How to Get Ahead of Rising Supplier Costs: An Inflationary Tale

The pandemic and war in Ukraine have illustrated the domino effect that events can have on all facets of our lives and businesses. Supply chain issues, inflation, and higher fuel costs continue, creating a strain on the bottom line of so many organizations. These disruptions necessitate the use of manufacturing simulation software by organizations to better manage inflation and rising supplier costs.

In this article, we will explain how digital manufacturing simulation software can be used to help you identify losses on your company’s financial balance sheet. We will share with you how to strengthen your position with customers when discussing price increases, using detailed cost data.

Address Inflation and Improve Profitability

One approach to managing inflation, while ensuring profitability, is by leveraging digital manufacturing simulation software. It is an effective tool, especially in this environment, as manufacturers are increasing prices due to inflation and supply chain issues. The detailed cost information generated by these software tools helps a manufacturer/supplier strengthen their price increase position with customers. Here’s how:

-

Mitigate Inflation Effects on Your Bottom Line

Manufacturing simulation helps manufacturers/suppliers understand how inflation alters the bottom line and identifies where you can save money. These findings enable you to explain to your customers how inflation impacts the cost you are passing on to them. These fact-based conversations will facilitate a higher probability of a win-win scenario during the negotiation phase. Manufacturing simulation creates a digital factory that mimics your physical factory, virtually and automatically replicating each step of the manufacturing process. It calculates cycle times and material consumption, translating that to cost by using your labor, overhead, and material cost. The result is a detailed cost breakdown of the part or assembly. (Welding costs, as well as mechanical assembly costs, can be included.) The process of modeling your factory is usually complete in about three months. Armed with the digital factory, you can cost portions of your parts’ portfolio – segmenting it by customer, by product, or process areas – whichever you feel poses the greatest risk. Once you have costed your parts, you will gain a clearer picture of your costs and financial strains (figure 1).

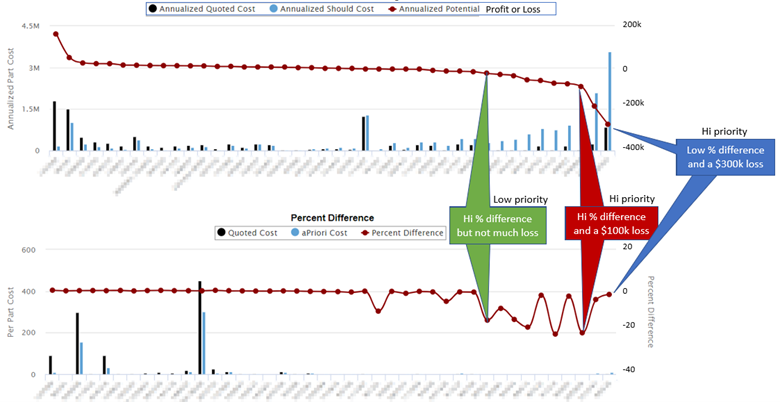

Figure 1: Understand how to prioritize parts for greater profitability

We recommend that you prioritize items that represent the greatest loss to your bottom line and where the percentage is the widest between your cost and the price you charge the customer (quoted cost). The graph above is a compelling, visual analysis to better understand how to prioritize parts for greater profitability and where price hikes for customers take precedence.

Additionally, consider acting on the parts where the percentage difference between your cost and customer price (also known as your loss percentage) is small. It may be easier to gain customer consensus on a modest price increase over a larger percentage. A small tweak could be the difference between staying in the red or getting back in black.

Pro Tip: It is a good fiscal move to deprioritize low sales volume items, even if there is a healthy negative percentage difference between your cost and customer price. Your time should be spent addressing the largest overall losses first.

2. How to Approach a Price Increase with Your Customers and Strengthen Relationships

It can be challenging passing on a price increase to your customers. Simulation tools provide you and your customers with the data you need to engage in fact-based conversations with them. This detailed cost analysis helps initiate a dialogue with your customers as well as educate them regarding your capabilities and available capacity as they relate to the cost of their part(s). Inflation is an unpleasant fact. The better equipped you are to illustrate exactly how their parts are impacted, the more likely the customer will be to accept the increase.

Customers are becoming more knowledgeable about negotiating supplier prices, particularly in times of inflation. Although manufacturers/suppliers might view it as negative, it is actually a great opportunity to strengthen customer relationships. The more educated the customer, the more prepared they are to come to the discussion with fact-based details.

3. Instill Trust and Transparency in Customer Negotiations

A manufacturing simulation solution can be used to foster a meeting of the minds between manufacturer/supplier and their customer when it comes to pricing. It can provide clarity for the customer regarding more accurate cycle times or processes that are required and why they are necessary. Occasionally, some processes are no longer required. In these instances, the price could be even less than the customer initially estimated.

Either way, manufacturing simulation is an ideal tool for exposing an area where their estimate and your cost differ. At this time, you can explore options together, ultimately strengthening your customer’s trust in you through transparency and a detailed, fact-based discussion that is favorable to both of you.

Real Life Example: A manufacturer and their customer were discussing a medium-stamped part. Both agreed on material costs. However, the manufacturer’s cost differed from the customer’s estimate. Further discussion revealed the customer’s cycle estimate was about 50% of the supplier’s time. After discussing the details used in the part’s production, it was revealed that the specs required an inter-stage inspection. This was a master check of all manufactured features required after each step (eight stages), doubling the cycle time. However, this requirement was only intended during the first year of production. Once the requirement was removed, the part price decreased to an amount acceptable to both parties. Because the customer received a lower part price and the manufacturer’s cost to produce that part decreased as well, this resulted in a win-win scenario. In this instance, the cost estimate details that manufacturing simulation software can generate worked in favor of both the manufacturer and customer.

4. Use Manufacturing Simulation to Prioritize Costs and Negotiate with Customers

Once a manufacturing simulation solution is implemented, it will calculate cost the same way every time incorporating your rules and current costs. It quotes more consistently, faster, and with lower risk, identifying potential DFM issues early. As a result, you can clarify issues with customers or account for the manufacturing difficulty in your quote.

Example: Manufacturing simulation software will indicate if a hole is too close to a bend, potentially deforming it while bending. If the hole is required to meet a tolerance, and the defect is not caught early, you might have to absorb the added cost of manufacture or rectify it through expedited new parts and reshipment or a product redesign. (Or worse, deal with the customer’s back charges due to quality rejects.)

We have seen how manufacturing simulation can help our customers manage inflation by identifying where they are losing money, and where they should prioritize profitability. aPriori’s manufacturing simulation technology will allow you to build a persuasive case to explain price increases to customers. Best of all, it offers the opportunity to create a win for both sides of the table. Your customer will enjoy greater pricing transparency, and in some cases, even a price reduction if costs go down for you as well.

Create great pricing transparency between you and your customers

Learn how to explain price increases with digital manufacturing simulation software.