aPriori Winter Cloud Release Update ‘24

aPriori’s winter cloud release is now generally available – and is packed with new software features to provide even more value to customers focused on increasing profitability and revenues, reducing risk, meeting sustainability goals, and addressing other critical business issues. We’ve categorized our new Manufacturing Insights Platform features into three main themes:

I.Design Engineering Updates and Productivity

- aP Design Updates

- Electronics and PCBA/Wire Harness Improvements

- Regional Data Library (RDL) Updates

III. Sustainability Insights Enhancements

- aP Workspace: Expanded Sustainability Insights

I. Design Engineering Updates and Productivity

Simplify and Streamline Team Collaboration

When a product design (3D CAD model) reaches a certain level of maturity, the next logical step is to get design feedback from colleagues and teammates. We’ve made it even easier to share 3D CAD models in aP Design with team members via our aP Workspace collaboration application in just a couple of clicks.

Share scenarios quickly and easily by clicking on the aP Workspace option in aP Design.

Refresh on Demand

Full control over refreshing scenarios provides you with added personalization for your design projects. And you can spend more time focusing on cost and carbon reductions.

Previously, aP Design automatically refreshed scenarios to provide the most up-to-date view when users clicked Explore tab. Now, if you already have the scenarios and parts in a view that you need, you don’t need to refresh to see the results. However, if you want to create a new scenario that isn’t in view, simply click the new Refresh button. And we added a timestamp to show when you previously ran your results.

Pre-select Manufacturing Processes

One of aPriori’s most valuable capabilities is optimizing the manufacturing process(es) required during the product design phase. We’re making this process even faster by enabling users to select a manufacturing routing option before running an analysis. Now, users can select material, quantity, manufacturing process – and now routing option – before evaluating the part. This enhancement supports a faster and more streamlined process during design and design for manufacturing (DFM) iterations.

Previously, aP Design required users to run an initial analysis to help determine the most appropriate routing option. Now, users can pre-select this field to save time and gain more control during the very first analysis.

Advanced Scenario Switching

It’s now faster and easier to compare results of alternative part scenarios because you can now access more scenario details beyond just the scenario name. Simply open the full view to see component names, process group, digital factory, created date, and more. This is particularly useful when sticking to the default scenario names or working with teammates’ data.

II. Data and Modelling

Electronics and PCBA/Wire Harness Improvement

Overview

aPriori’s Electronics Module provides manufacturers with the insights to identify cost savings and DFM opportunities. aPriori provides accurate data early during the product development cycle to support design engineers, sourcing professionals, and manufacturers.

The PCBA Costing Module empowers users to generate and cost a PCBA bill of materials (BOM) rapidly by automatically assessing costs associated with individual components and assembly processes. This detailed cost breakdown is essential for cost outlier analysis and quote assessment for new and existing products.

Similarly, the Wire Harness Costing Module details costs throughout design and development. This process breaks out all costs for a wire harness BOM, including: cost estimation for wire and cable preparation, assembly on boards or jigs, and post-assembly testing and labeling processes. These modules extract and utilize BOM-related cost driver information, augmented by aPriori’s proprietary Component Library and user-input data, such as board purchase prices or optional routing selections, to deliver precise and actionable cost intelligence tailored to the specific operational context of each user.

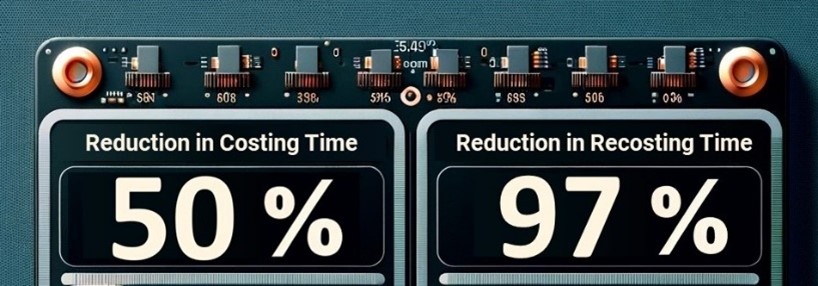

Increase Performance and Cut Costing Times Exponentially

- Reduced Initial Costing Times: To help boost your productivity and accelerate decision-making, aPriori has dramatically reduced the initial costing time for PCBA and Wire Harness modules by approximately 50%. Now, you can cost a PCBA BOM with 500 components in less than two minutes, compared to 13 minutes prior to the enhancement.

- Improved Re-costing Efficiency: We’ve also cut re-costing time for PCBA and Wire Harness modules by nearly 97% to dramatically improve your productivity. Now, re-costing the same 500-component PCBA BOM takes only 50 seconds (less than one minute). This enhancement offers a significant improvement for projects that require frequent updates. Simply modify inputs and re-cost within the same scenario to save time. With aPriori, you will get accurate re-costing within minutes, significantly faster than traditional spreadsheet-based tools.

Gain Added Precision and Efficiency for Modeling and BOM Evaluation

- Refined Wire Dressing Components and Streamlined BOM Evaluation: The Wire Dressing Components within the Wire Harness manufacturing process model now feature more out-of-the-box capabilities to increase calculation accuracy and validate inputs for the BOM. These refinements enable more precise cycle-time estimations and cost calculations for wires and dressings based on length, ensuring cost estimations align more closely with real-world manufacturing scenarios. Additionally, we’ve streamlined the Wire Harness BOM evaluation process to improve usability and simplify an inherently complex process.

- Each RDL release includes comprehensive economic updates including exchange rates, labor rates, material rates, and total manufacturing rates. Global exchange rates have shown remarkable stability in the latest Regional Data Libraries (RDL) update. However, there have been notable changes in labor and material rates – especially in Australia, Taiwan, and Turkey.

- Material rate prices have generally remained stable, except steel prices.

- aPriori’s release notes include a detailed analysis and implications of these economic shifts. Learn more about our RDLs here.

III. Sustainability Insights Enhancements

aPriori offers sustainability insights such as material carbon, process carbon, and total carbon – all of which can be viewed and commented on within aP Workspace. Specifically, users can add scenario, process, and material fields for sustainability insights, view how carbon metrics affect each manufacturing process, and collaborate with others to ask questions or provide feedback on carbon data.

Customer-focused Innovation

Each year, we introduce more than 50 new software releases to help our customers use our Manufacturing Insights Platform even more effectively to improve profitability, increase revenue, reduce risk, and meet their sustainability goals. In addition to the new capabilities detailed here, please visit our Fall 2023 Cloud Release Update for details about other recent aPriori enhancements.

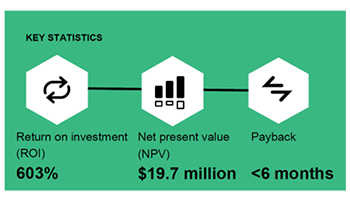

Get A 6X ROI With aPriori

Read Forrester’s “Total Economic Impact” Study to Learn More.