5 Moves to Evolve from Cost Reduction to Cost Transformation

Key Takeaways:

- Inflation and material shortages continue to be top concerns for procurement teams

- Manufacturers can adopt a cost transformation model via insights that provide real-time supply chain feedback, identifying cost outliers and leveraging fact-based data to improve supplier negotiation skills and costs

The Full Article:

A Deloitte 2023 Global Chief Procurement Officer Survey reveals that cost/inflation (89%) is a top issue that has had the highest impact on their organizations during the past 12 months.

This survey underscores sourcing’s central role in a manufacturer’s success. Because containing cost and increasing cash flow are pivotal to the health of any manufacturer, it’s critical that procurement teams are at the top of their game.

Strategic sourcing includes much more than just identifying short-term cost savings as part of the day-to-day purchasing process. The transition from a cost-reduction approach to a cost-transformation model requires implementing a few high-impact steps to your procurement process.

Specifically, true cost transformation won’t happen without a should cost analysis and the right manufacturing insights solution. What is the best approach to cost transformation in your supply chain procurement? Consider the following moves:

Step 1: Audit All Parts and Raw Materials for Procurement

Compile your current supplier component list including pricing. Identify cost reduction opportunities or cost outliers for these components. Rather than focus on individual parts, run a should cost analysis to determine only those parts that offer a prime opportunity for cost reduction.

Learn how to utilize a should cost analysis to generate timely, accurate manufacturing cost models.

Step 2: Create a Should Cost Estimate to Identify Parts Cost Savings

Before creating a should cost estimate, determine which of your commodity sectors aligns most closely with your provider’s core competency. For example, an automaker in Detroit, Michigan wants to look at its supplier fabricating aluminum sheet metal parts in North America.

Your detailed should cost estimate should be based on as many components in that commodity sector as possible, even if they are produced by multiple suppliers. Ensure that your detailed should cost breakdown encompasses every aspect of the total cost. At this juncture, your goal is the dollar number. Later, you can substantiate your position with details like material utilization, scrap rates, and machine cycle time down to the second to understand your full operating costs.

Although you can manually identify potential cost reduction opportunities, a manufacturing insights solution like aP Analytics can analyze a collection of parts, refining results with more sophisticated filters for faster outlier identification. The automation-driven solution streamlines the cost analysis process, delivering quick, highly accurate estimates pinpointing cost reduction opportunities on overpriced components.

See how Harman uses aPriori to reduce costs and maintain strong supplier relationships.

Step 3: Examine and Prioritize Cost Outliers

Now, with cost metrics in hand, revisit the cost reduction opportunities (cost outliers) uncovered in Step 1.

An outlier is any component with a significant difference between the current price and the should cost estimate. A significant difference is 20% or greater. Look for outlier patterns in components with a common supplier, weight class, or manufacturing process. Respectively, outlier patterns provide clues about a supplier’s business conditions, raw material or handling cost drivers, or production inefficiencies that lead to more specific discussions.

Your components will be ranked from highest to lowest, based on the difference between your annual current spend and your annual should cost. For clarity and better cost reduction decision-making, evaluate potential savings and the percentage difference between the current price and the estimate.

There should be significant savings (current annual spend multiplied by the difference between each component’s current cost and the should cost by its annual volume). Concurrently, a considerable net percentage difference between the estimate and your current price should account for the savings discrepancy in your negotiation strategy.

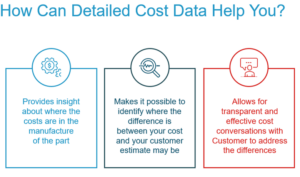

Step 4: Use Fact-Based Cost Data for Supplier Negotiations

Armed with a list of outliers and fact-based should costs, you are now ready to negotiate with your supplier. The detailed breakdown of each outlier’s should cost will facilitate a productive discussion, highlighting cost reduction opportunities. The components that are not outliers in your analysis are assumed to be priced fairly. These non-outlier components are a good negotiating tool, allowing procurement teams to make concessions when advocating for actual outlier price reductions.

Your negotiating power will be more compelling because you have fact-based costs to support your ask. A should cost breakdown, such as an aPriori part cost report, is a great cheat sheet to help you present your secret weapon—educated assumptions about your supplier’s manufacturing methods and costs.

Step 5: Be Confident in Your Supplier Discussion, Then Enjoy Significant Cost Reductions

The beauty of solutions like aPriori is that they provide fact-based data so procurement teams can enter supplier negotiations with confidence. With your should cost data, you will avoid overpaying for outsourced parts. Additionally, you will strengthen your supplier relationships with a trusted source and in the long run, boost the bottom line.

Reimaging Strategic Sourcing for Cost Transformation

A robust sourcing strategy requires more than a spend analysis to identify costs. It also requires a should cost analysis to identify cost outliers, which can help sourcing teams prioritize components and raw materials that require additional investigation and negotiation to secure lower prices.

But for true cost transformation that will have staying power, procurement needs a solution that drills down to the highest component cost drains.

With a comprehensive, highly accurate dashboard, supplier negotiations are straightforward and fact-based. It’s a win-win. You lower costs and the supplier need only negotiate on cost outliers rather than every single line item.

Excel to Excellence: Revolutionizing Cost Engineering with 3D CAD Precision

Fast-track your projects with tools built to quickly estimate 3D CAD design costs!