aPriori Fall ’23 Cloud Release Update

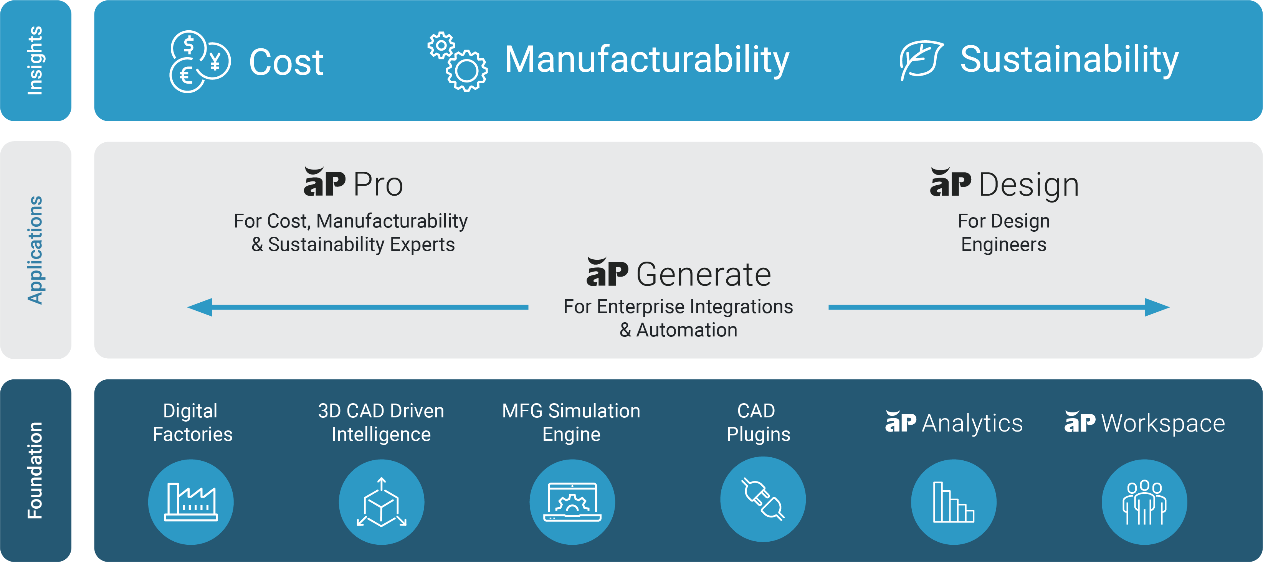

aPriori’s fall cloud release is now generally available to customers. Annually, we introduce more than 50 new software features and enhancements to help our customers use our Manufacturing Insights Platform even more effectively to improve profitability, increase revenue, reduce risk, and meet their sustainability goals.

In the latest quarterly update, aPriori categorizes its new SaaS features and capabilities into three main themes:

I. Design Engineering Productivity

Additionally, here’s a snapshot of our Manufacturing Insights Platform software updates from the past quarter:

- Design Engineering Productivity. Nearly 80% of product cost is set during the early design stages, and aPriori is helping companies shift cost analysis earlier to reduce costs and improve profitability at scale. With aP Design, design engineers can now identify and improve cost and carbon together at the click of a button. And design engineers can be more productive and efficient by analyzing product cost, DFM, and carbon simultaneously. aPriori’s latest release includes updates to easily review scenario history, save and find comparisons, and produce part cost reports at the click of a button.

- Data and Modeling. aPriori now simulates more than 465 manufacturing processes. During the past quarter, aPriori added more than 25 commonly used materials, updated modeling logic for thermoforming and sheet plastic parts, and faster extraction of geometric cost drivers for large assemblies.

- Sustainability Insights. Successful manufacturers are addressing cost and carbon earlier in the design/redesign process. Sustainability Insights are now available in aP Design (for design engineers) and aP Pro (for costing and manufacturing experts). aPriori also expanded its manufacturing process model coverage for carbon footprint to include bar & tube, gravity die casting, and compression molding in this quarterly update.

The aPriori Manufacturing Insights Platform.

Design Engineering and Productivity

aP Design General Updates

Measure and Screenshot

When working on CAD data, there’s a need to capture the accurate size of manufactured parts and components. You can now take CAD model measurements directly in aP Design and take screenshots easily for reference. aPriori now applies 3D dimensions between specific features on the CAD model, or automatically grabs the overall sizes in each direction. This makes it much easier to visualize the most appropriate processes and gain added context for design guidance.

Measure 3D CAD models quickly and accurately with aPriori.

Downloadable Part Reports

Now you can download all scenario data in a single spreadsheet with aP Design to simplify data sharing. Watch the video to learn more.

Tolerances for aP Design

aP Design joins aP Pro to help design engineers identify and fix potential tolerance issues early in the development phase. aP Design now automatically flags 3D CAD designs and manufacturing processes that don’t meet tolerance requirements – providing engineers with an early warning to address the issue by considering a secondary process or a different process.

Watch how to apply tolerances to gain a more precise cost and carbon evaluation.

Assembly Logic (Enhanced)

aP Design’s user-controllable logic for assemblies simplifies the complexity of re-using components and other data management headaches. Now users can set the logic for a specific set of scenarios with assembly components – including private components instead of published components. Or, they can make roll-ups based on maturity status. Expanding your options to create and analyze assemblies the way you want to means less time spent re-costing parts that haven’t changed and more time innovating.

Save, Find, and Compare Scenarios More Easily

Comparison Workflow (Enhanced)

aP Design’s Quick Comparison feature shows changes made to a current scenario – instead of providing side-by-side comparisons of design changes – to provide another way to visualize the impact of your latest scenario updates.

See how to create design comparisons faster with aPriori.

Save Comparisons (Enhanced)

Now, users can save individual scenarios to reduce (or eliminate) rework required to create alternate versions for comparison. aPriori now provides the flexibility to edit existing scenarios along with the convenience of a ready-made comparison to return to, minimizing the rework required to compare multiple iterations.

Revisit design comparisons without rework.

History

aP Design’s new design history feature makes it faster and easier to visualize the effect of different design choices. Now, users can compare each selected design iteration by criteria including DFM risk, cycle time, and CO2e. Design history traceability can support the justification of updates for design reviews while also providing additional visual clarity regarding the impact of updates and modifications.

Watch how to review part history for cost, risk, cycle time, and carbon.

aP Workspace’s New “Project” Feature (and More)!

Watch how you can use aP Workspace to collaborate across departments and teams, assign and manage tasks, and more.

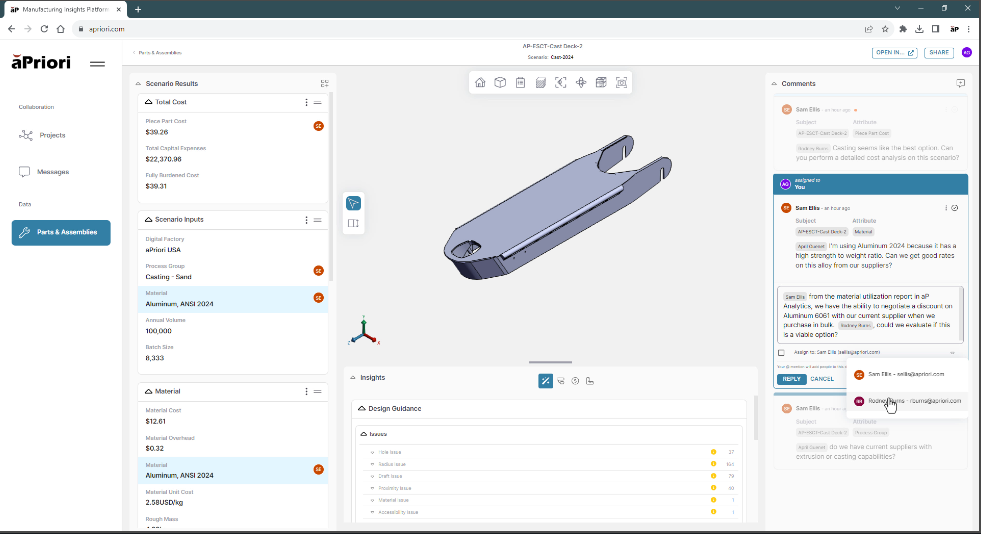

aP Workspace provides cross-functional teams with real-time collaboration and unified product design/manufacturing data in a single environment. aPriori enables users to comment on 3D CAD model data, have project information at their fingertips, and assign/manage tasks.

New Project Feature: Simplify collaboration around initiatives such as new product development, VA/VE selection, product CO2e reduction, cost outlier analysis, and reshoring vs offshoring tradeoffs. Simply select a group of parts to create a project. Then invite other aPriori users to collaborate on components within a project and set due dates for completion.

Reminder: aP Workspace is available for all cloud customers, so get started today.

The new aP Workspace Project feature enables product design, sourcing, and manufacturing teams to streamline real-time collaboration.

New Quick Links and Extended PLM Mappings

Quick Links to aP Workspace and aP Design in PLMs

Watch how to preserve digital thread continuity with scenario links to both aP Workspace (collaboration) and aP Design within your integrated systems (either PLM or file-based integration).

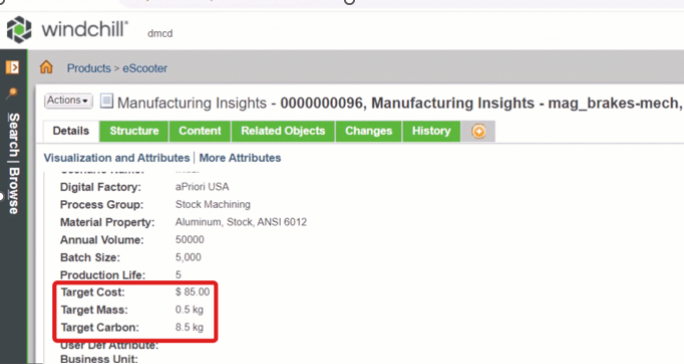

Extended Mappable PLM Inputs (Enhanced)

Expedite outlier and opportunity analysis with the extended mappable inputs for Target Cost and Target Mass values from aPriori your integrated systems. Users can map these new inputs and results to attributes in their integrated system within the Connector definition. This allows users to easily understand if they are meeting their target goals based on current designs.

See how to use extended mappable inputs to work more efficiently and effectively.

Data and Modeling

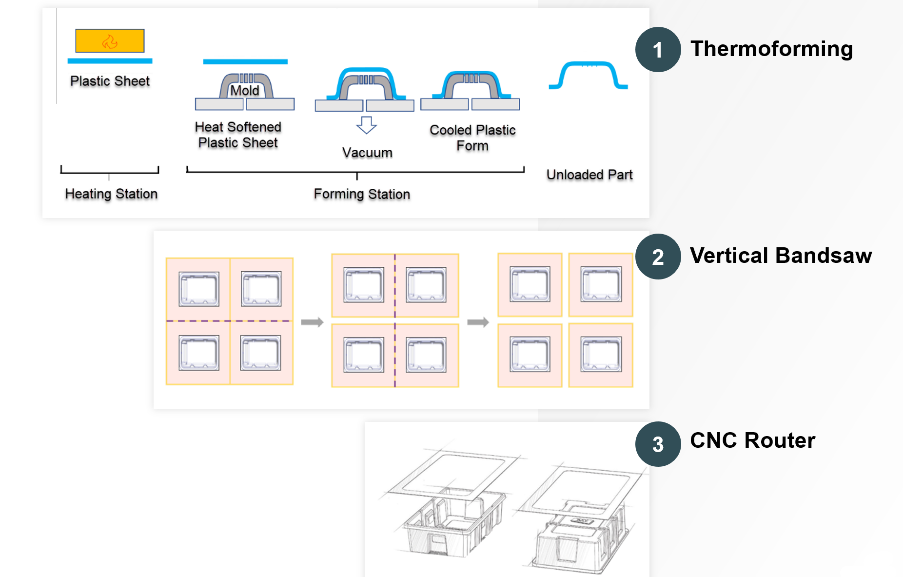

Thermoforming and Sheet Plastic Manufacturing Process Enhancements

Refined Part Spacing and Material Utilization for Thermoforming and Sheet Plastic

aPriori is providing new levels of precision for simulating the thermoforming and sheet plastic parts manufacturing processes. This enhancement improves cost estimate and material utilization accuracy by calculating part spacing based on the height of the part being formed.

Example products from different industrial sectors.

Sheet Plastic: The Inclusion of a Vertical Band Saw Process

aPriori has also added the vertical band saw step to sheet plastic manufacturing to enhance the accuracy of the manufacturing process.

The thermoforming process.

Sheet Plastic: Inclusion of Material Scrap Credit

aPriori now includes options for scrap material and part credit in the aPriori Sheet Plastic Manufacturing Process Model. This addition reflects real-world practices of scrap material or part sales to offset raw material costs.

Machining, Assemblies, and Regional Data Libraries

Machining: Fine Finish Milling Support

The new fine finish milling enhancement eliminates the need for supplementary processes like grinding to streamline the production of top-tier finishes. This advanced feature mirrors advanced milling machine capabilities to optimize the output while reducing cost.

Example of fine-finish aluminum face milling.

Enhanced Geometric Cost Driver (GCD) Extraction for Large Assemblies

Open and re-extract GCDs for large assemblies faster with aPriori’s latest update. Contact Region GCDs, which indicate areas of contact between parts, are used to calculate precise cycle time and cost projections for assembly joining operations.

Additional settings introduced in this release give users refined control over when and how they use Contact Region GCD extraction, streamlining assembly opening times and ensuring optimal performance tailored to specific needs.

Extract GCDs faster when working with large assemblies in aPriori.

Regional Data Library (RDL) Updates

aPriori continues to expand and automate capabilities for its RDL of economic manufacturing data across 87 global regions, which includes exchange rates, labor rates, total manufacturing rates, and material rates for accurate cost estimation and competitive quoting. Notable updates:

- aPriori continues to automate how RDL data is incorporated into Digital Factories. This past quarter, aPriori added 25 new material types to 13 process groups.

- RDLs now default to “high volume” price points to material costs across all proves groups, reflecting the trend of customers typically benefiting from bulk purchasing advantages.

Sustainability Insights

New Sustainability Insights for aP Design and more Manufacturing Process Models

aP Design Gains Sustainability Insights

Getting early insight into the embodied carbon of a design can make a huge difference. By adding sustainability insights to aP Design, product design engineers can visualize carbon equivalent emissions values alongside cost during the design phase. Now, design engineers have the feedback needed to make informed decisions to help introduce innovative products faster.

Sustainability Insights Support for Additional Manufacturing Process Models

The ongoing expansion of the manufacturing processes that we analyze for carbon impact now includes the following with aPriori’s latest release:

- Bar & Tube fabrication: The latest update now covers CO2e of bar and tube parts and broadens Sustainability Insights for the entire aPriori Bar & Tube Fabrication process group.

- Casting & Forging: aPriori added carbon emission metrics for eight gravity die-casting routing processes and built out our coverage in this area.

- Plastics: Compression molding is the latest process in this manufacturing group that aPriori analyzes for CO2 Specifically, for compression molding within aPriori’s Plastic Molding group, the added carbon analysis captures the emissions linked with the Sheet Molding Compound (SMC) or Bulk Molding Compound (BMC) materials and the fabrication processes.

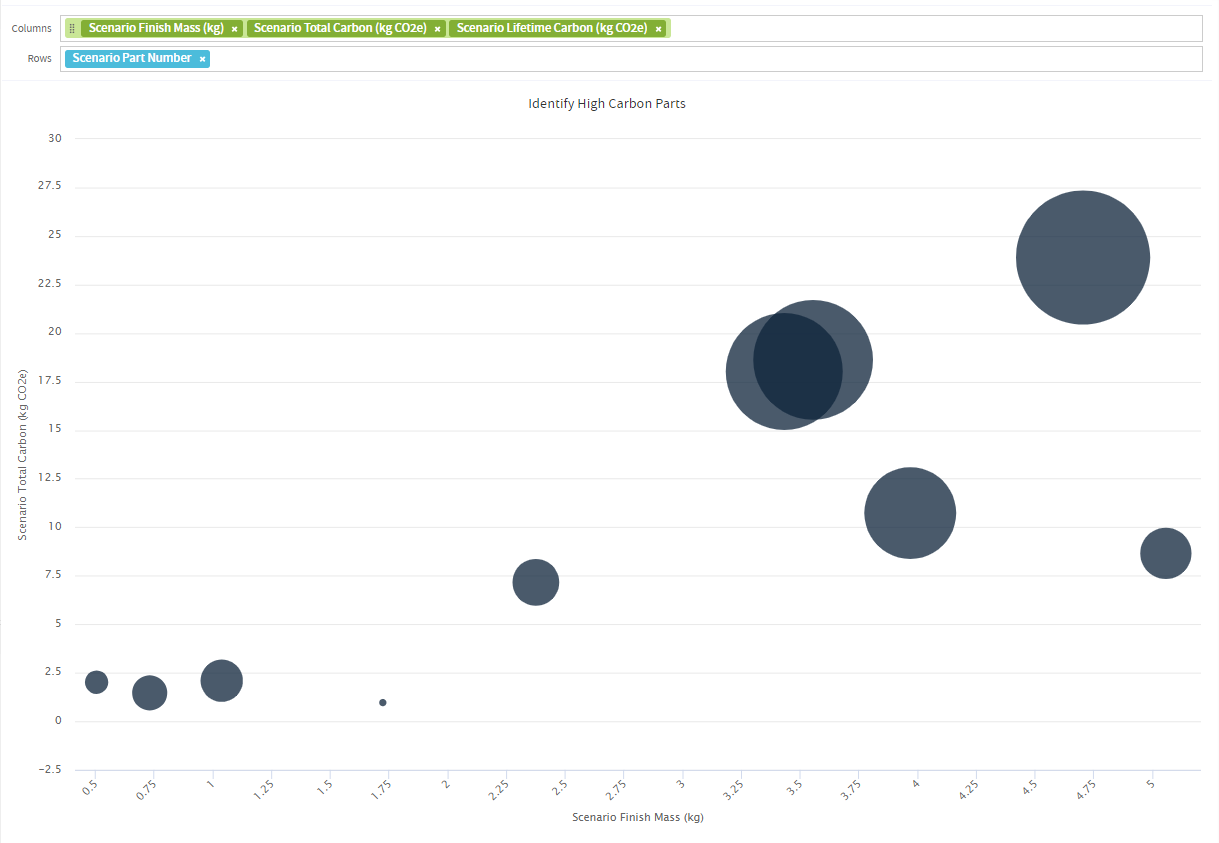

Sustainability Reporting in aP Analytics

Analyze Sustainability Data in aPriori’s Business Intelligence (BI) Application

aPriori sustainability users can use aP Analytics to tap into 17 sustainability metrics within the aPriori ad hoc data reporting domain. This enhancement enables users to craft tailor-made reports based on insights from aP Pro and aP Design. The flexibility offered means users can effortlessly design compelling visualizations, juxtaposing carbon details with manufacturability and cost.

An ad hoc report in aP Analytics shows the lifetime carbon of identified high-carbon parts.

Add Sustainability Metrics Automatically to Your Integrated Systems

aPriori’s extended mappable inputs also enable users to map new sustainability inputs and results in their integrated system within the Connector definition. The following CO2e data can be automatically authored to your integrated systems to help gauge progress toward your sustainability goals:

- Material carbon

- Process carbon

- Logistics carbon

- Total carbon

- Annual manufacturing carbon

Customer-driven Innovation

aPriori continues to develop new features and capabilities to help manufacturers reach new levels of efficiency, capitalize on their digital transformation investments, and gain new levels of agility.

Our quarterly update includes new capabilities that empower cross-functional teams to work cohesively in real-time to take advantage of the expertise and institutional knowledge in your organization. And we also complement our collaboration features with new and expanded offerings across design engineering, cost engineering, sourcing and procurement, manufacturing, and sustainability.

We strongly believe that design engineering and product development teams play a critical role in helping companies meet their product cost, carbon, and profitability targets – and in this latest software release, we have significantly expanded our offering to make designing for cost and carbon easier than ever.

As always, we look forward to your feedback and perspective on how we can provide even more value to your organization.

aPriori named the digital manufacturing solution leader for the second consecutive year