Keys to Making Strategic Investments Amid Economic Turbulence

- High interest rates are causing some European manufacturers to cut spending

- But conserving cash today could jeopardize future competitiveness

- Learn how Thompson Aero Seating is addressing short- and long-term goals

Rising interest rates and high inflation across Europe are forcing many manufacturers to re-focus on short-term pressures at the expense of making strategic decisions for long-term growth. And many companies have been taking this approach since the COVID-19 pandemic began in early 2020.

Companies across Europe and the globe face ongoing uncertainty. For example, U.K. manufacturers continue to evaluate current opportunities for growth while simultaneously asking the Bank of England (BoE) to clarify its fiscal policy to support manufacturing and related industries.

Against this backdrop, the U.K.’s NatWest and other large European lenders are raising concerns that companies that fail to plan for future opportunities are jeopardizing their future growth, market competitiveness, and profitability. NatWest believes that short-term investments should not take precedence over the long-term investments, as both are critical to a company’s survival in tumultuous times.

Navigating Economic Headwinds

How can manufacturers address their immediate needs – such as reducing costs – and gain new capabilities that provide a catalyst for future growth? Learn how one U.K. manufacturer’s investment in aPriori paid for itself within three months and is now paving the way for long-term success.

Thompson Aero Seating Navigates High European Interest Rates and Inflation

Headquartered in Northern Ireland, Thompson Aero Seating specializes in designing and manufacturing premium airline seats. Virgin Atlantic, JetBlue, Singapore Airlines, and other carriers use Thompson Aero Seating to provide their first-class and business-class passengers with an optimal in-flight experience. Thompson Aero Seating offers four primary product lines, and also develops customized products (e.g., Virgin Atlantic’s Retreat Suite features a customized version of its Vantage XL First design).

This variety in products to manufacture and production volumes makes it challenging for Thompson Aero Seating’s cost team to evaluate if all supplier quotes are in line with inflation and other current market costs. The company was receiving higher supplier quotes but lacked accurate, real-world cost insights and breakdowns to validate the additional expense.

Thompson Aero Seating wanted advanced costing technology that could integrate seamlessly with its existing computer-aided design (CAD) and product lifecycle management (PLM) systems. The ideal costing solution would address short-term issues, provide a quick return on investment (ROI), and position the company for long-term success.

In July 2022, Thompson Aero Seating deployed aPriori’s automation-driven Manufacturing Insights Platform with should cost capabilities. aPriori should costing deconstructs the total cost structure of a component to uncover cost discrepancies in the supplier’s latest quote. It even considers real-world labor, electricity, and material costs, ensuring the company only pays a fair market price for externally sourced components.

Thompson Aero Seating & aPriori: Short-Term Wins and Long-Term Benefits

Despite the U.K.’s high inflationary environment, Thompson Aero Seating was able to achieve the following results quickly using the aPriori platform:

Get Payback in Months

Thompson Aero Seating realized a quick payback on its aPriori investment in just one fiscal quarter. aPriori’s manufacturing cost modeling software makes it easy to generate detailed insights into cost structure that can be used to inform supplier negotiations.

“We have used aPriori to target cost savings on our existing library of purchased machined parts and were able to achieve a ROI for our total investment within six months by focusing on the largest cost/volume components on our MRP system.

“We were able to train up a small multi-disciplinary team across supply chain, manufacturing and engineering to accomplish this with the aid of excellent aPriori support through formal workshops, ad-hoc calls and onscreen reviews which were invaluable.”—Paul Mulholland, Business Systems Engineer, Thompson Aero Seating

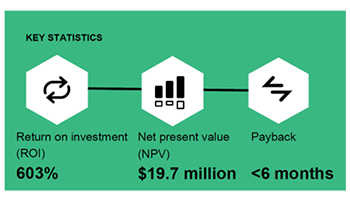

When Forrester conducted its Total Economic Impact (TEI) study, it found that several other companies realized aPriori payback in less than six months. It was also determined that these organizations received a 603% return on their aPriori investment.

Improve Productivity

aPriori harnesses the power of the digital twin CAD model, weaving in the digital thread to provide critical manufacturing insights. With this level of automation, product teams can generate cost, manufacturability, and sustainability insights in minutes. aPriori even centralizes the data to seamlessly bring teams together and collaborate to make better cost, design, or sourcing decisions.

With aPriori’s manufacturing insights, design engineers and other key players receive early design-stage feedback, indicating potential issues. Designs can now be modified collaboratively and quickly at the lowest cost early in the product development process. Further, aPriori’s accurate data and recommendations enable less-senior engineers to embark on projects formerly reserved for only the most technically skilled colleagues. This enables companies like Thompson Aero Seating to mitigate labor and less-skilled workforce shortages, which contribute to product delays.

Drive Profitability

Today’s chief financial officers (CFOs) and other c-level executives are under pressure to ensure that their investments are yielding results quickly. This is especially crucial at a time when European interest rates are rising, and inflationary pressures remain strong.

The CFO considers a technology investment to be effective if it delivers annualized savings and maximizes the capabilities of existing systems. aPriori makes this possible.

aPriori’s automation-driven solution leverages the power of the digital twin to “unlock” insights from a manufacturing company’s existing systems. aPriori provides manufacturers with the knowledge they need to design the sustainable, high-quality products that customers want at the lowest possible cost.

With aPriori, manufacturers can not only evaluate their designs in real time, but also boost workflow efficiencies to launch products faster. At its core, aPriori enables manufacturing companies to achieve their profitability goals while also enhancing their innovation to remain competitive.

Better Visibility for Better Decision-Making

Rising European interest rates and high inflation are causing economic challenges for EU and U.K.-based manufacturing companies. Fortunately, by implementing aPriori into their existing operations, manufacturers obtain the visibility required to navigate inflation and make data-driven decisions to satisfy market demands quickly. Organizations like Thompson Aero Seating rely on aPriori to adapt to changing inflationary challenges, increase team efficiency, and win today and in the future.

See How aPriori Can Boost Your Business

603% ROI. 10% procurement spend reduction. 70% increase in design efficiency.