3 Essentials for Design for Sustainability

The statistics are well-known. Eighty percent of a product’s cost is determined in the design phase. What’s more, it just so happens that 80% of the environmental impacts of a product are also determined in the design phase. How can design engineers improve their product design’s sustainability cost-effectively?

As companies start making the push toward more sustainable manufacturing, many design engineers are tasked with reducing their organization’s product’s carbon footprint. Compounding this seemingly insurmountable task is that many design engineers have no idea where to start the process. How can design for sustainability help your organization? How can you as design engineers best illustrate your potential in this area and then facilitate the move to sustainability?

In this article, we will explain design for sustainability (DFS) and how it can benefit manufacturers. We will also provide guidance on the three essentials for design for sustainability as well as the best practices for implementing it.

What is Design for Sustainability (DFS)?

Design for sustainability is a range of methodologies, which can be deployed to reduce resources used throughout a product’s production and lifespan. From the raw materials through the manufacturing process, design for sustainability is about reducing the environmental impact of a product. The same holds true for the product’s lifespan including the end of it. Right now, one of the highest priorities is a product’s carbon footprint, which comes from the greenhouse gases emitted throughout the product’s life.

aPriori’s manufacturing insights platform facilitates a streamlined, faster method to measure, reduce, and analyze a product’s manufacturing CO₂ footprint. 3D CAD data is quickly evaluated through a geometry-driven analysis to assess the CO₂ footprint. As a result, environmental and cost data drills down to granular, traceable, and transparent calculations. This comprehensive and customizable assessment allows manufacturers to improve sustainability initiatives without sacrificing profits.

Design for Sustainability Misconceptions and its True Benefits

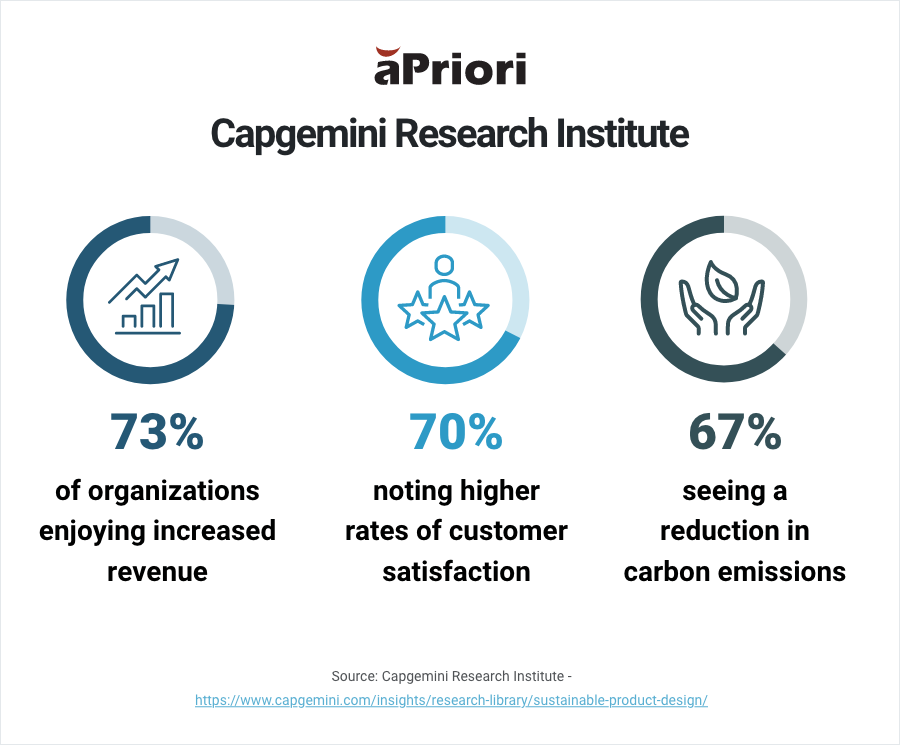

Sustainable product design initiatives can be highly impactful to a manufacturer. Capgemini Research Institute highlighted several notable benefits, including 73% of organizations enjoying increased revenue, 70% noting higher rates of customer satisfaction, and 67% seeing a reduction in carbon emissions.

Despite favorable returns on sustainability initiatives, many manufacturers still haven’t correlated product design’s power in this effort. The same survey indicated that just 26% of organizations conduct regular environmental impact assessments as part of their product design process. The misconception that sustainability initiatives will be too costly is one roadblock for many manufacturers. However, sustainable product design doesn’t necessarily drive up costs. In fact, the Capgemini survey found 37% experienced no cost increases as a result of sustainable product design initiatives.

Costs don’t tell the whole story for sustainable product design hesitancy. Other respondents in the survey noted lack of sustainable materials (55%), a shortage of skilled design talent to support sustainable initiatives (48%), and unavailable technology to implement these initiatives (42%).

What three things are essential for design for sustainability? What should be considered by design engineers to improve product sustainability?

The potential to create products via design for sustainability is vast. The secret sauce lies in the design engineer, a manufacturing culture that supports sustainable initiatives, and a manufacturing insights platform that optimizes not only sustainability but also manufacturability and cost savings. Here are three essentials of design for sustainability:

- Lightweighting: Using less material will almost always mean reduced CO₂. Consequently, it also will have the biggest impact on lowering the in-use phase, which is the largest CO₂ footprint of a product. It is at this juncture where sustainable modeling comes in. aPriori enables design engineers to baseline a product’s environmental impact for reporting as well as identify CO₂ outliers. Additionally, such a tool allows manufacturers to optimize components for cost and CO₂ equivalents while ensuring manufacturability. Several industries are utilizing lightweighting to reduce their carbon footprint and energy consumption. For instance, the automotive industry is shifting to lightweighting for electric vehicles. Fiber-reinforced plastic polymers can be used as structural components in and around an electric vehicle’s high-heat areas, such as battery packs and motors. As a result, the electric vehicle is lighter, uses less energy, and is better performing.

- Design for efficient manufacturing: Design for manufacturability will make the chosen process as efficient as possible. However, you could consider an alternative process, which might offer a lower CO₂ associated with it. Compare suppliers’ environmental impact based on their geographic location to lower the carbon footprint. Reduce material waste based on the process. Finally, evaluate materials’ greenhouse gas (GHG) emissions. All will go a long way to supporting more sustainable products and resource efficiency. Technologies such as aPriori facilitate more efficient and cost-effective sustainable product design. In some cases, aPriori has helped customers create 3-5 times more projected CO2 savings with their design for sustainability insights.

- Design for end-of-life: It should be manufactured so that it is reusable, serviceable, and recyclable. Materials that can be recycled easily should be chosen. Even better, use recycled material at the start to produce the product. All metals can be recycled, but not all plastics. Use fasteners instead of adhesives. They can be taken apart more easily, and each component remanufactured, recycled, or even reused. Most designers likely won’t be thinking about the end of life of their products. If they are, they may want to shorten the life of it to enable repeat sales or build in planned obsolescence. However, it is a viable and impactful step toward environmental sustainability. For instance, rather than throwing out a mobile phone when the battery no longer holds charge, why not make the battery replaceable and recyclable? Fairphone has implemented eco-design in the form of modular phones. They are committed to reducing the phone’s carbon footprint by extending its life as much as possible. To that end, hardware is designed to be more durable and longer lasting. Software updates are regularly provided to maintain the phone’s functionality. The company even provides repair tutorials to extend its usefulness further.

Best Practices for Implementing Design for Sustainability

Now that you’ve got the essentials for design for sustainability, it is equally important to build a culture around this initiative. It does not typically fall to design engineers to build this culture. However, their expertise and the fact that they are the first critical step in developing sustainable products underscores their importance in supporting these initiatives.

The following practices will lay a solid foundation for your sustainability efforts:

1. Promote and support a cross-organizational culture of sustainability

- Clearly define sustainable values and goals for product design

- Create benchmarks to ensure product design can meet goals

- Implement a data-driven approach to identify speed bumps and measure progress

- Integrate technology to support sustainable efforts, especially tools that can analyze and provide alternatives to mitigate costs, supply chain issues, and more

- Commit to training employees, thereby reducing labor and skills shortages

2. Foster sustainable collaboration outside of the organization as well

- Work with suppliers and other partners, leveraging each other’s capabilities to maximize sustainability efforts

- Seek out more local suppliers, partners, and facilities to support sustainability and work around supply chain issues

- A manufacturing insights tool like aPriori can help enhance collaboration and communication across all channels and provide crucial information through the product lifecycle assessment

3. Take a long-term sustainability view

- Focus on long-range outcomes rather than immediate benefits to your sustainability investments. A good example is a manufacturer and recycler of aluminum products. Design for sustainability illustrates the benefits of using those recycled materials. It also highlights that recycled materials may cost more upfront, but there can be tremendous savings of CO2

- Champion and regularly communicate your sustainability mission and efforts to your customers, partnerships, prospects, and stakeholders

- Support circularity or a circular economy, which takes into account the lifetime of a product as well as focuses on recyclability or reusability. For instance, aPriori is working with a leading Tier 1 automotive supplier. The supplier is thinking about circular design and if the materials they are using in the design will be recyclable at the end of the product’s lifespan. Design for sustainability facilitates that process. A Deloitte March 2021 survey found that consumers ranked the top five most important environmentally sustainable or ethical practices as the following:

- Producing sustainable packaging and products

- Reducing waste in the manufacturing process

- Committing to ethical work practices

- Reducing carbon footprint

- Respecting human rights

Design engineers can help move sustainability initiatives forward by bringing more awareness to how design can enact change. The above essentials and practices are a step in the right direction.

Sustainable Design Principles Improve Environmental Performance

The statistics don’t lie. McKinsey noted that consumers value sustainably sourced and manufactured products. More stunning is that these same consumers have contributed to 2.7 times faster growth for sustainable products versus traditional goods – even though sustainable products tend to be priced higher than conventional ones.

The bottom line is that manufacturers can practice stewardship of our ecosystems through more sustainable business models and design strategies. Now is the time to be a critical changemaker in your organization. Lead the design for sustainability charge in the product development phase, ultimately leaving the world a better place today and for future generations.

Get aPriori's Exclusive Guide to Reducing Product Emissions

Read our sustainability guide for manufacturers.