Press Release

August 3, 2022aPriori Release 22.1 Expands Manufacturing Insights to Accelerate Growth, Cash Flow, and Mitigate Risk

CONCORD, MASS. – aPriori today announced the 22.1 release of its Manufacturing Insights Platform, which provides manufacturers and suppliers with new levels of speed, agility, and intelligence to plan confidently and profitably amid market uncertainty.

aPriori release 22.1 provides manufacturers with insights to optimize product design, manufacturing processes, and select optimal manufacturing locations to increase cash flow, revenues, and margin. Through collaboration and automation, the aPriori Manufacturing Insights Platform connects design engineers, cost engineers, sourcing/procurement teams, and supply chain teams.

“aPriori works closely with our customers and other manufacturing leaders to understand how market shifts are creating new requirements. Our aPriori 22.1 release provides new capabilities to streamline operations and gain insights to make business decisions quickly and confidently,” said Fielder Hiss, Chief Product Officer, aPriori. “Customers are applying aPriori insights to address critical business challenges such as inflation, cash flow, and supply chain risk.”

In release 22.1, aPriori expands its design for manufacturability (DFM) guidance, streamlines processes, and automates reports and workflows. Key features include:

New Manufacturing Process Models

aPriori leads the industry with more than 440 manufacturing process models. Our mechanistic analysis engine provides precise cycle times and operational costs across a range of manufacturing alternatives. Customers use aPriori to compare manufacturing processes and optimize production for specific project specifications. aPriori’s new manufacturing process model capabilities include:

- Sheet Metal Roll Forming (New): aPriori assesses cycle/production time and calculates costs based on the manufacturing process, tooling, and material utilization.

- Sheet Molding Compound (SMC) Compression Molding (New): aPriori determines the most effective process routing, cycle time, and cost based on preparation (loading, pressing, and unloading), parallel operations, and offline operations (e.g., trimming, treatments, and secondary processes).

- Casting Enhancements: aPriori now provides added accuracy for die casting and sand casting. aPriori’s analysis engine now determines if a design (CAD) cost driver is manufactured via a cast, a machine, or a combination of both. This provides greater visibility into manufacturing time and resource requirements.

- Rough Milling Enhancements: aPriori has added a new level of precision to estimate rough milling across all process groups. aPriori now identifies more areas as pockets, which increases the fidelity of cycle-time estimates. Incorporating pocket analysis also makes it easier to compare multiple process options (e.g., fully machined casting vs. machined casting/forging methods).

New Design Guidance for SMC Compression Molding and Bar & Tube Fabrication

aPriori now provides design guidance for 11 process groups – from plastic molding and casting to turning. Customers use aPriori’s design guidance to optimize products for manufacturability and cost. This includes using real-world factory data and manufacturing process insights to conduct trade-off analysis and meet objectives for cost, performance, etc. New design guidance includes:

- SMC Compression Molding: aPriori automatically identifies potential cost and manufacturability issues – including requirements for additional press force, high variations in thickness, and the need for secondary machining during production.

- Bar & Tube Fabrication: aPriori pinpoints key DFM issues to reduce tooling complexity, tooling production time, and specialized tooling requirements. And aPriori also provides guidance to maintain high design integrity (e.g., avoid thinning or tearing of material, prevent wrinkling or distortion).

Enhanced Usability, Reporting, and Automation

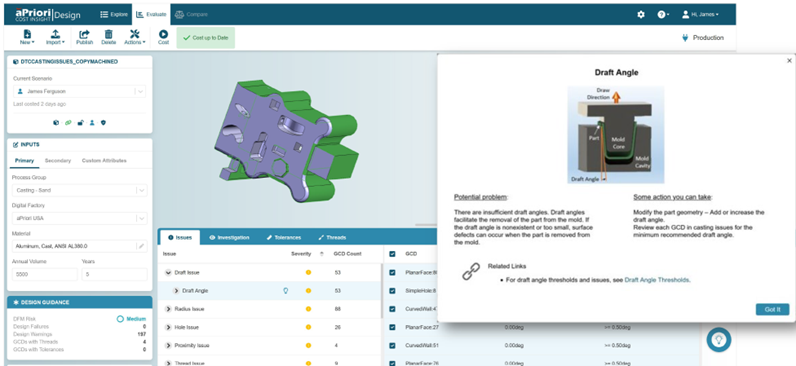

Usability becomes even more important as we introduce features and expand existing capabilities. The new aPriori design interface makes it easier to access DFM guidance (see Figure 1). And to help users view issues by job function, aPriori also segments issues by design for manufacture and design to cost (DTC) categories.

Figure 1: Intuitive Design Guidance

Additionally, aPriori’s new out-of-the-box value tracking report provides a robust view of cost avoidance achievements. aPriori’s automated reports can track cost avoidance per component, by a set of components, and annualized views.

aPriori also continues to expand workflow capabilities to keep fast-moving product development teams in sync and up-to-date. New automated workflows for entire assemblies simplify collaboration among design engineers, cost engineers, and sourcing/procurement managers. And automated alerts help team members prioritize their activities efficiently.

Granular Labor Rate and Material Pricing Data

aPriori Regional Data Libraries (RDLs) provide cost data by geography – including labor, overhead, and tool shop rates. Our 87 RDLs provide sourcing teams with costing assumptions based on current global market information.

Additionally, aPriori is now also providing additional labor rate specificity by industry. aPriori determined labor rates in the following six industries based on wage grades and skill levels:

- Aerospace

- Automotive

- Electronic

- Heavy industrial machinery

- Medical devices

- Oil & gas

aPriori Cloud Enhancements

aPriori also continues to expand features for its cloud platform. New capabilities include:

- Multi-file and assembly upload capability: Users can now upload up to 20 files simultaneously, upload native format assemblies, and specify a new scenario name either individually or for a defined set

- Automated extraction of PTC Creo welds: In addition to automated extraction, this feature also provides it provides FBC and cycle time breakdowns for welding. aPriori users can also manipulate a scenario to re-cost welds.

About aPriori

aPriori is the leading provider of digital manufacturing simulation software that brings product design and sourcing teams closer to production. By leveraging the digital twin within our digital factories, we automatically generate manufacturing intelligence that helps manufacturers collaborate across the product development process to make better design, sourcing, and manufacturing decisions that yield higher-value products in less time. aPriori solutions are now available in the cloud or on-premise. Headquartered in Concord, Mass., aPriori also has offices in Belfast, Northern Ireland and in Munich, Germany. To learn more about aPriori, visit www.apriori.com.

CONTACT:

Alex Wallace

Associate Director of Public Relations

aPriori

awallace@apriori.com

978.451.7687

aPriori and aPriori Technologies are registered trademarks of aPriori Technologies Inc. All other trademarks, registered trademarks, or service marks belong to their respective holders.