aPriori Fall ’24 Cloud Release Update

aPriori’s fall 2024 cloud release features new AI-powered insights to increase speed, accuracy, and sustainability across the product development lifecycle. The new capabilities in aPriori 2024 R1 SP2 further enable teams from front-end design to back-end manufacturing to increase profitability while reducing risk.

We’ve categorized our new Manufacturing Insights Platform updates into four areas: productivity, sustainability, data and modeling, and platform enhancements.

1. Productivity Enhancements

Access Your Design Scenarios 3X Faster

aPriori now opens parts and assemblies 3X faster on average, and we’ve measured improvements up to 32X faster. This latest enhancement comes without any changes to the aPriori user interface or to your existing workflows.

2. Sustainability Enhancements

aPriori continues to add depth and breadth of coverage for its sustainability insights. We’ve introduced robust sustainability insights for surface treatment processes and expanded reporting to help make product design and sourcing decisions quickly and confidently.

Provide CO2e Estimates for Nearly 30 Surface Treatments

aPriori has significantly expanded its carbon emissions (CO2e) estimates for surface treatment processes to provide additional precision for embodied carbon estimates. aPriori now supports a breadth and depth of surface treatments that range from cleaning and preparation to heat, chemical, and spray manufacturing applications. The 19 new surface treatment processes now available in aPriori 2024 R1 SP2 include:

- Coating/finishing treatments: Abrasive finishing, black oxide coating, cadmium plating, conversion coating, mask benching, mask spraying, powder coating, and vibratory finishing

- Marking process treatments: Dot peen marking and laser engraving

- Surface preparation treatments: Degrease, drying, shot blast, shot peen, and oven curing

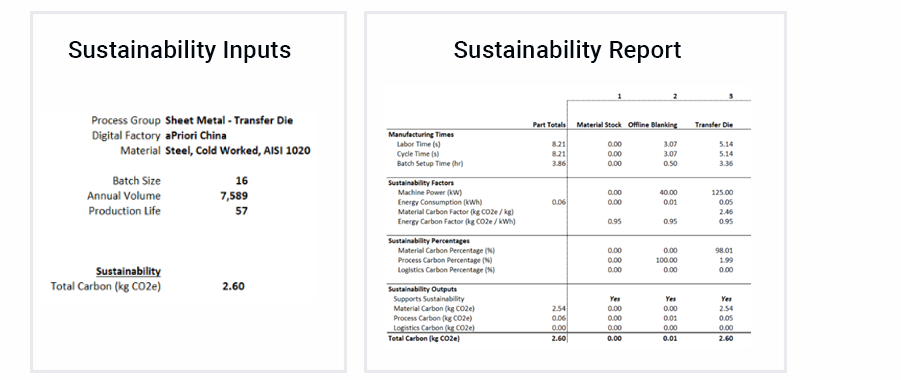

Use a Part Carbon Report to Help Make Complex Sustainability Decisions

With aP Generate’s new aPriori Part Carbon Report, you can create reports focused on sustainability metrics to support the growing need for environmental impact analysis. This new feature expands aP Generate’s flexible notification feature, which enables users to configure reports quickly and easily. New benefits include:

- Develop a single report with CO2e information required to make informed decisions, including material carbon, process carbon, logistics carbon, total carbon, and annual manufacturing carbon

- Create the report quickly and easily. Simply select the Part Carbon Report option when creating or editing a product design workflow

- Use Part Carbon Report for collaboration and feedback. Use the scenario link in the report to discuss options and provide insights in aP Workspace

- Maintain accurate sustainability data tracking by attaching the Part Carbon Report to the appropriate product folder in your product lifecycle management (PLM) system

Use aPriori’s detailed sustainability reports to make critical product design decisions confidently.

Use aPriori’s detailed sustainability reports to make critical product design decisions confidently.

3. Data and Modeling Enhancements

Bar and Tube Stock Shape Recognition

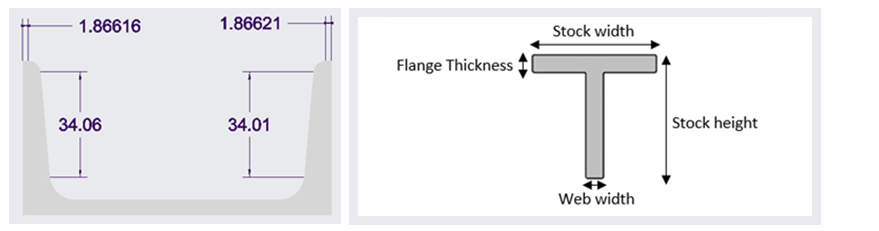

3D CAD models of stock metal forms aren’t always accurate or precise, which can make it challenging to automatically identify standard vs. custom dimensions. aPriori calibrated its AI Engine to account for small modeling errors/variances when identifying Channel, T-Beam, or I-Beam standard stock forms. This new feature simplifies and accelerates the early design process.

For example, the part design on the right is intended to illustrate standard channel stock. However, because the dimensions of the left and right walls are slightly unequal, aPriori previously did not recognize it as a standard stock form. With the enhancement, aPriori now appropriately selects channel stock for this part.

aPriori automatically identifies channel stock even if the associated 3D CAD models aren’t accurate.

Increase Accuracy and Completeness for Machining Part Setup Time

To improve part setup time estimation, aPriori now includes a part’s size as a variable, along with weight, to calculate the time required to complete various setup activities. aPriori also expanded its part setup options to include:

- Part unloading time (aPriori already calculates part loading time)

- Part reorientation time

- Door open and close time

- Clamping and unclamping time

- Blowdown time

These enhancements provide the greatest impact on small parts with low overall cycle times because part setup time represents a larger percentage of total machining operations.

Automated Extraction of Hole and Shaft Tolerances

aPriori now extracts ISO (tabulated) diametrical tolerance specifications for holes and shafts, and displays the tolerance range as it would with numeric tolerances. (To phrase this another way, aPriori automatically translates ISO’s diametrical tolerance grades for holes and shafts to number-based tolerances.)

This means users no longer enter those tolerances manually (or convert them to numerical inputs). As a result, tighter tolerances are automatically accounted for and included when analyzing and calculating cycle times – and thus the product cost.

This new aPriori feature automatically addresses and standardizes hole and shaft tolerance data from leading 3D CAD design software products including PTC Creo, Dassault Systèmes’ CATIA, Siemens NX CAD, and Solidworks 3D CAD.

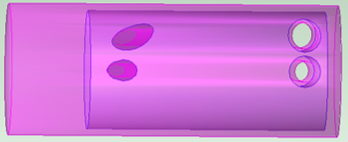

Expand Automation for 3D CAD Model Alignment

aPriori is increasing the precision of costing for components that require multiple processes to complete. A common example is using one 3D CAD model for an initial manufacturing process, such as casting, and a second 3D CAD model to represent the finished machined part.

aPriori compares the solid geometry of the source and finished 3D CAD models to align them in 3D space. In 2024 R1 SP2, aPriori improves automated alignment for axisymmetric models by aligning holes and other co-located features on both the source and finished models.

(Read our summer cloud release [2024 R1 SP1] for more information regarding aPriori’s automated 3D CAD model alignment.)

aPriori aligns co-located features such as holes on both the source and fished 3D CAD models to improve automation and cost analysis.

4. Platform Enhancements

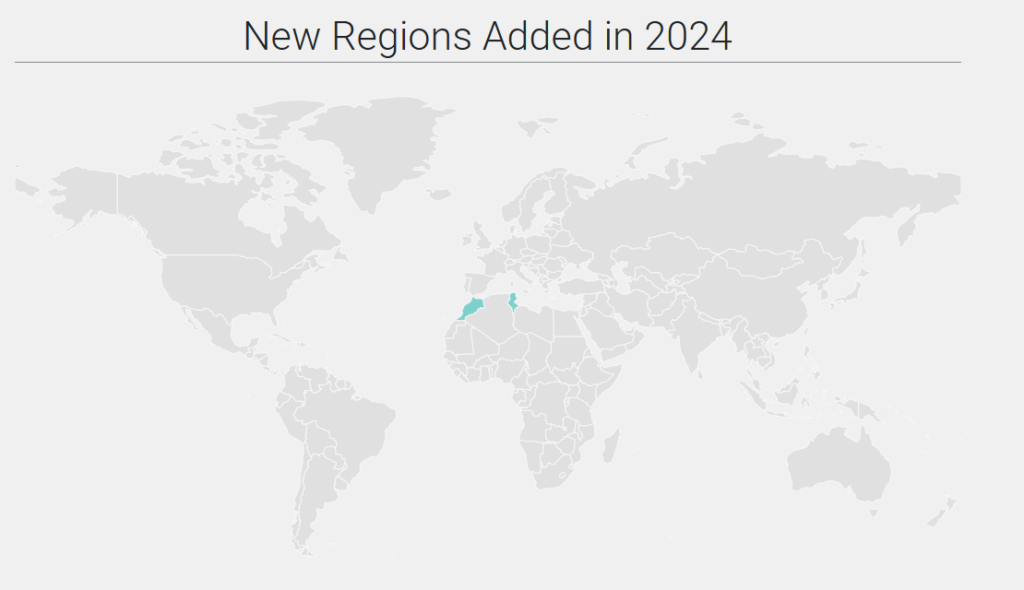

New Manufacturing & Material Cost Data for Morocco and Tunisia

aPriori has added material and supplier production costs for Morocco and Tunisia – and now provides manufacturing cost insights in 89 regions.

Using aPriori’s Regional Data Libraries (RDLs), customers can now compare material costs, regional labor rates, and manufacturing overhead across China (11 manufacturing regions), the United States (10 manufacturing regions), and other countries in Europe, Asia, the Americas, and Africa.

aPriori provides fully burdened manufacturing cost and material cost data in nearly 90 regions – updated four times per year.

Five New Material Purchasing Volume Options

aPriori expands volume purchasing options by adding five new purchase volumes ranging from 30 tons to 10,000 tons. Now, customers have additional opportunities to examine cost options based on purchase factors for various purchase volumes.

Accelerating Value with AI-Powered Design & Sourcing Insights

aPriori is focused on expanding our capabilities to help manufacturers increase profitability, accelerate time to market, boost sustainable manufacturing, and reduce risk.

We announce updates quarterly, and our most recent summer cloud release (2024 R1 SP1) includes:

- Conduct product costing without 3D CAD files in aP Design

- Expanded CO₂e Analysis for Assembly Processes and Subcomponents

- Accelerated draw direction analysis for manufacturing

Please visit our What’s New blog section for additional information about other recent aPriori cloud manufacturing software release enhancements.

Accelerate Time to Market by ‘Shifting Left'

See how manufacturers are eliminating costly development cycles.