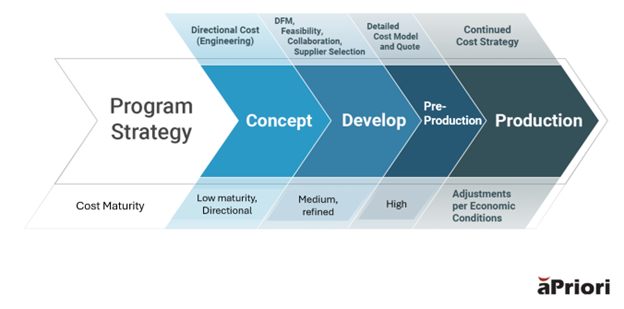

The Progression of Cost Maturity in Product Development

Key Takeaways:

- Cost-matured companies consider costs earlier in product development, specifically in the early design stage

- Cost maturity in product development increases with each progressive stage

- aPriori provides a comprehensive platform that focuses on early, accurate cost estimation, manufacturability analysis, and collaboration across various teams

The Full Article

Though statistics vary, based on empirical evidence, new product introductions fail at a rate of approximately 40% within two years after launch.

Cost maturity in product development significantly impacts new product introduction (NPI) failure rates by addressing key failure drivers early in the process. When a company demonstrates cost maturity in product development, it means it is not just reacting to cost overruns but proactively managing and optimizing costs from the initial ideation and design phases through launch and beyond.

What Is Cost Maturity in Product Development?

Cost maturity in product development refers to an organization’s ability to estimate, track, control, and optimize costs. It evolves and improves as a new product moves from initial concept to target market.

If executed successfully, manufacturers can achieve greater predictability, efficiency, and effectiveness in cost management at each stage of the product lifecycle:

- From Reactive to Proactive: As maturity increases, organizations move from reacting to cost overruns to proactively managing and influencing costs from the earliest stages.

- Increasing Accuracy & Predictability: Due to better data, refined processes, and experience, cost estimates become more precise and reliable over time.

- Integration and Collaboration: Cost management becomes less siloed and more integrated across different functions.

- Data-Driven Decision-Making: Mature organizations leverage data and analytics to inform cost decisions and identify optimization opportunities.

- Cost Conscious Culture: A high level of cost maturity is often accompanied by a culture where all employees understand and contribute to cost management.

By understanding and actively managing the cost maturity process, companies can significantly improve their product profitability, competitiveness, and overall business success.

The Progression of Cost Maturity In Product Development

Here’s a breakdown of the cost maturity process throughout product development, often aligned with product lifecycle stages:

- Ideation/Concept Stage (Low Cost Maturity): This is the earliest stage, where ideas are generated, and initial feasibility is assessed. Cost estimates are highly uncertain, often broad strokes or “back-of-the-envelope” figures.

- Cost Focus:

- Rough estimations: Understanding the potential investment magnitude is required.

- High-level cost drivers: Identifying major components, technologies, and potential manufacturing methods that will influence cost.

- Go/No-Go decisions: Determining if the concept is financially viable enough to proceed to the next stage.

- Cost Management: There is minimal formal tracking; instead, the focus is on conceptualizing and exploring options rather than detailed cost control.

- Design and Development Stage (Developing Cost Maturity): Detailed design, engineering, and prototyping occur. As specifications are finalized, costs become more defined. This is a critical stage where a significant portion of the product’s total life cycle cost is committed (often 80% or more).

- Cost Focus:

- Detailed Cost Estimation: Moving from broad product cost estimates to more specific ones for raw materials, labor, tooling, engineering, and testing.

- Target Costing/Design-to-Cost: Increasingly, organizations employ methodologies like target costing (setting a target selling price and then working backward to define allowable costs) or design-to-cost (treating cost as a design parameter from the outset). This is crucial for influencing manufacturing costs when it’s most impactful.

- Prototyping: Managing the costs associated with multiple prototype iterations.

- Vendor Selection: Researching and negotiating with potential suppliers for components and manufacturing services.

- Cost Management: More structured tracking of actual costs against estimates. Regular reviews to identify deviations and implement corrective actions. Value engineering might be applied to optimize designs for cost.

- Production/Manufacturing Stage (Maturing Cost Maturity): The product goes into full-scale production. Manufacturing processes are refined, and supply chains are established.

- Cost Focus:

- Production Cost Control: Closely monitoring material costs, labor efficiency, manufacturing overheads, and quality control expenses.

- Economies of Scale: Leveraging larger production volumes to achieve lower per-unit costs.

- Supply Chain Optimization: Continuously seeking ways to improve efficiency and reduce costs within the supply chain.

- Quality: Managing costs associated with defects, rework, and warranty claims.

- Cost Management: Robust cost accounting systems are in place. Variance analysis compares actual costs to standard costs to identify areas for improvement. Continuous improvement initiatives like lean manufacturing can significantly impact costs.

- Introduction Stage/Growth Stage (High Cost Maturity—Operational Focus): The product is launched into the market. Sales gain momentum, and the organization establishes market share. With development costs largely in the rearview mirror, costs related to marketing, distribution, and customer support emerge.

- Cost Focus:

- Marketing & Sales: Managing promotional expenses (such as marketing campaigns), sales force costs, and distribution channels.

- Customer Service: Establishing and managing support infrastructure.

- Logistics: Optimizing shipping and warehousing.

- Profitability Analysis: Understanding the product’s profitability as sales increase and initial development costs are amortized.

- Cost Management: Focus shifts to optimizing operational efficiency and maximizing revenue to cover costs and generate profit. Performance metrics related to product sales, marketing ROI, and customer acquisition cost become important.

- Maturity Stage (Optimized Cost Maturity): Sales stabilize and peak. Competition is often intense. The focus is on maintaining market share and maximizing profitability.

- Cost Focus:

- Cost Reduction Initiatives: Continuous efforts to identify and implement cost-saving measures in production, distribution, and even marketing efforts (e.g., streamlining product launch campaigns).

- Process Optimization: Refining all operational processes to remove waste and improve efficiency.

- Value Engineering (revisited): Looking for opportunities to reduce costs while maintaining or enhancing the customer base value.

- Product Line Extension: Managing costs for minor product variations or updates to extend the product’s life.

- Cost Management: Highly mature cost management practices, often leveraging advanced analytics, benchmarking, and cross-functional teams to drive continuous cost improvement.

- Decline Stage (Strategic Cost Maturity): Sales and profits decline as the product becomes obsolete or is replaced by newer alternatives.

- Cost Focus:

- Minimizing Losses: Reducing production and marketing costs to minimize losses.

- Inventory Management: Liquidating excess inventory efficiently.

- Product End-of-Life: Disposal, recycling, or decommissioning costs.

- Resource Reallocation: Shifting resources to new, more promising products.

- Cost Management: Strategic decisions are made regarding product discontinuation, divestment, or revitalization efforts. Cost control is focused on minimizing the negative financial impact.

aPriori’s Role in Product Development Cost Maturity

aPriori plays a significant role in improving cost maturity in product development. aPriori provides a comprehensive platform that focuses on early, accurate cost estimation, manufacturability analysis, and collaboration across various teams.

Let’s look more closely at how aPriori contributes to each level of cost maturity:

Transitioning From Ad Hoc Or Basic Cost Management To A Structured Plan, Including:

- Automated Cost Estimation: Automation removes informal, inconsistent, and reactive cost management (Level 1: Ad Hoc) and limited, non-integrated processes (Level 2: Basic). By using 3D CAD models, aPriori automatically generates precise “should-cost” estimates. This eliminates reliance on manual spreadsheets and subjective assumptions, providing a consistent and accurate baseline for cost.

- Digital Factories: aPriori’s digital factories are configured with regional data libraries (RDLs), machine rates, labor costs, material prices, and manufacturing processes. This allows for rapid and precise production simulation, even for complex geometries, leading to more reliable cost targets.

- Early Identification of Cost Drivers: aPriori helps identify cost drivers and manufacturability issues early in the design phase. This is crucial because making late-stage product development changes is significantly more expensive. By highlighting potential issues, it encourages “Design for Manufacturability (DFM)” and “Design to Cost (DTC)” principles.

Achieving Integrated and Optimized Cost Management:

- Cross-Functional Collaboration: aPriori facilitates seamless collaboration between engineering, design, sourcing, and manufacturing teams. Teams can share insights, manage tasks, and communicate about cost and manufacturability directly on 3D CAD components. As a result, silos are removed and a shared understanding of cost implications across the product lifecycle is fostered.

- “What-If” Scenario Analysis: Conducting “what-if” scenarios (e.g., changing materials, manufacturing processes, regions, suppliers, volumes) enables teams to explore cost-saving opportunities. It also optimizes product designs before committing to production. More informed decisions then maximize profitability.

- Supplier Collaboration and Negotiation: aPriori provides detailed cost breakdowns, empowering sourcing and procurement teams with factual data for negotiating better terms with suppliers. It allows for “make vs. buy” analysis and helps identify cost outliers, leading to more transparent and effective supplier relationships.

- Integration with PLM, CAD, and ERP: By integrating with existing enterprise systems like PLM, aPriori streamlines workflows and ensures that cost, manufacturability, and sustainability data are consistently updated and accessible across the organization. This creates a “single source of truth” for product data.

- Continuous Improvement: The data generated by aPriori builds historically, providing valuable insights for continuous monitoring and improvement of cost management processes. This supports the highest levels of cost maturity (Level 4: Integrated, and Level 5: Optimized), where cost management is continuously refined and drives strategic decision-making.

Less Reactive, More Proactive Cost Maturity in Product Development

aPriori’s technology can have a profound impact on cost maturity in product development. By shifting from reactive cost control to proactive cost management with real-time, data-driven insights, manufacturers can gain an understanding of the true economic cost of a product from its earliest stages.

As a result, they can reduce late-stage engineering changes, accelerate time-to-market, and significantly improve profitability.

Check back next month. We will outline why cost as a KPI can foster a cost-conscious culture and boost profitability across the entire organization.

How Accurate Are Your Product Cost Projections?

See how simulation-driven analysis connects design decisions with key cost drivers, empowering you to identify savings opportunities and streamline supplier negotiations.