Greener Products Start With a Green Supply Chain

Key Takeaways:

- Manufacturers face increased pressure to measure and mitigate their supply chain emissions

- aPriori’s actionable sustainability insights streamline green supply chain management initiatives

The Full Article:

In today’s global landscape, manufacturers face unprecedented environmental challenges that impact their ability to innovate, compete, and remain profitable. Despite commitments to reach net zero, carbon emissions continue to rise, and so does the need for innovators to incorporate sustainability into their product development processes.

The green supply chain concept encourages innovators to make eco-friendly decisions throughout the product life cycle. Embracing supply chain sustainability allows companies to reduce negative environmental impacts, improve profitability, and preserve the planet for future generations.

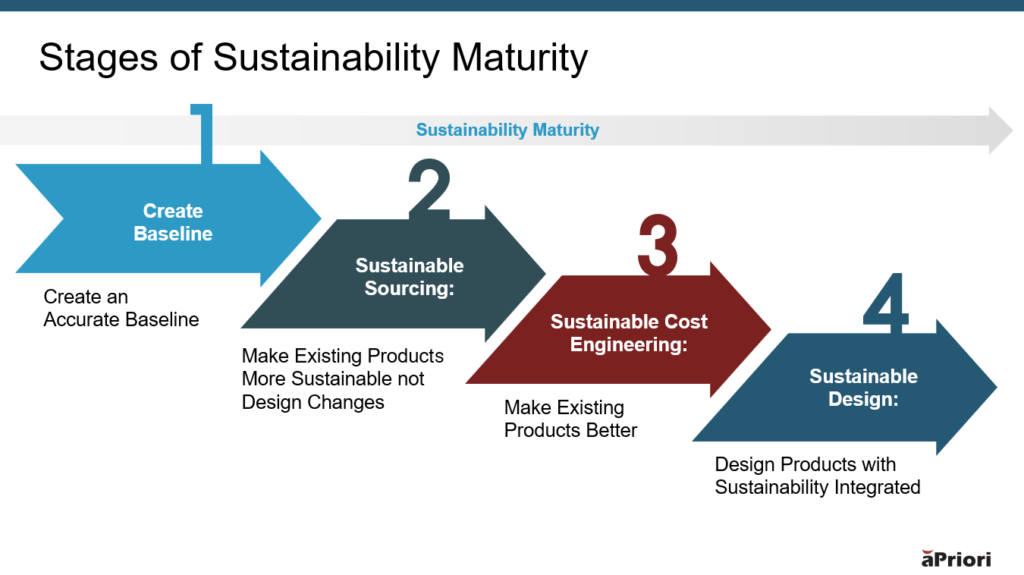

But how can manufacturers implement these sustainable decisions and track their progress while building on existing capabilities? We address the question by examining the four stages of a sustainability maturity model we developed based on discussions with manufacturing leaders.

What is the Sustainability Maturity Model?

The sustainability maturity model is a strategic roadmap for manufacturers to assess their current capabilities and the effectiveness of their green supply chain management initiatives. By monitoring their sustainability maturity performance, product teams can strategize, make informed investments, and strengthen their operations to advance through the stages.

According to Figure 1, product development teams can assess and pinpoint their position across four stages of sustainability maturity. These include:

- Stage 1: Creating Precise, Auditable Carbon Dioxide Equivalent (CO2e) Emissions Baselines

- Stage 2: Choosing Sustainable and Responsible Global Suppliers

- Stage 3: Optimizing Existing Product Innovations for Cost and Carbon

- Stage 4: Removing Embodied CO2e Through Superior Product Design

Below, we explain how aPriori enables innovators to succeed at all four stages of sustainability maturity to achieve a greener supply chain.

Stage 1: Creating Precise, Auditable CO2e Emissions Baselines

Creating an accurate carbon emissions baseline is the first step in achieving a sustainable and green supply chain. This baseline empowers sustainable manufacturers to measure and quantify the carbon footprint of their existing supply chain operations, enabling them to:

- Identify and focus on the areas with the highest cost and carbon reduction potential.

- Set realistic cost targets that guide and influence product teams’ supply chain decisions.

- Adhere to environmental, social, and governance (ESG) standards and regulations.

- Benchmark and compare their sustainability performance against industry competitors.

While companies recognize the importance of accurate baselines, they struggle to create them without a tool that provides early visibility into Scope 3 emissions. Precise and effective baselining requires an understanding of the following emission scopes defined by the Greenhouse Gas Protocol (GHG Protocol):

- Scope 1 addresses emissions from owned or controlled sources.

- Scope 2 includes indirect emissions from purchased energy generated.

- Scope 3 measures all the upstream and downstream emissions.

Tools like lifecycle assessment (LCA) systems can evaluate a product’s overall environmental impact, from raw material extraction and transportation to end-of-life disposal. However, these tools do not provide access to real-time sustainability data for teams to make early and influential design-stage decisions.

aPriori’s automated sustainability insights solution closes the gap by integrating data from ecoinvent, a leading third-party LCA and inventory database tool. aPriori utilizes ecoinvent’s reputable database to quickly establish environmental baselines and evaluate greenhouse gas (GHG) emissions at the product level.

With automated and more precise baselining, teams can quickly move to the second phase of sustainability maturity: evaluating and selecting sustainable suppliers.

Stage 2: Choosing Sustainable and Responsible Global Suppliers

The second stage of sustainability maturity is evaluating and selecting suppliers based on their local electricity mix, material supply, and processes (Scope 3). Product teams aim to enhance the sustainability of existing innovations through informed supplier selections instead of resorting to costly design or material changes.

Sustainable sourcing offers the most straightforward approach to reducing CO2e by minimizing the need for extensive changes. However, it is difficult for product teams to capitalize on this opportunity without a dedicated and standardized tool such as aPriori.

aPriori provides manufacturers with complete visibility into the sustainability of their supply chain, empowering them to make data-driven sourcing decisions. By utilizing aPriori for sustainable sourcing, companies can:

- Explore various “what-if” scenarios (regions, routings, materials, volumes/batches, suppliers, make vs. buy).

- Reduce iterations and negotiation by digitally connecting buyers and suppliers.

- Fill skills gaps with exposure to granular, actionable, real-world sourcing data.

- Identify sustainable procurement strategies to support internal ESG goals and initiatives.

Stage 3: Optimizing Existing Product Innovations for Cost and Carbon

As a crucial third step, the path toward greener products involves optimizing existing product innovations. Product teams can consider alternative materials with lower carbon and higher recycled content during this stage. They can also make processes more efficient and utilize renewable energy sources to improve cost and environmental sustainability.

The objective is to minimize cost overruns and release products at target costs to maintain profitability and competitive advantage. However, this is difficult to achieve when cost engineering teams are limited to conventional, labor-intensive costing tools like manual spreadsheets. And the complexity of this challenge heightens when the situation extends to CO2e emissions. This is because spreadsheet-based solutions cannot:

- Evaluate the complex interrelationships between direct and secondary cost & carbon drivers in real time.

- Accurately manage the vast array of cost & carbon variables in an ever-changing global supply chain.

- Identify and capitalize on cost & CO2e reduction opportunities early in the product design process.

aPriori provides a precise, real-world product cost optimization solution to make highly informed and effective manufacturing decisions. aPriori’s automation-driven platform can simulate production based on product design (geometry), manufacturing overhead costs, direct labor hours, machine hours, and more.

Additionally, aPriori enables companies to navigate and manage rising material costs, inflationary pressures, and other external risks to build cost-effective products. aPriori also automatically notifies and provides actionable feedback to design, manufacturing, and sourcing teams when products exceed cost thresholds. This facilitates seamless collaboration among product development teams, enabling them to eliminate cost drivers early and maintain corporate profit margins proactively.

Stage 4: Removing Embodied CO2e Through Superior Product Design

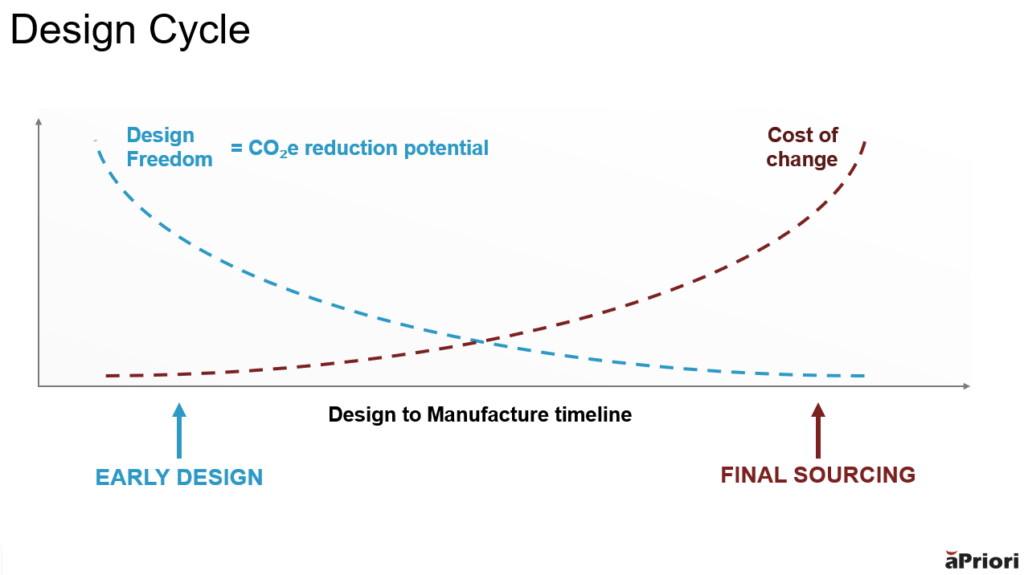

The final stage of sustainability maturity represents the most challenging path and the greatest opportunity for reducing GHG emissions. By using real-time CO2e feedback from the 3D CAD model, teams can proactively modify the design of a product to reduce its embodied carbon.

As depicted in Figure 2, aPriori allows teams to manage tradeoffs and balance product cost, carbon, and manufacturability at once. Carrier Corporation and other top manufacturers use aPriori to evaluate and identify cost-saving opportunities within their complex parts automatically. Carrier uncovered annual savings of $21 million with aPriori and deems the platform central to achieving its ambitious 2030 ESG goals.

Learn more: Read three case studies on balancing product CO2 and cost by evaluating options across manufacturing regions, processes, and materials.

Achieve Your Green Supply Chain Management Goals With aPriori

Advancing through the four stages of sustainability maturity indicates that companies are on the right path toward a green supply chain.

aPriori’s automated solution accelerates the process by providing actionable, real-world manufacturing insights that drive low-carbon and cost-effective decisions. The platform streamlines sustainable product innovation by allowing cross-functional project teams to:

- Go beyond the 3D CAD model. aPriori automatically extracts geometric data from 3D CAD models checked into existing product lifecycle management (PLM) systems. aPriori’s digital factories can be configured to simulate the real-world costs and environmental impacts of different raw materials, product designs, manufacturing processes, suppliers, and more.

- Centralize product data for rapid decision-making. With aPriori, cross-functional teams only use one source of truth to access product, material, and manufacturing process insights. Project stakeholders can collaborate more seamlessly and make rapid, data-driven decisions to bring their sustainable innovations to market faster.

- Gain actionable CO2e insights. Organizations can complement their existing LCA tools and build upon their “cradle-to-grave” product environmental impact reports with aPriori. aPriori’s sustainability insights equips teams with rapid “cradle-to-gate” carbon calculations early in the design phase. The platform calculates CO2e emissions by considering the rough mass, cycle time, and energy consumption utilized to produce parts or assemblies.

Despite evolving market conditions, aPriori enables innovators to maintain profitability, mitigate supply chain risks, and reduce their contributions to climate change.

Get aPriori's Exclusive Guide to Reducing Product Emissions