What’s the Difference Between Manufacturing Process and Cost Models?

Key Takeaways:

- Process and cost models enable manufacturers to gain insights throughout the product development lifecycle

- Manufacturers are moving beyond total cost to also optimize designs for manufacturability and sustainability

The Full Article:

Manufacturers continue to invest heavily in equipment and infrastructure to stay competitive. In the U.S., businesses spent $1.15* trillion on capital expenditures between 2010-2019 – a 70% increase over the previous decade, according to the U.S. Census Bureau.

But identifying the right strategic investments is only one metric required for growth. How effectively companies use their manufacturing systems is pivotal to success. Companies that use manufacturing cost and process models can gain insights to increase profits, accelerate time to market, and reduce CO2e emissions.

Defining Manufacturing Cost vs. Process Models

Companies use manufacturing cost and process insights to support their business goals (e.g., should I accelerate output at a slightly higher cost to meet immediate market demand, or should I select a lower-cost, lower-carbon option from a supplier with a longer production schedule to improve the bottom line?).

A manufacturing cost model is a systematic calculation to estimate all product manufacturing cost elements including: materials, direct labor, production, and other overhead expenses. Moving beyond just cost analysis, manufacturing process models enable companies to optimize products for cost, sustainability, and design for manufacturability (DFM) simultaneously in a single platform.

aPriori enables teams to simulate multiple design and production variables quickly to determine the best option. This includes simulating multiple product design options; raw materials (and suppliers); factory equipment, processes, and routings; and regional manufacturing cost differences.

Elements of Manufacturing Cost Models

To determine which product cost factors drive value, manufacturers require the visibility to break down final product costs by design (features and functionality) and manufacturability (manufacturing process and cost variables by factory). Advanced manufacturing cost estimation software provides a simulation-driven analysis of every aspect of a product’s cost structure.

This automated analysis gives designers actionable data on the anatomy of the product cost. This includes the cost of raw materials, material utilization, scrap buy-back, purchased parts/components, labor cost, machine depreciation, and a wide array of indirect facility-related expenses to establish a bottom-line cost (total cost). With aPriori, manufacturers can further refine their cost models based on material costs, process costs, annual production volume, and other variables.

These complex analytical capabilities make cost estimation faster and more accurate, enabling designers to explore cost alternatives during the product design stage. The ability to integrate dynamic, simulation-driven cost estimates with the design process allows manufacturers to consider cost an independent variable of the design process. And providers like aPriori provide advanced cost modeling insights for product designers, cost engineers, and procurement experts.

Aligning Cost and Manufacturing Process Models

Approximately 70% of a product’s cost is established during the early product concept stage. And failure to address cost during this phase can either force manufacturers to cede margin or require expensive and time-consuming redesigns later during the design process.

Design to cost is a methodology to integrate product cost management with decision-making at the design stage. Specifically, design to cost replaces arbitrary cost-cutting targets with fact-based cost insights that product development teams can use to make decisions quickly and confidently. Product managers work with designers and engineers to establish a specific cost target for a new product introduction (NPI) based on current market conditions to maximize profitability.

With aPriori, the cost target is established within our platform and becomes accessible to designers on demand. After each design update, product development teams can quickly run a new manufacturing cost estimate to identify and eliminate cost drivers.

Components of Manufacturing Process Models

Manufacturing process models determine the most effective way to manufacture a product by simulating manufacturing processes and routings (e.g., injection molding and additive manufacturing). Companies simulate manufacturing processes using aPriori’s Digital Process Twins to identify the most appropriate production process for cost, sustainability, and manufacturability.

And our physics-based manufacturing process models allow engineering, manufacturing, and purchasing professionals to explore production alternatives down to the machine level to optimize production costs.

aPriori’s Manufacturing and Cost Models

Our manufacturing process models generate cost, DFM, and sustainability insights from a single platform and user interface. aPriori transitioned from “cost models” to “manufacturing process models” to reflect our breadth of coverage. aPriori provides manufacturing process models for discrete manufacturers across industries and process groups including: additive, casting & forging, electronics, machining, and plastics. Industry-specific examples follow:

Automotive: Reduce Engineering Change Orders

Aluminum extrusion fabrication, roto, and blow molding manufacturing process models assist cross-functional teams in reaching success with pre-production vehicle builds early, reducing engineering change orders. Learn more about manufacturing process models for the automotive industry.

Industrial Equipment: Achieve Targets with Ease

Adapt to large project scopes and streamline product development by quickly locating parts produced cost-effectively through different manufacturing processes. Automatically analyze and identify cost drivers for large sheet metal parts. Learn more about manufacturing process models for industrial equipment and heavy industry.

Aerospace: Manufacture Next-generation Aircraft

Design advanced airframe, engine, and interior components with accurate manufacturing process models. Optimized for the aerospace industry, the process models help improve manufacturing calculation, optimizing performance/weight ratio to reduce fuel consumption and lower total cost of ownership. Find out more about manufacturing process models for aerospace.

Consumer Electronics: Accelerate Design-to-Market

Gain early visibility into the cost impact of design decisions with dedicated manufacturing process models in PCB, PCBA, and wire harness. Achieve faster aggregation and analysis of data across product lines and business units. Find out more about manufacturing process models for consumer electronics.

Think Beyond Cost Models

Cost is only part of the equation for today’s manufacturing brands. Manufacturability can significantly impact product performance and supply chain risk (a product that requires special equipment to produce or additional processes to manufacture can limit the number of suppliers available for that product).

And a corporate commitment to sustainability is increasingly important to customers and investors. It’s also a strategic imperative as manufacturers navigate new carbon taxes and tariffs, and are also increasingly required to report on their sustainability initiatives.

Manufacturing process models evaluate cost, along with DFM and sustainability. Companies using aPriori can simulate how real-world production processes and global factory conditions affect a product’s cost, CO2e, and manufacturability.

In turn, product development teams can quickly conduct “what if scenarios” to understand the effect of one seemingly minor change (e.g., how will using a different manufacturing process reduce waste or accelerate production?). aPriori provides the only manufacturing intelligence platform to optimize products for cost, manufacturability, and CO2e mitigation in real time.

*U.S. Census Bureau reporting does not include the farming industry.

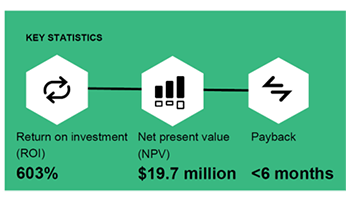

Get 600% ROI with aPriori

See How aPriori Can Boost Your Business