Carrier Streamlines Supplier Management With Digitalization

Key Takeaways:

- Carrier requires digitalization to drive innovation and remain industry competitive

- Carrier automates should cost analysis to streamline supplier management and capture savings

- Carrier’s look ahead: Using digitalization to achieve zero RFQ and 2030 sustainability goals

The Full Article:

Carrier Global Corporation is the industry leader in heating, ventilation, and air conditioning (HVAC), refrigeration, and fire security systems. The manufacturer generated $22.1 billion in sales in fiscal year 2023 across more than 80 industry-leading brands, including Carrier, NORESCO, and Automated Logic.

To remain industry competitive, the global manufacturing powerhouse needed to digitalize its labor-intensive should costing process to streamline supplier management. Digitalization will allow Carrier to increase its accuracy, efficiency, responsiveness, and speed to strengthen supplier relationships and reduce procurement risks.

Key Business Problem: Should Cost Modeling for Complex Parts

Carrier’s should cost team faced two challenges that hampered its ability to analyze and optimize product costs across 9,000 active patents. The manufacturer needed automation, speed, and cost estimation efficiency to quickly evaluate the expenses of various complex parts with different manufacturing processes.

The global manufacturer needed to address the following areas to optimize product cost and value and improve supplier relationship management:

Utilizing Manual Spreadsheets as a Primary Cost Estimation Tool

Before adopting aPriori, Carrier relied on manual time-consuming Excel spreadsheets to generate should cost estimates for many complex parts. Should cost projections determine a fair market price for components, which can be used to guide negotiations between suppliers and procurement teams.

Unfortunately, spreadsheets cannot provide granular, accurate, real-time estimates of how multifaceted production processes influence the total cost of a component. Additionally, manual should cost modeling tools make it impossible to evaluate the cost of many parts quickly and simultaneously.

“You shouldn’t have to do a manual should cost analysis on everything. It’s just impossible,” said Tristan Abend, Value Engineering Manager for Carrier. “We can try, but it’s just not going to work. It’s not a valuable sense of time. Because of that, you should use something less like a ‘sledgehammer’ and more like a ‘surgical scalpel’ and be able to go through an entire bill of materials.”

Receiving Constant Should Cost Requests From Engineering and Supply Chain

Carrier’s cost team is responsible for receiving and handling multiple should cost requests from global engineering and supply chain personnel. The company’s should cost team often had busy workspaces and ever-increasing project queues due to the volume of requests they received.

The should cost team needed an automation-driven digital manufacturing solution with quick, granular, and precise estimates to balance the requests. That is when the leading manufacturer identified aPriori as the right should cost modeling technology to overcome its current challenges.

Carrier Adopts aPriori to Streamline Its Should Cost Analysis Process

Carrier adopted aPriori’s automated should cost modeling solution to gain a more granular understanding of supplier costs for complex parts. Carrier’s current aPriori implementation has 125 users globally in cost, design, and value engineering, with plans to expand its user base this year.

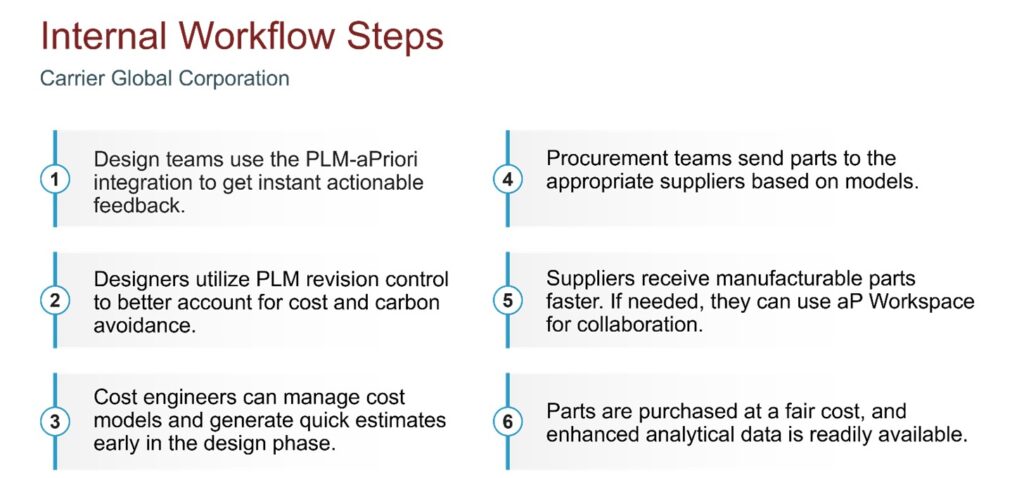

aPriori integrates seamlessly with Carrier’s product lifecycle management (PLM) software to analyze its diverse 3D CAD models automatically. aPriori threads three digital twins together—product, process, and factory twins—to unlock precise should cost and manufacturability insights.

Carrier utilizes nearly 90 digital factories in aPriori to make data-driven decisions based on real-world labor rates, material costs, and production processes. aPriori’s highly granular, transparent insights enable the manufacturer to meet its cost engineering targets faster and more efficiently.

The manufacturer also leverages aP Workspace, aPriori’s real-time collaboration tool, to centralize teams, manage tasks quickly, and make decisions confidently. With aP Workspace, relevant stakeholders can easily access critical data and collaborate seamlessly to produce high-quality, cost-effective innovations.

Carrier’s internal workflow steps when using aPriori are as follows:

Carrier Discovers $21 Million in Potential Value With aPriori

Carrier’s should cost team discovered $21 million in annual savings using aPriori’s effective manufacturing cost modeling software. These significant cost savings enable Carrier to invest in its business and empower more innovation across the product team.

Additionally, the global manufacturer uses aPriori to make early design-stage product iterations and validate overall cost and manufacturing feasibility.

Since implementing aPriori, Carrier has been able to advance the following initiatives:

- Improve Supplier Management and Strategic Sourcing. Carrier’s sourcing team uses aPriori’s real-world insights to identify viable global suppliers based on cost and lead times. Further, aPriori gives Carrier accurate estimates to initiate collaborative and fact-based supplier negotiations to achieve savings on various parts. aPriori also enables Carrier’s procurement team to send viable parts to suppliers more quickly with improved alignment in the supply chain.

- Accelerate Product Development and Eliminate Delays. aPriori provides early estimates to help Carrier meet its cost targets faster and avert costly end-stage engineering change orders (ECOs). With aPriori, Carrier’s product development team gains a quick and transparent collaboration tool that helps decrease time to market (TTM). This gives the company more time for innovation and product design generation. Additionally, Carrier leverages aPriori’s detailed analytics to quickly adapt to ever-changing market conditions and make highly informed data-driven business decisions.

Carrier’s Road Ahead: Zero-RFQ and Environmental Goals

The leading manufacturer has two near-future goals that aPriori can help realize. These goals include the following:

1. Achieving Zero RFQ

Carrier plans to use aPriori’s configurable digital factories to achieve zero RFQ time with new or strategic suppliers. Once a digital factory is specified to a particular supplier, aPriori manufacturing simulation can help Carrier achieve a quick, accurate quote for new RFQs. This eliminates delays in the sourcing and procurement process.

2. Improving Sustainability

Alongside zero RFQ, Carrier has ambitious 2030 environmental, social, and governance (ESG) goals, such as:

- Reducing customers’ carbon footprint by more than one gigaton.

- Achieving carbon-neutral operations across the organization.

- Investing over $2 billion to develop solutions incorporating sustainable design principles and reducing life cycle impacts.

Abend believes that aPriori is critical and central for Carrier in achieving its 2030 ESG goals. “aPriori is one of the key players in our sustainability strategy going forward,” said Abend. “The platform will enable us to assess each design revision in real time and determine whether product cost and carbon improve. And all aPriori insights and metrics are seamlessly fed to our PLM system.”

Carrier and other global manufacturing powerhouses rely on aPriori to design quality, cost-effective products while improving supplier management and negotiation. With aPriori, companies can gain a competitive advantage and bring their innovations to market faster.

Business Transformation Through aPriori

Learn how Carrier has achieved $21 million in potential value with aPriori automated cost analysis.