How AI Tools Cut Product Development Costs and Time to Market

Key Takeaways:

- Discover how AI enables manufacturers to launch innovative products faster than ever before to increase profits and cash flow

- Get insights to help move your Gen AI projects out of the pilot phase to transform product development

The Full Article:

Artificial Intelligence (AI) has the potential to transform product design and manufacturing by an order of magnitude not seen since the Industrial Revolution. The promise of new AI tools comes as manufacturers work to balance market demands for innovation with the requirement to cut cost, carbon emissions, and time to market.

Manufacturers are betting big on AI/generative AI (Gen AI) to help develop differentiated products at a fraction of the time required today. Here’s just one example: the semiconductor industry is projected to invest a half billion dollars in AI tools by 2026 to accelerate chip design.

Read more about AI’s advantages for product development, and the requirements to establish a strong, agile AI framework to capitalize on this dynamic technology. Links to each article section follow:

- A brief history of AI in manufacturing

- How AI is transforming product development

- aPriori’s AI-powered insights cut product design and sourcing costs

- Foundational requirements for Gen AI (data quality and more)

- Leverage AI to reimagine product design

1. A Brief History of AI in Manufacturing (It May Be Longer Than You Think)

AI isn’t new. For decades, “traditional” AI technologies have been adding intelligence to data analysis, automating repetitive tasks, and more. Traditional AI includes expert systems, decision trees, and natural language processing (NLP), which is used in chatbots and search engines, and to develop machine learning algorithms for Gen AI.

Traditional/Deterministic AI capabilities are also a cornerstone of the multi-billion dollar software simulation industry (e.g., design guidance for 3D CAD models, manufacturing process simulation modeling, etc).

Gen AI tools like ChatGPT and Microsoft’s Copilot represent a quantum leap in this area because they can produce unique content, including product designs, software code, and other advanced outputs. Forward-thinking manufacturers are using high-fidelity product data – along with market research, user feedback, and other information – to develop new product ideas via generative design.

2. How AI is Transforming Product Development

Product development is a labor-intensive process that traditionally requires multiple iterations before designs are ready for production. These steps are time-consuming and costly – especially when manufacturing teams discover errors or inefficiencies late in the development process.

AI capabilities – including Traditional AI and Generative AI (Gen AI) – can fundamentally redefine the product development process. With the aid of AI, product development teams can explore more design options and examine more possibilities that may not have been considered otherwise, leading to more efficient and dynamic solutions.

Importantly, Gen AI algorithms can also be developed to identify optimal solutions based on feature requirements and constraints (e.g., cost and CO2e targets or sourcing alternative materials due to supply chain disruptions). AI can automatically check designs against a set of predefined criteria to ensure that they meet specifications and standards. Gen AI can cut product design time exponentially and accelerate time to market for a competitive advantage (and greater cash flow).

3. aPriori’s AI-powered Insights Cut Product Design & Sourcing Costs

aPriori’s AI-Powered Design & Sourcing Insights empower product management teams to identify cost-saving opportunities (and potential costly DFM issues) early in the development cycle to mitigate expensive and time-consuming late-stage redesigns. For example, aPriori’s AI-powered insights can assess material choices, manufacturing processes, and factory options by supplier or geography to identify the most cost-effective options.

aPriori provides the only integrated solution to analyze product designs and manufacturing for cost, carbon, and DFM simultaneously. In real-time, aPriori provides guidance to optimize 3D CAD design files for cost, carbon, performance, manufacturing process, and even factory location down to the machine level.

Additionally, aPriori’s digital simulation capabilities allow manufacturers to optimize various design scenarios before committing to physical prototypes. These simulations help to avoid expensive rework and delays. By simulating the entire production process, from initial concept to final assembly, aPriori ensures that every design choice is optimized for both cost and efficiency. This holistic approach reduces direct production costs, shortens the time-to-market, and enables manufacturers to stay competitive in fast-paced industries.

4. Foundational Requirements for Gen AI (Data Quality and More)

Research from McKinsey and others reveals that manufacturers are struggling to move beyond the AI pilot phase due to the complexity of the AI ecosystem and challenges regarding quality design data (among others).

Consider how to address the following foundational AI considerations to capitalize on machine learning, neural networks, deep learning, and other AI algorithms used in Gen AI.

- Simulated Product Insights for Gen AI: The breadth and depth of quality data underpins Gen AI success. Without accurate information to draw on, Gen AI results may be off base or even “hallucinate” (confabulate). aPriori’s simulated product manufacturing insights provide highly accurate data across multiple parameters – including design requirements (tolerances, etc.), cost benchmarks, materials, manufacturing processes, CO2e objectives, etc. AI models can train on aPriori’s high-fidelity design and manufacturing data to expand the breadth and depth of potential design options – and even propose design options that teams would not have thought of on their own.

- Accurate, Current Data: Manufacturers often struggle to access up-to-date manufacturing information. Each quarter, aPriori provides updated manufacturing, labor, and material cost data in nearly 90 regions globally. aPriori also continually refines its AI Engine and expands its more than 440 manufacturing process models.

- Cost Analysis at Scale: Sourcing and procurement teams use aPriori to identify parts and components with the highest costs (or cost outliers) and then apply aPriori’s automated insights to conduct a should cost analysis at scale. One manufacturer has increased the scope of its should cost analysis 10-fold to more than 18,000 parts annually.

- Data and AI Integration: aPriori’s digital thread connects multiple digital twins to establish a “single source of truth” for product data in product lifecycle management (PLM) systems – including product weight, tolerance information, carbon footprint data, and more. This level of integration also enables teams to use their existing workflows or expand processes to include additional stakeholders in the design process. Additionally, cloud-based solutions like aPriori are recommended to reduce data integration hurdles.

- Real-time Collaboration: aPriori’s coworking application, aP Workspace, enables product teams to assign and manage tasks. Team members can post questions directly on 3D CAD design components, such as, “How will changing the tolerance for this component impact pricing/cost?” Cross-functional teams can use this workspace for data-driven decision-making and access a clear project decision history easily.

- Intellectual Property (IP) Protection: Open/public Gen AI applications continually “learn” from queries and refine their responses automatically. So, applications promoting Gen AI could apply users’ proprietary product designs/data to refine their responses. By contrast, aPriori’s Traditional AI doesn’t use customer queries (or other information) to update its AI Engine. Instead, data scientists/teams design and test new Traditional AI rules to ensure high fidelity before launching updates.

- Transparency and Traceability: aPriori’s rule-based system is transparent and traceable, making it easier to understand. For example, users can review aPriori’s design guidance, regional manufacturing cost updates, customer digital factory settings and cost models, and more to analyze results.

5. Leverage AI Tools to Reimagine Product Design

AI’s impact on product design continues to grow as technology in this area advances rapidly. AI-powered tools will further reduce the costs and time associated with product design, empowering manufacturers to bring innovative products to market faster than ever before and develop product strategies that target customer needs and address market pain points to increase profits and cash flow.

By leveraging AI features across both Traditional AI and Gen AI, manufacturers can enhance the functionality of their design processes – enabling product teams to make informed decisions using options that were previously unattainable. Manufacturers who embrace these advancements will be well-positioned to maintain a competitive edge in the rapidly changing landscape of modern industry.

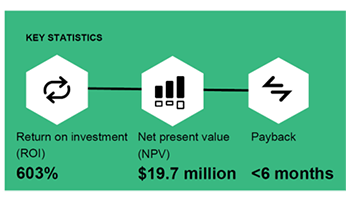

Get a 600% ROI with aPriori

Read Forrester’s report to learn how aPriori can cut costs and drive growth