How to Future-Proof Your AI Manufacturing Initiatives with Data

Key Takeaways:

- Quality data is the foundation for AI in manufacturing. Combining actual historical product data and simulated insights expands AI’s field of vision, unlocking new levels of innovation and competitiveness

- Manufacturers use aPriori’s simulated data as a cornerstone of their generative AI initiatives

- Additionally, aPriori applies deterministic/traditional AI capabilities to provide automated guidance (co-pilot recommendations) to optimize 3D CAD models for cost, carbon, and DFM

The Full Article:

The race is on to capitalize on artificial intelligence (AI) and transform AI potential into profits. AI holds the promise to redefine how a business runs – from accelerating product innovation, automating time-consuming tasks, and unlocking new areas of cost savings. So, it’s no surprise that three-quarters of manufacturers in a Bain survey report that adopting AI and related technologies is their top engineering and R&D priority.

But missteps during this critical time could leave companies adrift amid the AI sea change – unable to catch their competitors or navigate new market realities. Despite the hype around AI, early results are mixed. A BCG survey reveals that two-thirds of executives are ambivalent or dissatisfied with their AI progress. And only 31% of companies have met their revenue targets related to AI, and 25% have realized their cost-saving goals, according to the Harvard Business Review.

The key to successful AI initiatives lies in the underlying data quality and the ability to access information from multiple systems. When you incorporate large volumes of quality data generated by manufacturing simulation solutions, you multiply AI’s impact on productivity and innovation exponentially.

This blog outlines how high-quality data fuels successful AI initiatives and aPriori’s role in driving AI success.

- AI defined

- Quality data is the catalyst for AI success

- How aPriori provides an intelligent foundation for AI

- Eaton applies aPriori and AI to accelerate product design

- Set the stage for AI success with accurate data

- Harness AI intelligence to adapt and grow

1. Artificial Intelligence Defined

AI is a group of technologies that simulate some problem-solving capabilities associated with human intelligence, such as critical thinking. These technologies work together to perform cognitive functions such as understanding language/context and demonstrating “complex attention” (analyzing and synthesizing multiple streams of information at the same time).

As a result, AI can identify patterns, make inferences, automate tasks, and create text, images, etc. at a speed and a manner that’s virtually impossible to accomplish manually.

There are two distinct AI categories to group the branches of AI that continue to emerge: traditional AI and generative AI. Both traditional (or classic) AI and generative AI can complement each other.

What is Traditional AI?

Traditional AI, also known as deterministic AI, applies pre-programmed rules and algorithms to make decisions. It is used in manufacturing, logistics, and other industries where precise calculations and predictions are crucial. Traditional AI systems excel at solving well-defined problems and performing repetitive tasks. But it can’t address new requirements without new rules. Traditional AI examples include:

- Expert systems emulate domain knowledge in a specific field. This includes aPriori’s ability to make automated recommendations to improve product designs for cost, product quality, manufacturability (material selection, production process, etc.), and sustainability.

- Decision trees determine next steps based on a set of rules. For example, aPriori uses decision trees in part to prioritize cost outliers, rate the severity of a product design risk, etc.

- Natural language processing (NLP) is used to understand and generate human language. NLP systems are used in search engines, chatbots, and machine translation systems.

What is Generative AI?

Gen AI algorithms analyze large data sets to learn patterns and generate new content. Specifically, gen AI models can create software code, images, text, and other unique outputs that mimic human creativity.

ChatGPT may be the most well-known gen AI example – it’s a large language model (LMM) type of AI. LMMs use machine learning and deep learning for image and speech recognition, object detection, and natural language processing. Data volume is central to LMM’s success. TechTarget estimates that an LLM typically has one billion or more parameters (variables used to infer how to create new content through training).

aPriori Provides AI-powered Insights

At aPriori, we have been applying traditional AI capabilities since our founding. Our analysis engine automatically evaluates the geometry of a 3D CAD model and recommends the most optimal routing steps for cost, carbon, and design for manufacturing (DFM). Additionally, aPriori customers are already applying aPriori-created data to optimize their generative AI and machine learning projects.

Whether companies are adopting traditional and/or generative AI today, one thing is clear: data is the new gold.

2. Quality Data is the Catalyst for AI Success

Harness AI’s full potential by centralizing and organizing high-quality data that cross-functional teams can access and share.

Centralize Fragmented Data for AI-based Operations

According to MIT’s Technology Review, “The lack of universal industrial data is a major obstacle to deploying AI among mainstream manufacturers. That’s because manufacturing data is often localized or specific to a particular industry domain or a company’s operations.”

As such, there isn’t a lot of relevant industry-wide data available for building reliable AI models. For example, industrial equipment manufacturers and consumer electronics brands have significantly different approaches to design and production. However, the financial services sector has data that can be used across industry sub-segments (e.g., consumer banking and asset management) to build relevant AI models for automated customer service and other applications.

To compensate for the lack of industry-wide data available, individual manufacturers can centralize traditionally localized (in-house) data to create robust AI models. This strategy uses 3D CAD models as a focal point because they can contain extensive data about product features and geometry.

Stakeholders across the product lifecycle—from engineering to sourcing—can generate a substantial dataset encompassing aspects like cost, carbon footprint, and manufacturing processes. This enriched 3D CAD dataset can simulate various scenarios in real time to enhance the predictability and efficiency of manufacturing and supply chain decisions.

aPriori has elevated this approach through its partnership with PTC by extending rich 3D model data beyond the design phase to optimize manufacturing processes – and help to reduce a product’s carbon footprint and cost.

Catherine Knicker, Chief Strategy, Marketing & Sustainability Officer at PTC, emphasizes the significance of extending product data beyond design. She noted during a recent aPriori podcast that, “A lot of people talk about the model-based enterprise, which starts with a 3D model. It’s kind of shocking that a lot of companies only use 3D CAD as an efficiency tool for designing, but they’re not using rich content from that model down into manufacturing and into service. 3D CAD models also support sustainability initiatives because data flows much smoother into downstream processes.”*

The Data-Centric AI Mindset

Data quality is also crucial. AI pioneer and Coursera Co-founder Andrew Ng advocates a data-centric approach to AI, which requires a systematic process to define and standardize the information needed to build a successful AI system at scale. “Making this more systematic through principles and [the use of tools] will help a lot of teams build more AI systems,” said Ng. Importantly, AI systems using consistent data improve accuracy and scalability.

Actual historical product data – coupled with simulated insights – can enrich this data pool, providing AI models with the well-rounded perspective necessary for making informed decisions. Here’s how the in-house data sets complement one another and expand AI’s field of vision to provide new levels of innovation accuracy.

How to Capitalize on Historical Data and Simulation Data/Insights

A manufacturer’s actual historical data can include design files of its popular products, highest-margin products, and most profitable in-house production capabilities and suppliers. It can also have detailed performance data regarding company-owned factories and/or production lines.

While a manufacturer’s actual historical data provides a timeline of cost, production volume, etc., this information won’t necessarily help you uncover areas that are costing you time, money, and customer satisfaction (e.g., how do you know if you’re overpaying for a component if you only have quote and payment information?).

To gain these types of insights, manufacturers rely on simulation and modeling to identify opportunities for improvement across the organization – including DFM, cost modeling, sustainability insights, and structural performance (FEA analysis), etc. These simulation applications provide additional analysis and guidance to optimize an array of variables.

Integration with these or other applications/systems is central to harnessing all manufacturing information effectively. With complete control over product data, manufacturers can instantly adjust shop floor labor rates for a plant in Taiwan or raw material cost data to reflect inflationary pressures.

Importantly, manufacturers that understand why there are discrepancies between actual historical data and insights from simulation applications can build precise AI models based on the most accurate information and parameters from multiple types of data.

3. How aPriori Provides an Intelligent Foundation for AI

aPriori’s Manufacturing Insights Platform applies AI to 3D CAD models to automatically recommend changes to improve profitability, manufacturability, and sustainability options. aPriori’s intelligence enables users to simulate multiple variables simultaneously to make data-driven decisions amid increasing design, supply chain, and manufacturing complexity. What used to take weeks or months to measure, report, and reduce product cost can now be done in seconds using aPriori’s AI technology.

Companies use aPriori’s automated manufacturing insights to iterate rapidly using trusted data. With the freedom and speed to access data, product development teams can simulate myriad options to identify new solutions and approaches to increase business value.

Hundreds of leading manufacturers today are creating thousands of design and manufacturing scenarios through aPriori’s simulation engine. They are creating an immense amount of data that can be harvested for further analysis using cutting-edge generative AI and machine learning capabilities. Customers including Eaton are using aPriori simulation data to fuel AI generative product design and other applications.

aPriori’s robust data available for AI modeling includes product cost, carbon footprint, weight, materials, manufacturing process data, and more.

Increase Speed and Productivity

- Capitalize on automated insights: With aPriori, manufacturers can unlock new insights from their existing systems with a click of a button. aPriori’s digital thread ties multiple digital twins together to establish a “single source of truth” for product data in product lifecycle management (PLM) systems – including product weight, tolerance information, carbon footprint data, and more. By contrast, manual analysis of spreadsheet data is time-consuming, may be outdated/inaccurate, and not have important information required to make informed decisions.

- Streamline communication across teams: Centralizing product data has limited value if the relevant teams are siloed. aPriori’s coworking application, aP Workspace, enables users to assign and manage tasks while also providing traceability across product design, cost engineering, sourcing, sustainability, and manufacturing teams.

Innovate Rapidly

- Use updated cost, DFM, and sustainability data: Manufacturers often struggle to access up-to-date information required to make data-driven decisions. Each quarter, aPriori provides updated manufacturing, labor, and material cost data in nearly 90 regions globally. Additionally, aPriori continues to refine and expand its more than 440 manufacturing process models.

- Innovate at scale: How long will it take you to run thousands of scenarios and optimize them for cost, manufacturability, and sustainability? It can take weeks if you use spreadsheets and other traditional processes. But with aPriori automation, manufacturers can compare a range of complex scenarios at scale in real time.

4. Eaton Applies aPriori and AI to Accelerate Product Design

Eaton, a global provider of intelligent power management solutions for consumer and industrial applications, is making a $3 billion research and development (R&D) investment during the next decade to maintain its competitive edge. Additionally, the company is using AI to accelerate new product development while maintaining high quality.

Eaton’s generative AI capability is built on a robust set of historical product design data, coupled with insights across the company’s simulation software portfolio – including aPriori for cost modeling, DFM, digital factories, etc. Eaton’s generative AI models use data from aPriori’s automated insights for cost and DFM to incorporate important product requirements into their analysis. The company’s AI models also use information from other simulation tools such as Ansys.

The company combines this information to create detailed model-based design specifications and properties to support generative AI development.

With generative AI, Eaton runs thousands of design iterations in minutes (or less) and proposes the five-top designs. Eaton then conducts a high-fidelity simulation on the proposed designs to ensure quality and that the outputs match the associated requirements.

Eaton’s AI-Driven Product Innovation Enabled by aPriori Insights

- Accelerated the design time of an automated lighting fixture by 87%

- Reduced the weight of a liquid-to-air heat exchanger by 80%

- Cut design time by 65% for a high-speed gear

5. Set the Stage for AI Success with Accurate Data

How will your corporate culture react to a shift from “informed estimations” to “data-driven insights” from AI?” Manufacturers often struggle with pockets of data that aren’t readily available – whether it’s in a procurement spreadsheet or in a body of knowledge accumulated by seasoned employees. In this common scenario, the data isn’t typically absolute, making it difficult to challenge assumptions.

As you shift to a data-driven model using manufacturing insights, AI, and other solutions, cross-functional teams can connect and view a universal set of product manufacturing information. However, unlocking access to existing data is only part of the solution.

Companies then test and refine their assumptions using a range of tools and applications (e.g., software-based cost modeling recommendations, the CO2e footprint for a manufacturing process, etc.).

Harness Artificial Intelligence to Adapt and Grow

The success of AI heavily depends on the breadth and quality of data it uses. High-quality data ensures AI models are accurate, reliable, and capable of making informed decisions. Poor data can lead to erroneous outputs and failures in AI applications, undermining trust and utility. Ensuring clean, well-structured, and representative data is foundational in training effective AI systems.

aPriori manufacturing insights help to provide the critical data foundation required to leverage AI fully. aPriori is reshaping manufacturing intelligence, setting new benchmarks for accuracy and insights in AI applications, leading to new levels of manufacturing innovation, profitability, and sustainability.

Forward-thinking companies are embracing the future of manufacturing by prioritizing systematic data management and validation practices to harness AI’s full potential – and transform raw data into a strategic asset that drives innovation and operational efficiency.

*Note: comments were edited for brevity.

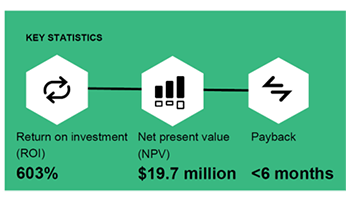

Get a 600% ROI with aPriori

Read Forrester's report to learn how aPriori can cut costs and drive growth