What to Look for in Manufacturing Costing Software

Key Takeaways:

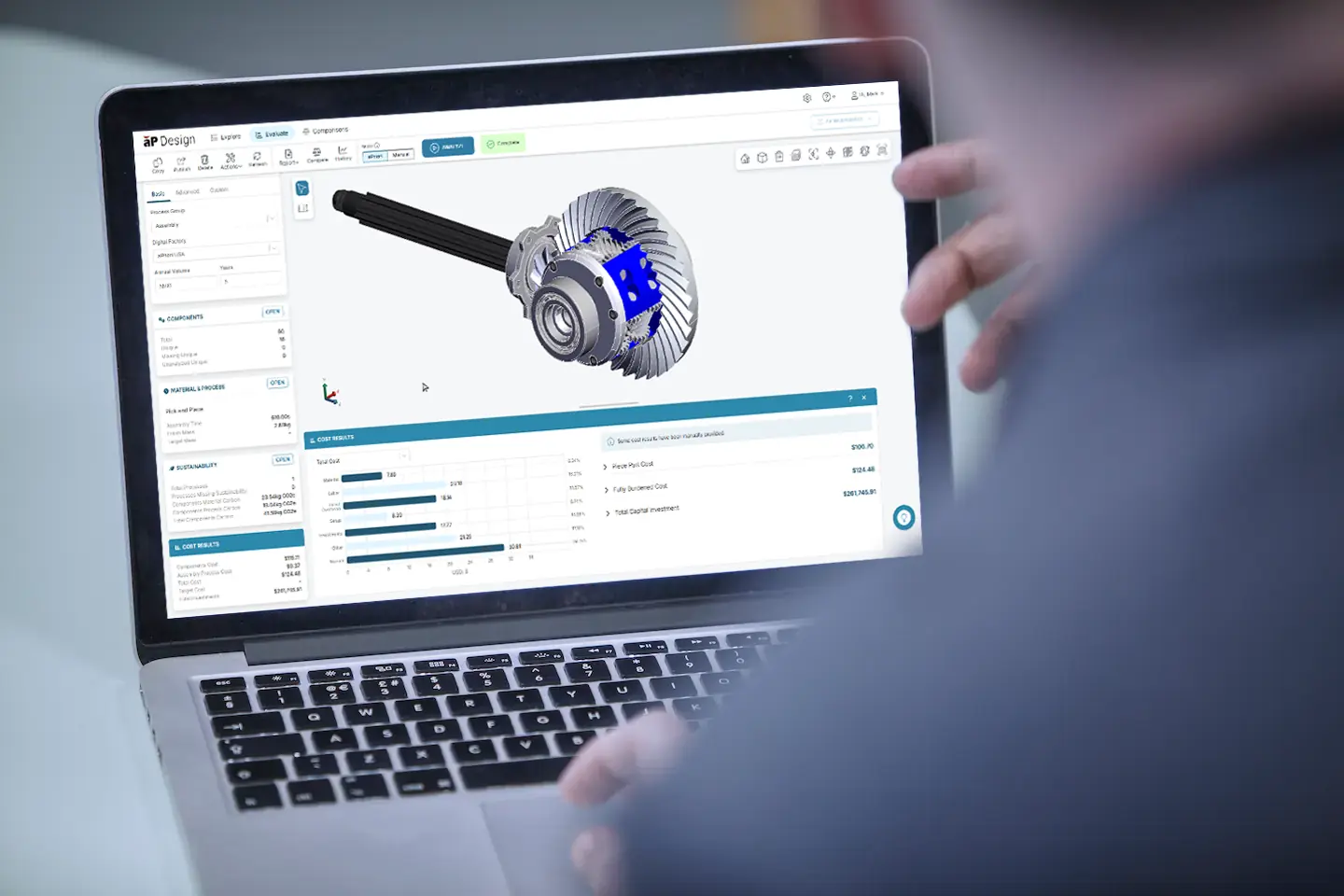

- Manufacturing costing software enables teams to assess the cost of their designs and explore alternatives early in the product development process

- aPriori’s actionable manufacturing cost insights allow manufacturers to strike the perfect balance between cost, manufacturability, and sustainability

The Full Article:

Inadequate costing capabilities present significant business challenges for manufacturing companies. Many manufacturers find themselves no-bidding potentially valuable work due to a backlog in cost management and estimation workflows. Traditional cost estimation approaches often rely on “back-of-the-envelope” methodologies, comparing proposed products to similar past projects or adding a defined profit margin to costs through a cost-plus model.

However, these “close enough” cost methodologies are inadequate in today’s hypercompetitive, highly disruptive product markets. A faster, more precise, and design-centered solution is essential not only for delivering cost-competitive products but also for accelerating time-to-market (TTM) to keep pace with shifting market demands.

Digital manufacturing costing software addresses these challenges head-on, providing highly detailed, component-level estimates. Engineers and executives can leverage these actionable estimates to rationalize decisions on core business concerns, including production planning, pricing, design, supply chain management, and customer-driven product development.

Discover what organizational decision-makers and stakeholders need to consider when evaluating and implementing manufacturing costing software.

What Is Manufacturing Costing Software?

Manufacturing costing software provides granular, real-time, and simulation-driven analysis of a product’s total cost structure, equipping leadership with an accurate perspective on the anatomy of product cost. This comprehensive accounting covers details like raw materials, parts/components, labor costs, third-party services, machine depreciation, and facility time used in production.

As a result, enterprises can evaluate design and manufacturing process alternatives to develop more cost-effective, high-quality products from the outset. Moreover, companies that bring cost visibility into the early stages of product design are more likely to turbocharge a cultural shift toward cost-conscious manufacturing.

Manufacturing Costing Software: 8 Essential Features for Impactful Implementation

Enterprise-grade manufacturing costing software examines the costs, capabilities, and manufacturability of various components, regardless of their complexity. It helps uncover economical part options and integrates cost considerations throughout the entire product development cycle, from design to sourcing.

Conversely, traditional cost estimation tools like Excel spreadsheets are enough for “ballpark estimates.” However, maintaining these non-scalable spreadsheets and their inconsistent data is a cumbersome, time-consuming endeavor that drives an unnecessary divide between design and cost optimization.

Forward-thinking manufacturers use advanced costing software to go beyond ad hoc estimates, bringing true cost rationalization into the design phase. Here are essential software features and capabilities that empower companies to elevate their approach to manufacturing costing:

1. Interfaces Directly With 3D CAD Files. Effective manufacturing cost estimation software removes artificial barriers between design and cost optimization by working directly with 3D computer-aided design (CAD) models. It enables cost rationalization when it matters the most—at the design stage. Consequently, manufacturers can drill down into cost drivers, allowing for streamlined experimentation with changes to the CAD model.

2. AI-Powered Design and Sourcing Insights. Powerful costing software provides high-quality data that works as the foundation or cornerstone for artificial intelligence (AI) initiatives. A solution like aPriori applies AI to 3D CAD models to provide recommendations that bolster profitability, sustainability, and manufacturability.

3. Simulation-Driven Costing. Manufacturing cost estimation software covers many factors to compare costs across design options, sourcing alternatives, and production processes. Moreover, this solution provides full manufacturing simulation capabilities and fine-grained analysis of the efficiency of producing a design using available facilities and procedures.

Manufacturers use these simulated and precise insights to create more cost-effective products, customer-responsive designs, and optimized components throughout the supply chain. For instance, aPriori leverages physics-based cost models that address common manufacturing processes, ranging from sheet metal fabrication to multi-axis machining. Deterministic routings identify the most cost-effective production method and evaluate the manufacturability of all routings defined in the virtual production environment.

4. Greater Scalability. While traditionally delivered on-premises, manufacturing costing solutions, such as aPriori, are now available in the cloud. Cloud-driven approaches provide decisive advantages in terms of scalability, ensuring the ability to expand without maintaining costly physical IT assets. The cloud also streamlines software administration by simplifying tasks like updates, which enables teams to focus on innovation.

5. Three Levels of Automation. Cutting-edge estimation platforms deliver three levels of automation, including:

-

- Part/assembly 3D CAD geometry analysis uses digital models to generate rapid cost estimates and manufacturability feedback

- Bulk costing analysis enables teams to evaluate multiple components and assemblies to uncover more cost-saving opportunities

- Product lifecycle management (PLM) integration analysis streamlines workflows by incorporating automated design evaluation and actionable insights into PLM systems

6. Three Types of Digital Twins. Cutting-edge manufacturing costing software includes three digital twin elements. Explore the different concepts in sequential order:

-

- Digital product twins initiate the process. They refer to 3D CAD models or virtual replicas of tangible assets, such as components and assemblies, and their overall product size and shape. Teams can leverage these twins to determine how design alterations impact product quality, cost, sustainability, and manufacturability outcomes.

- Digital process optimization follows, providing product teams with powerful simulation capabilities to determine the most effective production and routing options. Teams can also use these insights to identify the most suitable workflow that meets their cost, manufacturability, and sustainability targets.

- Digital factory simulation is the final step of the process, providing virtual representations of physical manufacturing facilities. Teams can simulate and evaluate all aspects of production, including the raw materials, machinery, production processes, labor, and manufacturing overhead of global regions. As a result, teams can make more cost-effective, sustainable production and supplier selection decisions.

The digital thread connects the three types of digital twins and their data to help manufacturing teams accelerate and boost their product development operations. Teams also gain data integrity and valuable and actionable manufacturing insights to make appropriate decisions when designing innovations.

7. A Recipe for a Cost-Conscious Engineering Culture. In a traditional design environment, engineers prioritize functional capabilities like performance, reliability, and safety. This practice effectively isolates cost concerns. Manufacturing costing software provides a proven approach to fostering a shift toward a new organizational culture. A consultative sales approach is essential to ensure that manufacturers procure a solution that is geared to their design process and backed by a plan for improvement.

At aPriori, one- to two-day onsite workshops are conducted with new clients. These workshops analyze real-life case studies and demonstrate how engineers leverage aPriori solutions to transform their costing approach in several specialized manufacturing verticals.

8. A Unified Cost Estimation Toolkit. Manufacturing cost estimation software places all these features “under one roof.” It provides one common database and user experience that streamlines administration, dramatically speeds up training, and encourages proactive adoption across engineering teams.

What Are the Benefits of Manufacturing Costing Software?

Incorporating cost visibility into the product design stage is strategically vital, as research suggests that up to 80% of a product’s direct cost is determined during this phase. Due to the significant impact of design on costs, the World Economic Forum (WEF) found that manufacturers are increasingly using digital costing technologies to reduce expenses by up to 30%.

Accurately comparing the costs of different design possibilities is essential in a highly competitive marketplace. This capability provides several business advantages, such as faster quotes for clients, more competitive pricing with higher manufacturing profit margins, and a stronger win rate through precise bids. Manufacturing cost estimation software not only drives internal efficiencies but also provides detailed bids that show potential clients a manufacturer’s commitment to innovation.

Drive Manufacturing Costing Success with aPriori

aPriori delivers transformative manufacturing software solutions across diverse verticals, employing customization, thorough integration, and implementation consulting to ensure success for leading firms worldwide. The software generates a holistic portrait of a product’s total economic cost in a world without markups.

Experience aPriori in Action

See for yourself why the world’s largest powerhouse manufacturers use aPriori to eliminate costs, improve productivity, and reduce carbon.