How GE Appliances Optimized Its Supply Chain

Key Takeaways:

- Manufacturers are using supply chain insights to optimize supplier relationships and mitigate disruptions

- Proactive manufacturers “don’t let a good crisis go to waste”, capitalizing on it to transform their supply chains

The Full Article:

In the shadow of the past few years’ disruptions, manufacturers are retooling their approach to supply chain management. Rather than reacting to disruptions, manufacturers are focused on optimizing their sourcing capabilities and supplier relationships.

At our recent Manufacturing Insights Conference, aPriori President & CEO Stephanie Feraday and Rob Lidster, former Chief Procurement Officer of GE Appliances, discussed how the company shifted from supply chain reaction to sourcing optimization.

Pinpoint the Most Optimal Suppliers

According to Lidster, GE Appliances became laser-focused in drilling down to better understand the source of all components and raw materials. To see where they could improve sourcing, GE Appliances needed to “map” its network of primary suppliers and secondary vendors further down the value chain.

With aPriori, GE Appliances can run sourcing data through manufacturing insights technology and analyze it to determine the best course of action before it becomes an issue and to pinpoint the most optimal suppliers.

Discover how cost engineering can help navigate global supply chain issues.

Source for Resiliency and Cost

A manufacturing insights solution that enables manufacturers to compare cost savings based on the supplier and their location is invaluable. Although you might be able to save on a part from China, the transportation costs associated with that part – not to mention the carbon footprint – could negate any initial savings. Effective sourcing decisions require companies to understand where the parts and materials are coming from, along with the potential risks, costs, and carbon impact of their procurement strategies.

GE Appliances is moving from a cost-first philosophy to a total cost of ownership (TCO) model throughout the product lifecycle. Identifying the standalone cost of a component is straightforward. GE Appliances is looking beyond initial cost to understand the overall impact of product performance, shipping/logistics, and sustainability.

Lidster said GE Appliances wants to strengthen its value chain analysis. aPriori’s solutions can help them verify if they are on the right track. For instance, aPriori can show them where there may be an overreliance on sourcing from a specific supplier or region and where they might need to tack in another direction.

It also ensures that teams could work simultaneously and collaborate cross-functionally. GE Appliances improved supplier relationships too. In addition to just negotiating supplier costs, which Lidster added GE Appliances was good at, the company is also fostering supplier relationships to accelerate innovation and ensure availability. Nurturing existing supplier relationships aided in this process. Lidster admitted that although they may not always get a piece price reduction, the total value chain landed cost and total cost of ownership are where the greatest impact can be.

“Don’t Let a Good Crisis Go to Waste”

GE Appliances’ engineering teams needed to rethink their approach to product development as well. The mindset has shifted to “Let’s take a variation of an existing part to create a new part fit, form, and function.” This idea echoes Lidster’s advice, “Don’t let a good crisis go to waste.” Take what you’ve done in the past and leverage your current situation to improve upon processes. How do you leverage more of your PLM and parts library to use existing and carryover parts or variants of an existing part versus designing something new? From there, you can raise the design engineer’s cost-consciousness as well.

Lidster doesn’t view costs purely through a savings lens either. He considers the return on that cost to the organization. By using aPriori material, price, and overhead data points as well as those percentages on the selling price, he can ensure margin growth, not just cost savings. He said more C-suite executives are recognizing the integral role sourcing plays in profit margins. Solutions such as aPriori allow sourcing to clearly and compellingly illustrate where they provide value – whether it’s cost-savings, improved supplier relations, or supporting faster time to market.

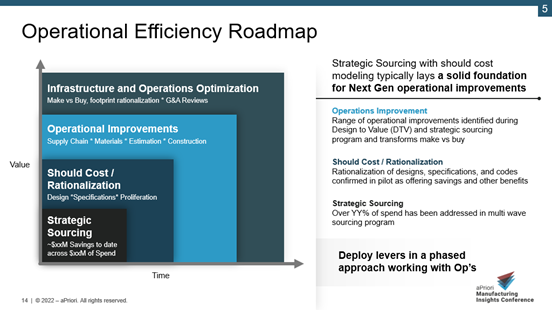

Image 1: GE Appliances Operational Efficiency Roadmap for Sourcing

aPriori as a North Star for Strategies and Processes

aPriori can serve as a North Star for sourcing, providing important data and facilitating analysis of that information for better decision-making. Lidster added that GE Appliances employs a product architecture or part optimization/rationalization methodology. “In our programs, we started to measure and then communicate progress to senior leadership,” said Lidster. He explained that they can detail the number of new parts, carryover parts, and the number that are modified. Then they can examine the new parts, determining which are necessary. Lidster confirmed the importance of the centralized should-costing organization. He recounted that a should-cost engineer would say, “I’ve already costed a motor, very similar to that one. The only thing that’s changing is the shaft length. Why do we need to change the shaft length? Do I have a parts library?”

aPriori supports revisiting parts necessity. It helps should cost engineers better understand what is similar and currently available versus what is being newly designed or costed from the ground up.

An Optimized Supply Chain for Greater Profitability and Time to Market

A McKinsey survey found that more companies are implementing supply chain optimization strategies. It found that 81% had dual-sourcing strategies in 2021-2022. Forty-four percent, up from 25% in 2021, were developing regionalized supply networks.

A manufacturing insights solution like aPriori can help boost sourcing optimization. Manufacturers will create a stronger supply chain and become more collaborative, innovative, and competitive across the product development lifecycle.

Supply Chains Impeding Production?

Leverage digital factories to improve supplier information and access