What Is the Green-Golden Ratio? Achieve Sustainable Development and Profitability

Key Takeaways:

- The balance of the “golden ratio” is seemingly everywhere in nature.

- Discover how the “green-golden” ratio can guide sustainable development by balancing cost and CO2e

The Full Article:

The golden ratio has existed since the dawn of time and is observed in crystal, plant, and animal structures. The golden ratio’s mathematical definition is attributed to the Fibonacci sequence, approximated by 1.62:1. This ratio can be used to explain the relationship between elements of some naturally occurring structures.

What is the green-golden ratio? Today, it is an unknown, yet-to-be-defined value; it could be one that indicates the ultimate harmony of economically viable and sustainable products or businesses.

How can manufacturers successfully address the precarious balancing act of achieving both sustainability and profitability? The green-golden ratio may be the key.

Finding Sustainable Development Opportunities with Manufacturing Analytics

Although manufacturers can lower their carbon footprint at the grassroots level (i.e., having employees ride bikes to work), true carbon reduction requires deeper analysis from greater insights.

Manufacturing analytics can be particularly helpful when reducing carbon emissions from purchased goods and services that rely on suppliers (production CO2e). How their products will be used (through-life CO2e) can also be a significant factor. However, it is a balancing act requiring trade-offs (design, materials, location, process) that can vary from industry to industry.

Manufacturability, weight, and energy usage can influence carbon emissions reduction and sustainable development goals. An aerospace organization can light weight a plane so it uses less energy. However, it often requires keeping control of costs for more expensive components made from carbon fiber or titanium. A consumer goods company’s carbon reduction might focus on the production of CO2e, reducing material waste and long supply chains.

Then there is the profitability factor. It shouldn’t be sacrificed over sustainability and vice versa. Though more complex to achieve, both are possible. With so many variables depending on the individual industry and the product design, a digital manufacturing solution goes a long way to balancing both by providing impactful data for real-life scenarios.

A Virtual Simulation for a Real-life Scenario

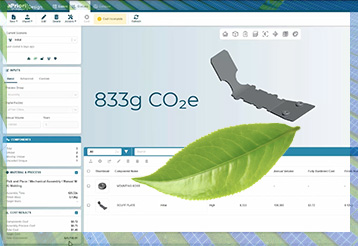

By incorporating real-life scenarios into virtual product design simulations, manufacturers can more efficiently attain the green-golden ratio. aPriori’s manufacturing insights platform provides actionable insights to improve manufacturability at every stage of the product lifecycle thus reducing energy consumption.

Example: Increase Material Utilization

The design of components and the elected manufacturing process can have a significant impact on material utilization. aPriori identifies the “outliers” and offers greater insights into the main drivers. The product design team can then evaluate alternative designs, processes, and materials that yield the most cost-effective and sustainable results.

Example: Material Selection and Performance

Other manufacturing insights reveal excessive wall thicknesses beyond best practice within cast or molded components. Eliminating these without compromising structural integrity will result in lower material consumption and machine energy.

For an injection molded component, the manufacturing insights may recommend a more expensive and carbon-intensive material that could be used to achieve a more structurally sound part. The final design could, therefore, contain less material, with additional carbon and cost savings realized through process time reductions.

This is a perfect example of the green-golden ratio in action, but this can only be a reality if insights are identified continuously, quickly, and in the early stages of detailed design.

Example: Reduce Embodied Carbon During Design

aP Design can be leveraged to address sustainability and cost associated with a product’s materials and processes. The carbon footprint of an aluminum flywheel in a power drill mainly comes from the material, with some contribution from the die-casting and finishing processes. A particular grade of aluminum contributes 3.17kg of CO2e from the material alone. A rapid evaluation of a steel alternative with thinner walls provides the same mechanical performance with an 85.5% reduction in CO2e and at the expense of a meager 3.3% increase in cost.

This small cost increase can be justified since customers want more green products. Moreover, this information can also help procurement make more strategic supply decisions while still in the product’s design stage.

The complex equation of raw material utilization and processing carbon versus cost for various material grades, manufacturing locations, and production energy sources can be evaluated in seconds. Such timely and “on-demand” evaluations support trade-off decisions before critical development stage gates. They also support key near and long-term business planning processes.

Calculate Internal Carbon Pricing To Quantify the Green-Golden Ratio

aPriori can support an evaluation of cost versus carbon by putting a price on CO2e for parts, work packages, or entire products. This evaluation calculates Internal Carbon Pricing (ICP) using various industry, geographic, tax, or levy factors.

There is a “price” on the carbon footprint. It may be a real cost or a subjective cost, based on where and how that carbon footprint impacts that manufacturer.

Side-by-side comparisons can be analyzed to determine the best course of action for your operations using a single measure for cost and carbon – money. You may have to pay more in better wages for workers and higher machine rates in the Nordics or Switzerland while you lower your carbon in the process. If profitability is more important, rates in India will be more favorable but your carbon will be higher due to a more complex supply chain and looser CO2e regulations in that part of the world.

aPriori’s regional data libraries allow manufacturers to compare multiple manufacturing insights from region to region and help drive towards a green-golden ratio. Product designs evolve with all product development team members looped in – to meet costs, lower carbon, and mitigate supply chain issues and product launch delays.

aP Analytics uses the insights from the digital factories to calculate this ICP in regions throughout the world with should cost as the baseline. A manufacturer’s cost of carbon factors can be modelled and the cost baseline augmented, generating the true ICP cost for components. This provides indicators as to where parts should be manufactured to meet sustainability, risk, and cost objectives. Perhaps the data indicates that Brazil offers the lowest price point AND carbon footprint for your specific product. Now you’ve found your green-golden ratio – sustainable development and profitability in making that product.

aPriori Helps Manufacturers Accelerate the Green-Golden Ratio

The 2030 Agenda for Sustainable Development, adopted by all United Nations Member States in 2015, provides a shared blueprint for peace and prosperity for people and the planet, now and into the future. The 17 Sustainable Development Goals (SDGs) are a global partnership and an urgent call for action by all developed and developing countries to end extreme poverty and other deprivations. This effort must be in tandem with strategies to improve food security, well-being and education, improve gender equality and other inequalities, and spur economic growth – while simultaneously addressing climate change and working to preserve our oceans and forests.

Manufacturers that are truly “green” achieve both profitability and sustainability. Profitability enables them to succeed and work towards greater sustainability. Sustainability, in turn, engenders customer and brand loyalty, leading to higher revenue. It is the balancing act all manufacturers should strive towards. aPriori can help them get there.

Get aPriori's Exclusive Guide to Reducing Product Emissions