How to Use Gen AI to Accelerate Product Design from Months to Minutes

Key Takeaways:

- Manufacturers are beginning to harness Gen AI for product development – including Eaton, which is cutting product design times by nearly 90%

- Companies that use actual historical product data and simulated insights to train generative AI models can unlock new levels of product innovation rapidly for a competitive advantage

The Full Article:

Is your company built to last? Surprisingly, 45% of CEOs surveyed doubt their business will survive the next decade without significant transformation. This high level of uncertainty is likely fueling the rush to adopt artificial intelligence (AI).

Applying AI to product design can have a positive ripple effect across the entire product development lifecycle. Manufacturers can apply generative AI (Gen AI) to develop new products at lightning speed. They can also optimize high-fidelity AI designs for cost, carbon, specific manufacturing processes, and even specific factory capabilities.

Most AI initiatives are in the planning or pilot phases – McKinsey reports that only 11% of companies surveyed have adopted Gen AI at scale. Companies are investing significantly in AI, and missteps at this stage could be costly and leave manufacturers further behind their competitors.

To help manufacturers navigate these challenges, we’ve outlined the keys to harnessing Gen AI for product development:

- Gen AI defined

- High-quality data is the foundation for AI

- How Eaton cut product design time by nearly 90%

- Guidelines for your Gen AI journey

1) Generative AI (Gen AI) Defined

Generative AI represents a new frontier in AI (ChatGPT may be the most well-known example). Traditional AI, also known as Deterministic AI, applies pre-programmed rules and algorithms to make decisions. Traditional AI systems solve well-defined problems, such as determining the most effective manufacturing process based on the properties of a specific part. Traditional AI examples include expert systems, decision trees, and natural language processing (NLPs), which are used in search engines, chatbots, and more.

Instead of using predetermined rules, Gen AI identifies data patterns to create new, unique content. This requires accurate data, machine learning (ML) for powerful analysis, and large language models (LLMs) to process and generate information across multiple formats, including text, images, and video.

2) High-Quality Data Is the Foundation for AI Solutions

Financial services, automotive, and other industries are awash in data because different industry sub-segments—such as consumer banking and asset management – can use similar data sets to create AI models for automated customer service and other applications. But that scale doesn’t apply to manufacturing because many sectors have different operating models (think high-volume consumer electronics manufacturing vs. low-volume products for aerospace or other highly regulated industries).

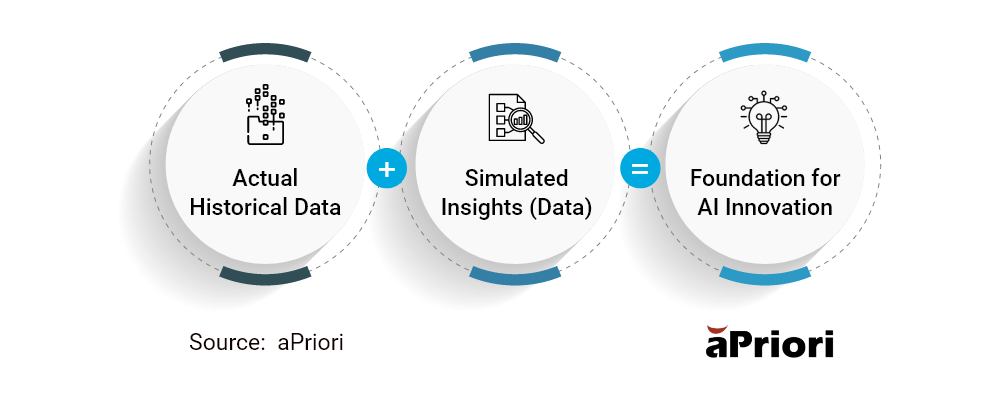

To compensate, manufacturers are combining actual historical product data and simulated insights to provide the data volume and quality required to make informed decisions.

How to Capitalize on Actual Historical Information and Simulated Design Data

A manufacturer’s actual historical data can include design files of its popular products, a list of its highest-margin products, product costs, production volumes, and preferred supplier information. It can also feature detailed performance data regarding company-owned factories and/or production lines.

However, analyzing a manufacturer’s actual historical data doesn’t typically help to identify areas for cost or time savings. For example, how do manufacturers know if they’re overpaying for a component if they only have quote and payment information?

To gain these types of insights, manufacturers rely on simulation and modeling to identify opportunities for improvement across the organization—including design for manufacturing (DFM), cost modeling, sustainability insights, and structural performance (FEA analysis). These simulation applications provide additional analysis and guidance to optimize myriad variables – and uncover new opportunities based on simulated changes to designs, raw materials, manufacturing processes, and more.

Integration across applications and platforms is central to harnessing all manufacturing information effectively. With complete control over product data, manufacturers can instantly adjust overhead rates for a plant in Taiwan or update raw material cost data to reflect inflationary pressures.

Manufacturers who understand why there are discrepancies between actual historical data and insights from simulation applications can use this knowledge to build precise AI models based on the most accurate information and establish parameters from multiple types of data.

3) How Eaton Cut Product Design Time by Nearly 90%

Eaton is a $23 billion intelligent power management solutions provider for industrial and manufacturing industries. Customers regularly require customized Eaton components/products for their new product development initiatives – ranging from passenger car valve stems to lighting fixtures.

Due to technical complexity, it can take Eaton months to complete a manual product design. For example, a lighting fixture design can require input from thermal, electrical, mechanical, optical, and manufacturing engineering.

“Eaton’s vision is to take our traditional design processes from months to minutes,” said Uyiosa Abusomwan, senior global technology manager of Digital Design and Engineering at Eaton.

Eaton’s Gen AI capability is built on a robust set of actual historical product design data and insights from the company’s simulation software portfolio – including aPriori for cost modeling, DFM, and sourcing. Eaton combines this information to create detailed model-based design specifications and properties to support its Gen AI development.

With Gen AI, Eaton runs thousands of design iterations in minutes (or less) and proposes the top-five prototypes / generative designs. Once the designs are fed through a high-fidelity simulation, Eaton’s digital design and engineering team conducts a detailed review. This workflow empowers the Eaton engineering team to review AI outputs for product validation and quality control, and streamline decision-making.

Result: Eaton Cuts New Product Design from Months to Minutes

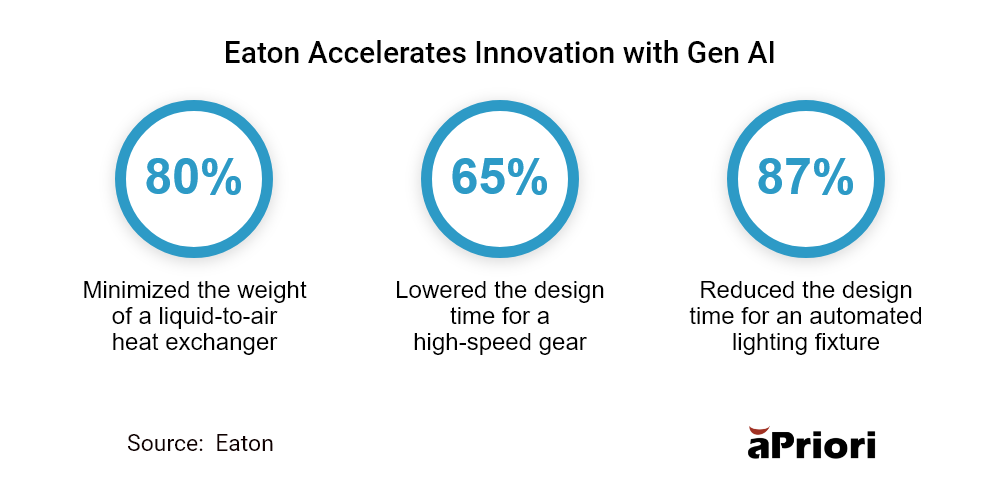

Eaton’s impressive results from its high-fidelity Gen AI initiative include:

- Minimizing the weight of a liquid-to-air heat exchanger by 80%

- Lowering the design time for a high-speed gear by 65%

- Reducing the design time for an automated lighting fixture by 87%

Eaton’s gen AI capabilities support the company’s goal to scale new product development and accelerate time-to-market to address customer needs. The technology could also support the company’s goal to become carbon-neutral by 2030.

4) Guidelines for Your Gen AI Journey

Establish and Scale Your Use Case: Does your Gen AI strategy incorporate criteria such as a product’s carbon footprint? The EU’s CBAM “Carbon Tax” and other sustainability mandates can influence where and how products are sourced and manufactured. And can your Gen AI provide complex analysis and recommendations based on multiple factors (for example, DFM, cost, carbon impact, materials, manufacturing location, etc.)? aPriori’s simulated manufacturing insights simultaneously evaluate product design cost, carbon, and DFM. Manufacturers that use actual historical product data and simulated insights to train generative AI models can unlock new levels of product innovation, speed, and competitiveness.

Weigh Data Quality Accordingly: Organizations are assigning value to content sources to help AI models weigh the types of data analyzed. Simulated product manufacturing insights have a high authority because companies use this data to simulate designs across multiple parameters – including design requirements (tolerances, etc.), cost vs. carbon trade-offs, alternative materials, different manufacturing processes, etc. AI models can use simulated product insights as training data to expand the breadth and depth of potential design options. Without this added dimension of data, the Gen AI outputs may be narrower in scope, less accurate, or even “hallucinate” (confabulate).

Protect Your Intellectual Property (IP): Cybersecurity risks aside, there are two often overlooked ways to safeguard a manufacturer’s product designs and other IP. Open/public Gen AI applications from OpenAI, Google, and others use LLMs and ML to continually “learn” and refine their responses to questions. So, proprietary information that employees share while using a public LLM could be used to train the tool – and then shared with other Gen AI users as part of future responses (potentially even competitors that use the same tool).

Additionally, applications promoting Gen AI capabilities could also use a company’s proprietary product designs or other data to refine its responses. Importantly, Traditional AI systems from aPriori and others don’t automatically learn from data. Because they use predefined rules to operate, Traditional AI doesn’t change or create rules automatically. Instead, Traditional AI data scientists/teams design and test new rules to ensure high fidelity before launching updates. Importantly, aPriori does not store customer data in its Traditional AI system (AI Rule Engine).

Take the Next Step In Your Gen AI Strategy

Generative AI is poised to revolutionize the manufacturing industry and the entire product development life cycle. Manufacturers that capitalize on AI-powered capabilities will be well-positioned to unlock new levels of ideation, design optimization, and stakeholder insights. This enables companies to create more innovative products, streamline processes, and respond more effectively (and quickly) to customer needs.

Establishing a viable framework amid ongoing AI enhancements can be challenging. Many manufacturers are still in the initial stages of implementing and scaling this technology – and these steps are critical. The combination of actual historical data and simulated manufacturing insights can provide Gen AI with a foundation for success today and the agility to address tomorrow’s needs.

The time is now for manufacturers to seize AI opportunities and propel their organizations into a new era of productivity and innovation.

Get a 600% ROI with aPriori

Read Forrester's report to learn how aPriori can cut costs and drive growth