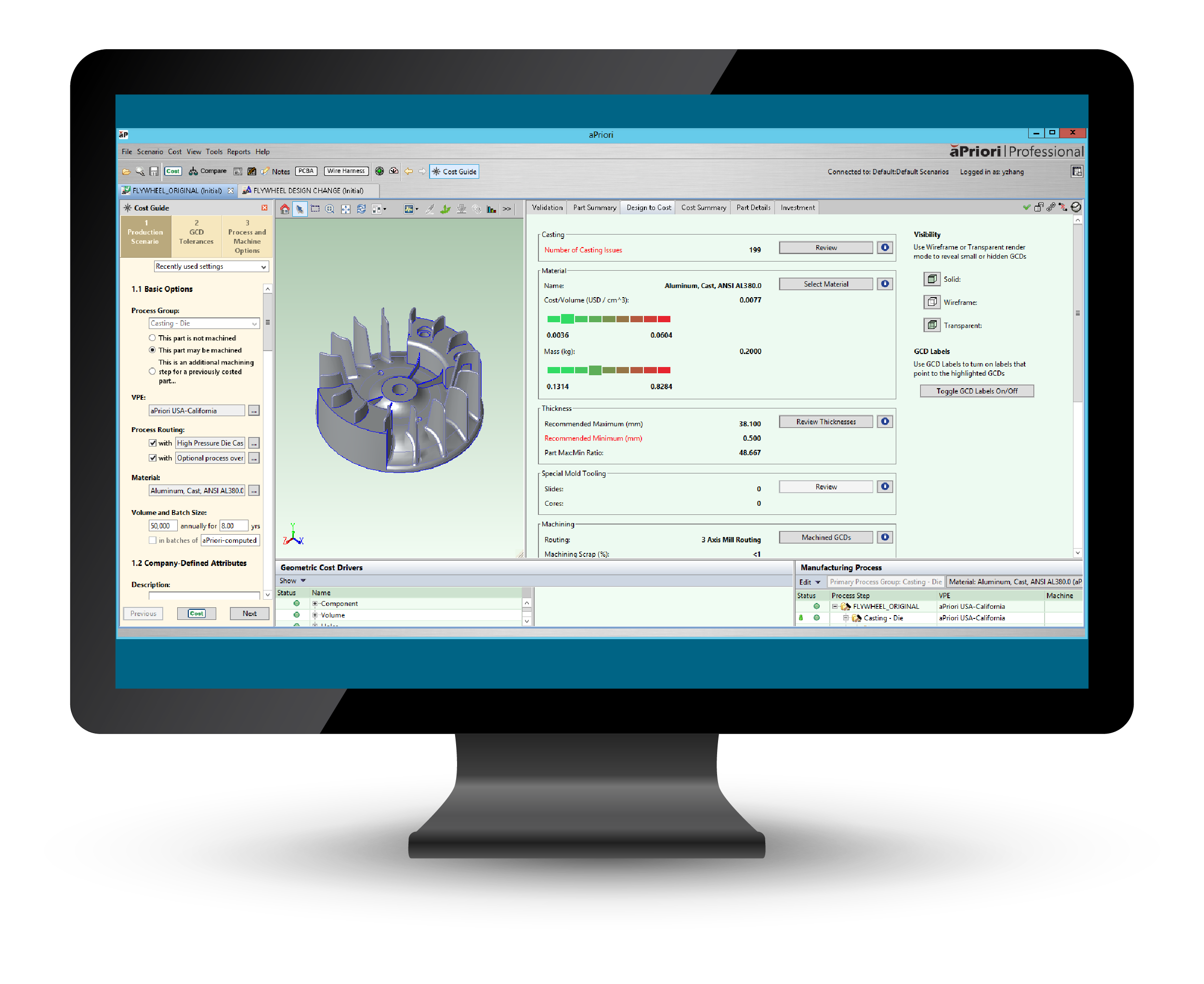

And, that’s not the only benefit digital manufacturing simulation can bring to cost engineers; whether you are on a large team, or if you are part of a two-person team at a machining shop trying to keep up with new quote requests from your customers. For years and years, the manufacturing and cost analysis process has consisted of designers and engineering departments throwing a new design over the wall with only days left until product launch, and now you are under the gun to analyze a complex design with not nearly enough time to get it done. What if you could project your cost expertise across the company so that the designers and engineers – the folks responsible for creating cost – had the capability to a first-order analysis of manufacturability and eliminate some of the more obvious problems before they ever got to you. Again, impossible you say? With digital manufacturing simulation software this is a reality that you can achieve.

Your underfunded and understaffed cost departments consistently try to keep pace with product designers that are 10x or more the size of their department. And while expectations to reduce costs for the company increases, there is still a heavy reliance on outdated cost estimation technology and homegrown costing systems to meet growing demands. It’s about time cost engineering teams had a tool of their own.

Bring Your Cost Engineering Team Into the Future of Manufacturing

Your design and sourcing teams can benefit from the expertise that cost engineers bring to the table. As part of the software deployment team, you get to set the rules and constraints that will ensure high-quality design practices that eliminate obvious manufacturability errors that should never make it to the cost engineering team.

Here's how it works:

Seeing is Believing. Request a Demo.

We’ll show you exactly how aPriori works.aPriori Solutions for Cost Engineering

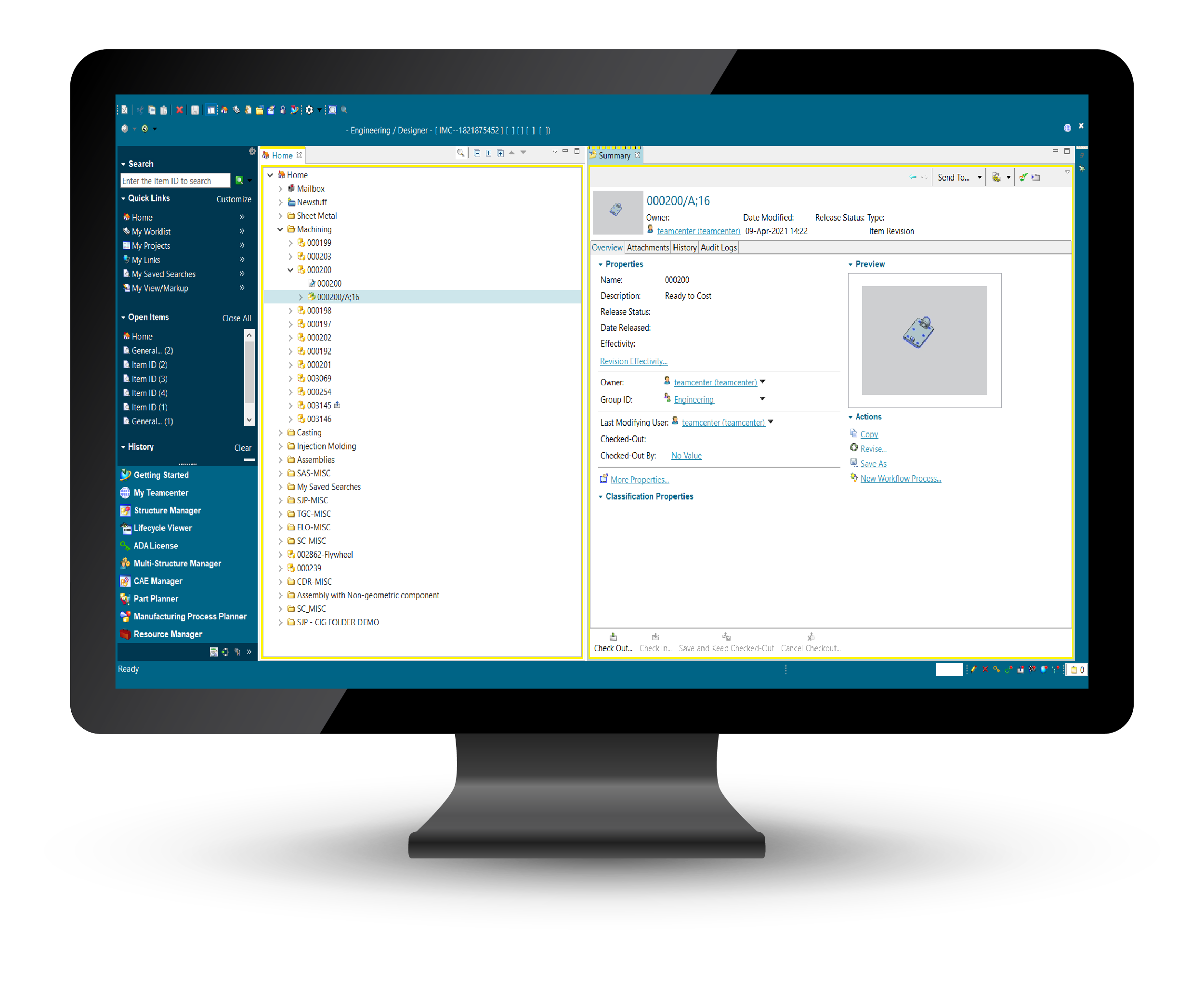

Connect aPriori to your PLM system for automated manufacturing simulation upon check-in of new or modified CAD designs.

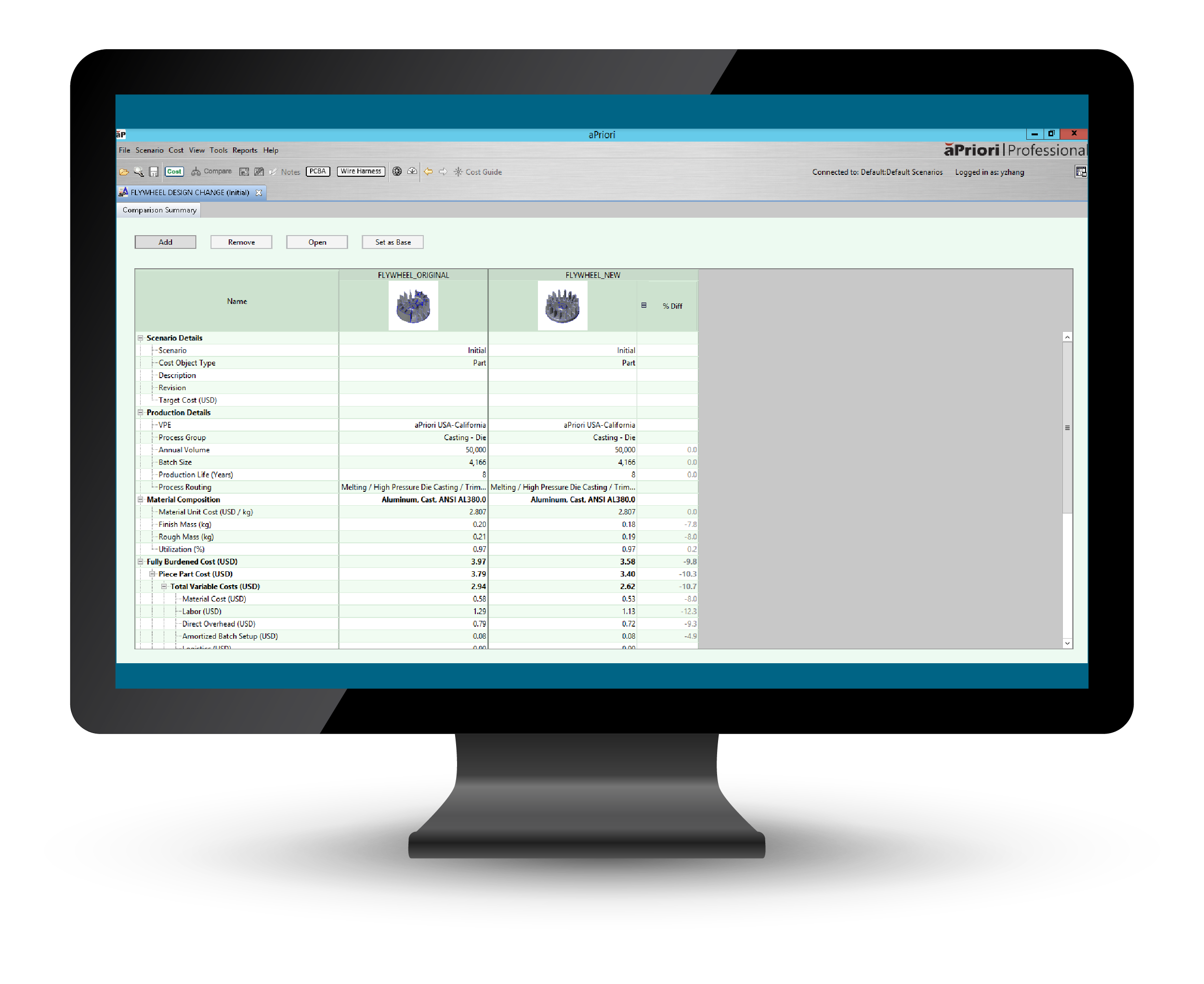

Collaborate with other cost engineers and align your design for manufacturability goals with the entire product lifecycle team: From project management to sourcing professionals.

Detailed reports of cost data for your products. Create custom dashboards to consistently monitor new product initiatives against Design to Cost targets.