What’s New in aP Design: Thickness Visualization & Flow Appraisals

We’re thrilled to announce two powerful new features in aP Design, designed to give manufacturers and design engineers unprecedented insights early in the product development lifecycle: Thickness Visualization and Flow Appraisals.

These innovations, available to customers on July 15, empower you to identify potential manufacturing issues and optimize your designs for cost, CO₂e emissions, and manufacturability, all while saving critical time and resources.

See Your Design’s Core: Thickness Visualization

Understanding the thickness of your component is crucial yet often overlooked until later stages. With aP Design’s new Component Thickness Visualization, you can now instantly see a visual representation of your design’s thick and thin areas.

What does this mean for you?

- Early Problem Identification: Quickly pinpoint areas where excessive thickness could lead to material waste, longer cycle times, or increased cooling requirements. Conversely, identify thin sections that might be prone to weakness or difficult to fill during molding.

- Manufacturing Process Feasibility: Consistent and appropriate thickness is key for processes like injection molding, casting, or stamping. This visualization helps you understand if your design’s thickness variations are suitable for your chosen manufacturing method or if they might introduce issues like warpage, sink marks, or incomplete fills, often referred to as a “short shot”.

- Optimized Material Usage: By highlighting areas with thick sections of material, you can make informed decisions to reduce part weight and material costs, directly impacting your product’s overall cost and sustainability.

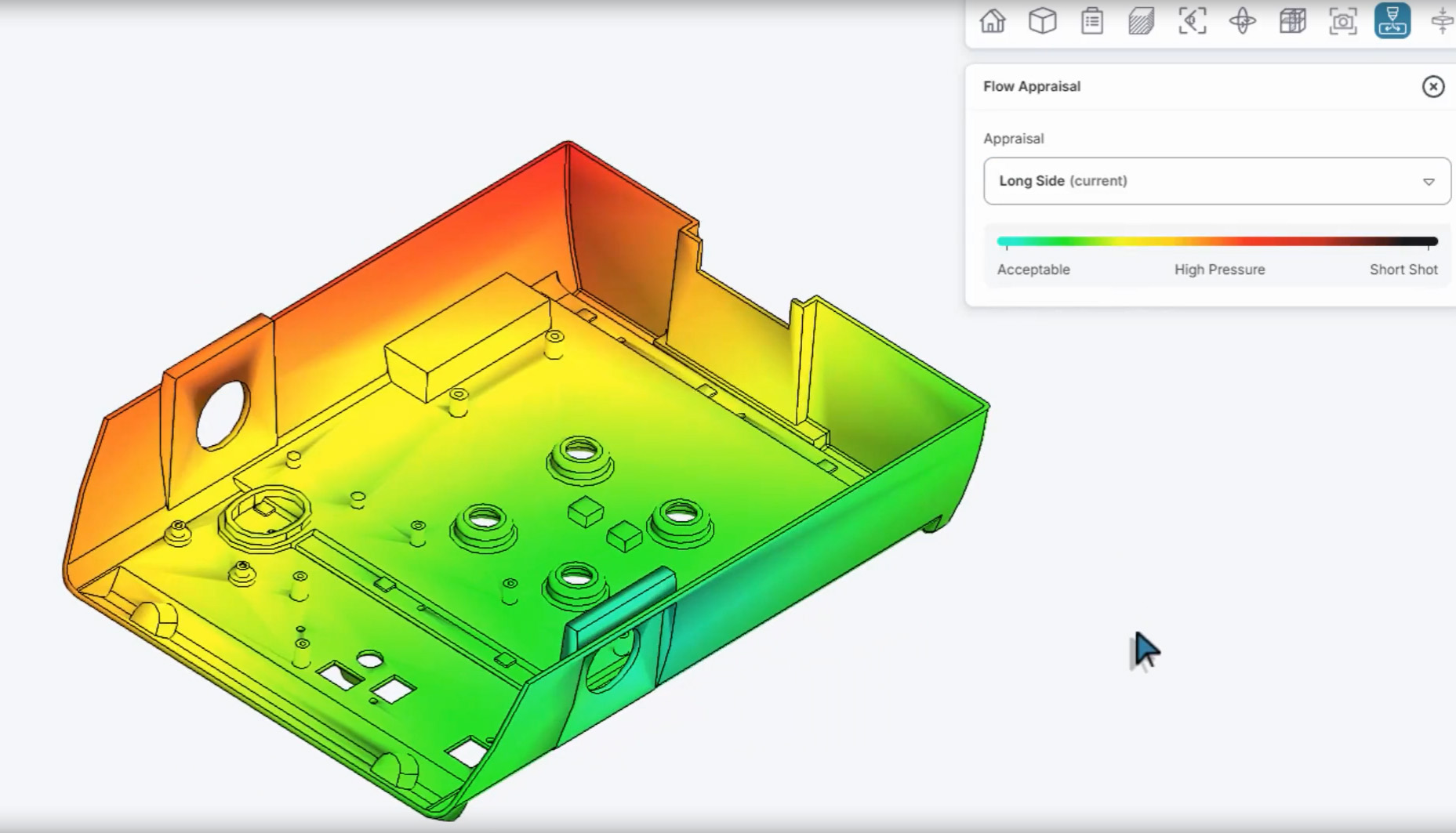

Real-time Insights: Introducing Flow Appraisals

Imagine getting crucial feedback on how your design will fill during a manufacturing process – without adding a second to your analysis time. That’s precisely what our new Flow Appraisals feature delivers.

Think of it as a “mold flow fill analysis lite” that seamlessly integrates with aP Design’s core capabilities. While traditional mold flow analyses can be time-consuming and require specialized expertise, Flow Appraisals provide instant feedback on potential flow issues as part of your existing cost, CO₂e, and manufacturability analysis.

The Benefits for Manufacturers and Design Engineers are Immense:

- Pre-empting Manufacturing Issues: Identify potential problems like short shots, weld lines, air traps, or unbalanced filling before you ever commit to tooling. Before you even commit to a detailed mold fill and/or pack analysis. This early detection can save enormous amounts of time and money associated with rework and mold modifications.

- Accelerated Design Iteration: Get immediate feedback on design changes and their impact on material flow. This enables rapid iteration and optimization, allowing you to refine your designs much faster.

- Democratized Flow Analysis: You no longer need to be a simulation expert, or request help from one, to gain valuable insights into material flow. Flow Appraisals make this critical information accessible to every design engineer, empowering them to make better decisions from the outset.

- No Time Added, All the Value: The most remarkable aspect is probably the fact that Flow Appraisals are delivered in seconds, alongside your existing aPriori analyses. This means you gain vital manufacturing insights without any additional time commitment, ensuring your design process remains agile and efficient.

- Reduced Risk and Cost: By catching potential flow issues early, you significantly reduce the risk of costly production delays, tooling rework, and scrap material.

The Power of Early Feedback

Both Component Thickness Visualization and Flow Appraisals underscore aPriori’s commitment to providing actionable insights at the earliest stages of design. By integrating these powerful tools into aP Design, we’re enabling you to:

- Design for Manufacturability (DFM) from Day One: Proactively address potential manufacturing challenges, leading to smoother production and higher quality products.

- Optimize for Sustainability: Reduce material waste and energy consumption by designing more efficiently.

- Accelerate Time to Market: Streamline your design and development process by minimizing costly iterations and delays.

- Gain a Competitive Edge: Bring innovative, high-quality products to market faster and more efficiently.

We’re confident that these new features will transform the way you approach product design and development. Login to aP Design today and experience the future of early-stage manufacturing feedback, or as we call it, Quantified Design Guidance.

Watch the video of this amazing new technology!

Component Thickness Visualization and Flow Appraisals