Navigate the High Cost of Sourcing Materials to Boost Profitability

Key Takeaways:

- With market-driven cost and manufacturing data, sourcing teams can avoid costly missteps and delays in material procurement

- A digital manufacturing solution like aPriori provides timely and accurate should cost data for effective supplier negotiations (materials, labor, machines, etc.)

Full Article:

Material shortages and supply chain management disruptions continue to flare up regularly as a reminder that manufacturers should still expect continued spikes in volatility. According to Tim Fiore, chair of the Institute for Supply Management’s (ISM) Manufacturing Business Survey Committee, raw material prices will rise by 3.2% in the first five months of this year. Projected increases for 2024 overall are lower than the past few years when prices surged between 4.1% (2023) and 25% (2020).

Price fluctuations present challenges in direct material sourcing and the effectiveness of manufacturers’ negotiations and supplier relationships.

Cost engineers and others involved in procurement require accurate, timely data to evaluate supplier price increase requests and determine whether the higher quotes truly align with material cost increases. For buyers, the objective is to understand how rising material costs should impact a product’s piece part cost so they can avoid overpaying.

Watch this video and then leverage aPriori to overcome your procurement challenges.

Address Rising Material Costs with aPriori’s Manufacturing Cost Models

aPriori’s digital factory enables procurement and cost engineering teams to get an accurate cost model on a material rate increase to see how it impacts the total product costs. Simply select all parts used in a product and add them to a “rollup” in a digital factory. Within an intuitive material selection screen, cost engineers can change material rates to automatically re-cost the parts included in the rollup. aPriori’s digital factories provide Regional Data Libraries (RDLs) for 87 global regions, updated quarterly, to access supplier material rates and other related costs,

Utilize our product material analysis cost calculator to see how prices might fluctuate.

aPriori’s accurate cost estimates detail how much a component or part should cost given a specified material rate increase. Procurement then knows how much they should pay a supplier for parts, eliminating hours traditionally spent evaluating one component at a time. Cost experts can use these estimates to identify the best cost savings opportunities and, in turn, support and help maximize the sourcing team’s supplier negotiations.

How aPriori Delivers Highly Accurate Part Cost Estimations

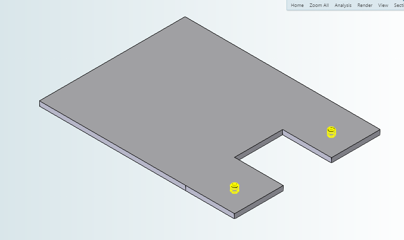

aPriori estimates a part’s manufacturing and material costs to assess how its cost will be affected by rising prices when procuring materials. For instance, the majority of a simple, non-complex part’s cost will lie mainly in the materials rather than the manufacturing (Figure 1). If material sourcing rates double, the piece part cost of this component, or the price the buyer pays the supplier, may also double.

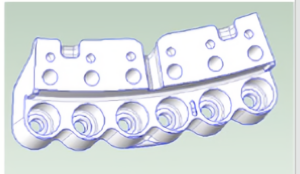

As part complexity intensifies, production costs also typically increase, and manufacturing assumes a larger portion of the overall cost (Figure 2). If material rates double, the piece part cost of this component should not double. The manufacturing cost of the complex part will stay the same regardless of the material rate increase.

aPriori’s detailed, data-driven cost insights give procurement teams full visibility into their parts to ensure that buyers do not pay unreasonable prices for a particular component.

Facilitating Fact-Based Negotiations for Sourcing Experts

The cost engineer can support the team sourcing materials by analyzing and vetting supplier prices early in the product development life cycle. Through aPriori, cost experts have the calculative means to identify discrepancies in supplier prices based on rising material costs. These accurate should cost estimations are shared with sourcing professionals before they even start negotiating with their preferred suppliers.

With accurate part cost estimates in hand, manufacturers can initiate fact-based negotiations with suppliers during the procurement process, reviewing differences between the estimate and their cost breakdowns. These collaborative discussions allow buyers to achieve savings, improve the bottom line, and gain a competitive advantage in today’s challenging environment. Buyers who bring more transparency to negotiations build and further strengthen their partnerships with critical vendors.

See how you can evaluate machined parts’ cost, manufacturability, AND sustainability in this demo.

Are You Maximizing Your Procurement Efforts?

See where you are among 300 manufacturers and suppliers. Learn how to streamline and improve supplier collaboration