aPriori 22.1 Expands Manufacturing Insights & Cost Savings Analysis

aPriori works closely with our customers and other manufacturing leaders to develop new capabilities that address critical pain points. And our new 22.1 release provides manufacturers and suppliers with new levels of speed, agility, and insights to plan confidently and profitably amid uncertainty.

The aPriori 22.1 release expands our Manufacturing Insights Platform, which delivers insights for manufacturers to optimize product design, manufacturing process, and select manufacturing locations to increase cash flow, revenues, and margin. Through collaboration and automation, the aPriori Manufacturing Insights Platform connects design engineers, cost engineers, sourcing/procurement teams, and supply chain teams.

aPriori’s 22.1 manufacturing advancements include:

- New manufacturing process models (440 and counting!)

- New design guidance for SMC compression molding and bar & tube fabrication

- Enhanced design guidance and reporting

- Automated workflows for product development teams

- Granular labor rate and material pricing data

1. New Manufacturing Process Models (440 and Counting!)

aPriori leads the industry with more than 440 manufacturing process models. Our mechanistic costing engine provides precise cycle times and operational costs across a range of manufacturing alternatives. Customers use aPriori’s insights to compare manufacturing processes and optimize production for specific project specifications.

With release 22.1, aPriori now provides manufacturing process models for sheet metal roll forming and sheet molding compound (SMC) compression molding. aPriori continues to expand the breadth and depth of its manufacturing cost models, which include additive, composite, PCBA, plastic molding, and wire harness.

Sheet Metal Roll Forming: New Manufacturing Process Model

Manufacturing brands in aerospace, automotive, power & energy, and industrial markets use sheet metal roll forming for high-volume production with close tolerances. aPriori analyzes the following to assess cycle/production time and calculate costs:

- Cycle time and process cost are determined by calculating the slowest process in the line

- Tool cost evaluation includes:

- The number and size of roll dies and roll material

- Tooling for punch and cutoff presses

- Material utilization considers holes and cutouts, and slugs produced by the cutoff die

SMC Compression Molding: New Manufacturing Process Model

SMC is molded to create automotive body panels and other components/parts. It is a lightweight, high-strength composite material often used as an alternative to heavier sheet metal manufacturing. aPriori determines the most effective process routing, cycle time, and cost based on the following analysis:

- Preparation (loading, pressing, and unloading)

- Parallel operations such as manual flash trimming

- Offline trimming, treatments, and secondary processes

2. New Design Guidance for SMC Compression Molding and Bar & Tube Fabrication

aPriori now provides design guidance for 11 process groups – from plastic molding and casting to turning. Customers use aPriori’s design guidance to optimize products for manufacturability and cost. This includes using real-world factory data and manufacturing process insights to conduct trade-off analysis and meet objectives for cost, performance, etc. New design guidance includes:

- SMC Compression Molding: aPriori automatically identifies potential cost and manufacturability issues – including requirements for additional press force, high variations in thickness, and the need for secondary machining during production.

- Bar & Tube Fabrication: aPriori pinpoints key DFM issues to reduce tooling complexity, tooling production time, and specialized tooling requirements. And aPriori also provides guidance to maintain high design integrity (e.g., avoid thinning or tearing of material, prevent wrinkling or distortion).

3. Enhanced Design Guidance and Reporting

Usability becomes even more important as we introduce new features and build out existing capabilities. And we continue to refine our interfaces and processes to make it easier for our users to manage increasingly complex product design requirements.

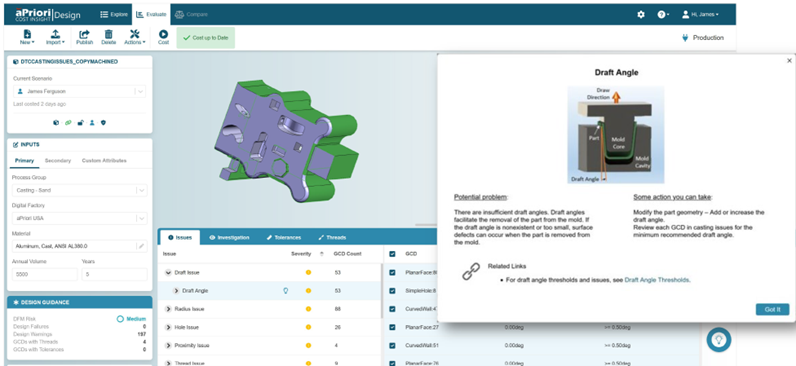

As an example, the new aPriori Design interface makes it easier for users to see design for manufacturing (DFM) guidance as they scroll through issues (see Figure 1). We’re also now categorizing issues to better reflect product design team roles and responsibilities. aPriori now segments issues by design for manufacture and design to cost (DTC). Users can also sort issues by severity to help prioritize their work.

In addition to simplifying how users view design guidance, aPriori now provides insights for 11 process groups. In 22.1, aPriori introduced new design guidance for SMC compression molding and bar & tube fabrication.

Automated Cost Avoidance/Value Tracking Reports

aPriori’s new out-of-the-box value tracking report provides a robust view of cost avoidance achievements. This report can automatically track cost savings by multiple key performance indicators (KPIs) – including cost avoidance per individual component, a set of components or assemblies, and annualized cost avoidance.

Users can create high-level reports for senior management and detailed insights for product development teams. To capture cost savings, aPriori automatically calculates the difference between the highest costs and the latest costs of components/assemblies analyzed. Users can create aPriori reports based on fully burdened costs, total variable costs, and other criteria.

4. Automated Workflows for Product Development Teams

aPriori continues to expand workflow capabilities to keep fast-moving product development teams in sync and up-to-date. The aPriori workflows connect design engineers, cost engineers, and sourcing/procurement managers.

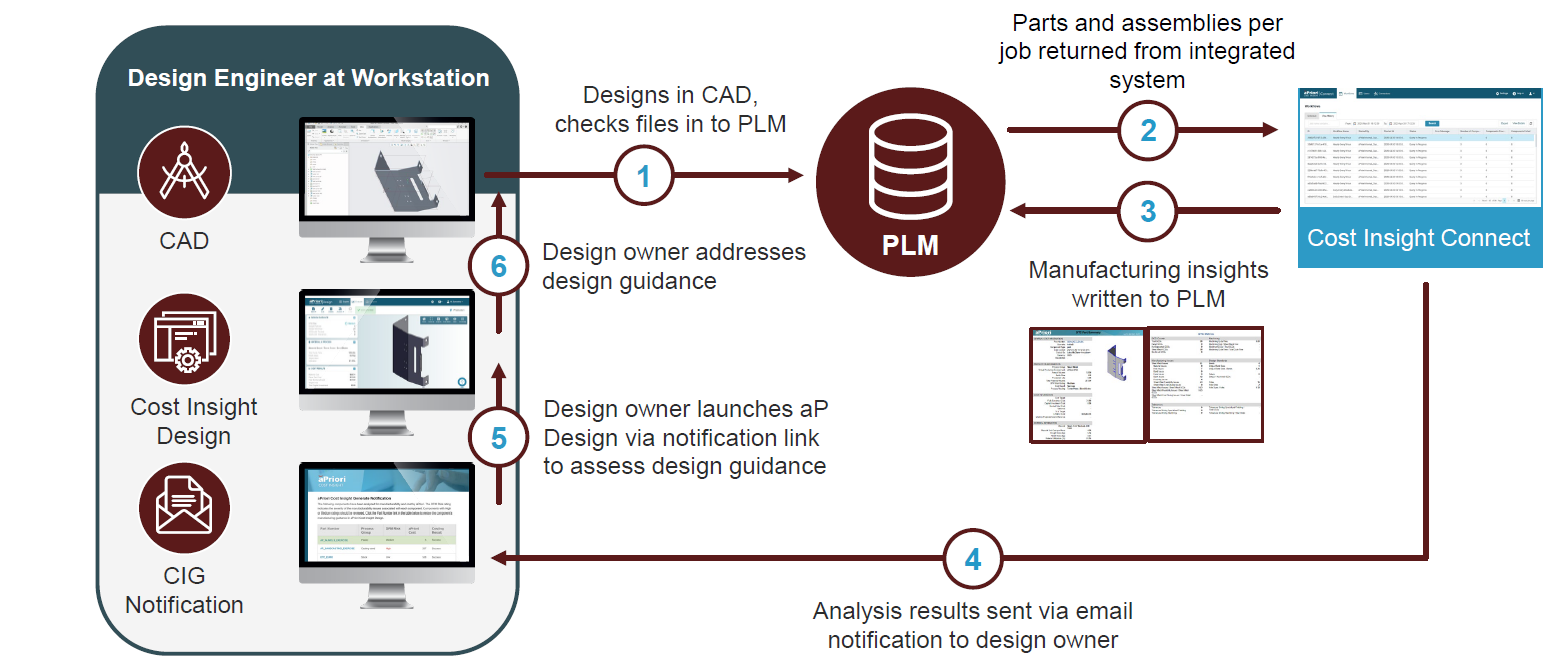

For one example, automation begins once a design engineer checks in CAD design changes – parts and assemblies – into a PLM system. aProri automatically adds CAD file manufacturing insights to the PLM system. And aPriori also notifies the design owner of CAD changes via email (e.g., the mechanical engineering project manager). The design owner clicks email links to each proposed design change, reviews guidance, and determines next steps (see Figure 3).

Additional aPriori workflows streamline collaboration between cost engineering and sourcing.

5. Granular Labor Rate and Material Pricing Data

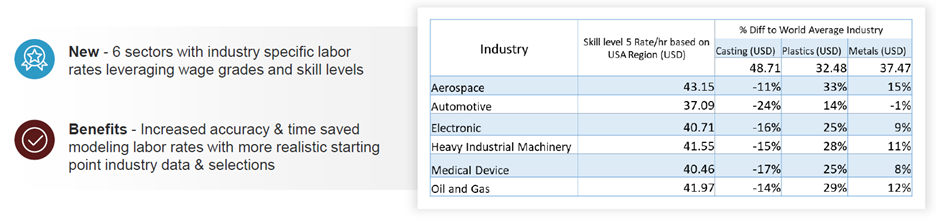

aPriori Regional Data Libraries (RDLs) provide cost insights by geography – including labor, overhead, and tool shop rates. Our 87 RDLs provide sourcing teams with costing assumptions based on relevant global market information.

aPriori is now also providing additional labor rate specificity by industry. aPriori determined labor rates in the following six industries based on wage grades and skill levels:

- Aerospace

- Automotive

- Electronic

- Heavy Industrial Machinery

- Medical Devices

- Oil & Gas

aPriori is also now providing regional pricing for commodities to improve costing accuracy and help to accelerate planning based on regional manufacturing scenarios. We now breakout commodity prices by the following geographies:

- Asia

- Europe

- World average

Even More Enhancements

aPriori release 22.1 includes additional enhancements that we don’t have room to spotlight here. Our Manufacturing Insights Platform includes new time-saving features, tighter integration with industry-leading CAD applications, and additional design enhancements based on user feedback. Additionally, we’ve rolled out manufacturing process models for casting and rough milling.

aPriori also continues to expand features for its cloud platform. New capabilities include multi-file and assembly upload capability, automated extraction of Creo welds, and user interface and design enhancements.

Learn more about aPriori’s 22.1 enhancements

Watch our 22.1 update webinar to learn more about our latest features.