Unlock Critical Manufacturing Insights with Digital Factories

Today’s manufacturers have a host of issues to tackle. Sustainability, profitability, and manufacturability are all top priorities. In an ideal world, manufacturers could connect these three together to ensure that products meet sustainability initiatives, achieve profitability targets, and are designed and manufactured in ways that mitigate risk. Digital factories that provide multiple manufacturing insights simultaneously can do just that.

In this article, we tackle the following questions: How can you successfully ensure a high-value product and integrate sustainability initiatives while keeping costs in check? How can you find the sweet spot to lower your carbon footprint and reduce cost? What tools can facilitate a more streamlined approach to understand the most critical insights for manufacturability, feasibility, cost, and sustainability?

How a Digital Factory Helps Manufacturers

Manufacturers are looking for new ways to tackle pressing priorities. A digital factory can facilitate this objective. A digital factory is a digital representation of a physical factory. It has the key elements you would find if you walked into any production facility, including thousands of different machines and types of materials as well as labor and overhead costs – all that you’d find with a physical factory.

Digital factories provide manufacturability analysis and costing feedback, helping design engineers to design for manufacturing (DFM), reduce change orders (ECOs) and get products to market faster. Sourcing teams also use digital factories to compare production environments across extensive manufacturing criteria to inform site selection and manufacturing costs. Digital factories can identify and select less expensive raw materials, cheaper manufacturing processes that offer faster cycle times, and alternative finishing options.

aPriori’s seamless digital factories unlock those manufacturability, feasibility, cost, and sustainability insights. As a result, manufacturers can:

- Meet profitability goals with cost breakdowns to identify outliers and mitigate inflation and margin pressure.

- Lower supply chain risks with design guidance that offers design recommendations that can compensate for labor and skills gaps, reduce supply chain risks, and push sustainability initiatives forward.

- Give engineers knowledge to create higher value products via manufacturing feasibility to determine the practicality of making a product which might prove too costly or impossible to manufacture.

- Meet customers’ product needs and desire for more sustainable products by providing a CO2e footprint breakdown to analyze and implement sustainability actions.

Regardless of the challenges they face throughout the product lifecycle, they will be able to tackle them with agility and proficiency.

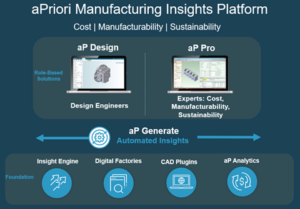

Identify the best tool to help you gain critical insights for manufacturability, feasibility, cost, and sustainability.

By simulating manufacturing with aPriori’s digital factories, manufacturers will be able to meet the following:

Design for Manufacturing (DFM): Demands for more customization and faster time to market require new and better ways to improve production and product quality.

aPriori will automate, streamline, and optimize DFM processes via early visibility feedback. aPriori technology offers access to regional sourcing libraries and customized dashboard reporting. Manufacturers can pinpoint manufacturability-driven cost-reduction opportunities. Manufacturability issues and cost overruns can more easily and quickly be identified and remedied.

Manufacturing Feasibility: In tandem with DFM is manufacturing feasibility. Its rules are part of aPriori’s manufacturing process model logic, supporting process viability assessments as well as analyzing the machines within processes. Rules vary according to the process.

A major aspect of the process models’ intelligence is automated analysis. Although checks on their own are helpful, they are only part of the story. Feasibility rules are important when executing cost/value trade-offs of design options. It is also impactful when generating should costs. These manufacturing details can help a cost engineer or buyer make sourcing decisions. For instance, it will be helpful for them to understand tolerance impacts since they could require additional processes and significant cost. It also can help determine whether material thickness and part size can be evaluated when selecting the appropriate tonnage machine or if a material is suitable to a specific manufacturing process.

Design for Cost: You can lower your manufacturing costs, but if supply chain delays increase them, you will not be profitable in the long run. A robust manufacturing insights platform, such as aPriori, will provide automated analysis with design feedback to reduce costs. Using aPriori, manufacturers will be able to identify cost outliers that can be eliminated with an early redesign.

Design for Sustainability: Regulations and greater social awareness are placing more pressure on manufacturers to implement sustainability initiatives. 80% of a product’s early design determines its environmental impact. Manufacturers can utilize automated geometry-driven analysis of 3D CAD data to evaluate their CO2 footprint. Additionally, they can analyze complete and tailored environmental and cost data with granular, traceable, and transparent calculations. Finally, they can evaluate CO2 in comparison to cost to ensure both sustainability AND profitability.

The Benefits of Unlocking Manufacturing Insights

Today’s environment requires manufacturers to create high-value products faster with fewer resources yet higher profit margins. To add to the pressure, they must make a concerted effort to minimize their environmental impact.

Though it seems like a tall order, it is doable with the right manufacturing insights technology. Moreover, many of aPriori’s customers see immediate and positive impacts, including:

- Mitigate inflation and other risks that cut into profits. At the current churn rate, about half of today’s S&P 500 firms will be replaced over the next 10 years. Instead, manufacturers can increase margins on legacy products and generate new product revenue growth. Consequently, they will remain competitive and agile in the marketplace.

- Circumvent supply chain issues once and for all. Manufacturing insights allow enterprises to take a proactive approach to the issues that disrupt the supply chain and slow production for manufacturers. According to McKinsey, even a short disruption of 30 days or less can put 3 to 5 percent of the EBITDA margin at risk. aPriori’s Regional Data Libraries give manufacturers insight into supplier costs and availability in 87 regions throughout the world. This data also helps sourcing and procurement negotiate more effectively and keep costs down.

- Close labor and skills gaps: According to Forbes, 57% of manufacturers surveyed say students have been prepared for CAD. However, 65% indicate students are not well prepared to create designs that are manufacturable. Manufacturing insights help train and upskill newer design engineers as well as compensate for labor shortages by automating processes that require less knowledge and skill. It can identify critical data to help drive better designs, lower costs, and support sustainability initiatives.

- Drive sustainability initiatives to completion: Bain & Company noted that just 4% of sustainability initiatives fully succeed. Manufacturing insights can evaluate a manufacturer’s CO2 footprint. Then it can provide a customized, comprehensive analysis of its environmental and cost impacts, providing recommendations to reduce their CO2 footprint while keeping costs in line.

Conclusion

Manufacturers have a lot to contend with today. However, they can overcome these issues and still achieve their manufacturability, feasibility, cost, and sustainability goals by implementing the right technology.

Your platform should deliver strategic insights, providing effective recommendations. It should determine the best product designs, optimize cash flow, reduce costs, improve profitability and revenue growth, and decrease the carbon footprint. As a result, manufacturers can enhance the entire product lifecycle, from design to production.

Harness the power of manufacturing insights

Overcome challenges. Meet manufacturability, feasibility, cost, and sustainability goals.