Navigating 2025 Manufacturing Tariffs: Strategic Sourcing Made Simple

Key Takeaways:

- Potential manufacturing tariffs could significantly impact operations and profits

- AI-driven sourcing insights can help mitigate the financial impact of tariffs and help manufacturers navigate a more unpredictable supply chain

The Full Article:

A New Era of Supply Chain Complexity

In 2025, manufacturers face a seismic shift in global trade dynamics. The prospect of a 60% tariff on Chinese imports, along with a 10%-25% tariff on goods from most other countries, threatens to upend supply chains worldwide.

During the Trump administration’s first presidency, many companies mitigated manufacturing tariff risks by shifting production and sourcing to regions like Vietnam and Mexico. However, this time, the scale and scope of the changes demand an even more sophisticated approach.

For supply chain and sourcing professionals, this is not just a challenge—it’s an opportunity to embrace advanced tools and data-driven strategies. Tools like aPriori are poised to play a pivotal role, empowering teams to identify risks, explore alternatives, and make strategic decisions that minimize costs and disruptions.

How aPriori Empowers Sourcing Teams

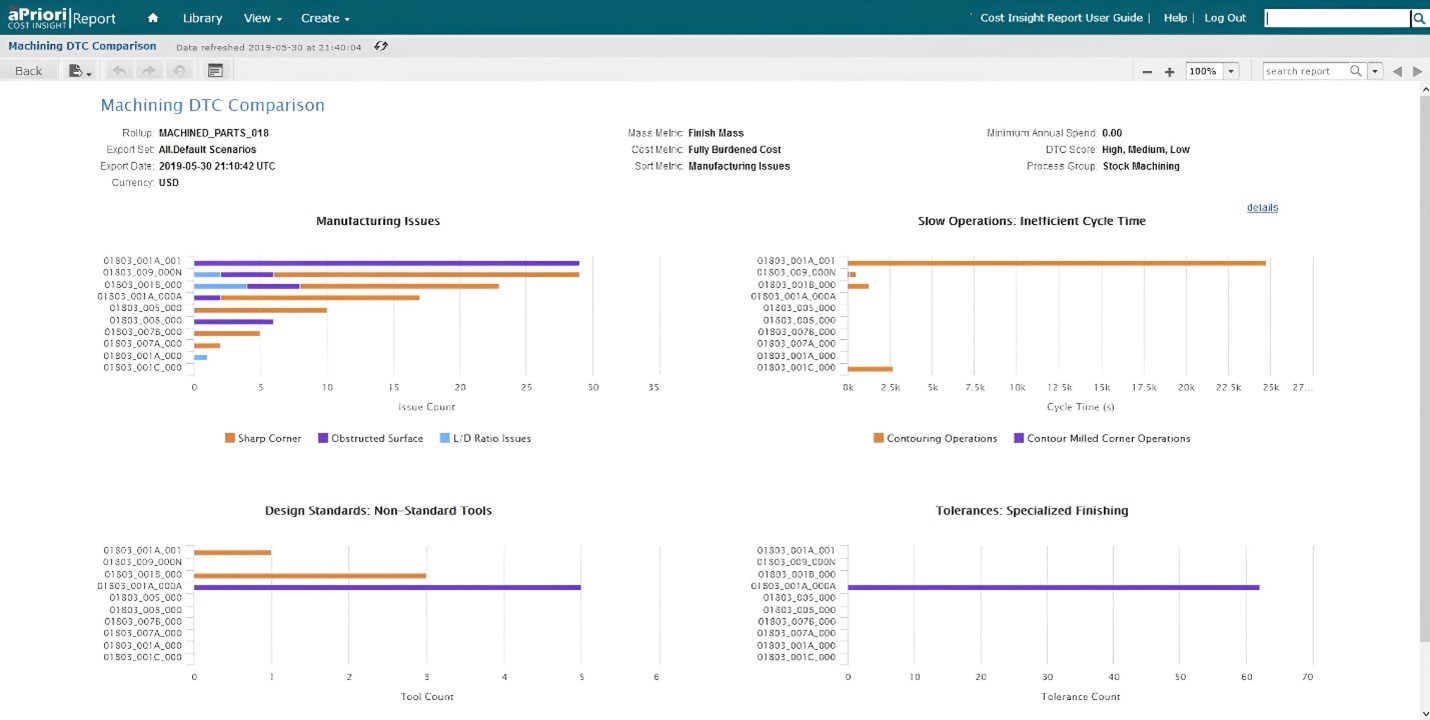

To navigate the complexities of the new tariff landscape, sourcing teams need granular insights into material usage, product cost structures, and alternative sourcing options. Here’s a step-by-step example of how aPriori can help sourcing teams respond effectively:

Example Scenario: Managing the Impact of Aluminum Tariffs

Step 1: Identify the Affected Material

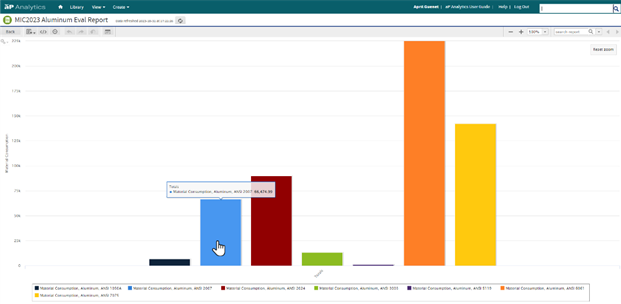

Using aPriori’s Material Consumption Report, the sourcing team identifies aluminum as a critical material imported from China, subject to the 60% tariff.

- Insight: The report shows that aluminum accounts for 20% of total material costs across various products.

Step 2: Quantify Material Usage

aPriori analyzes the amount of aluminum used across the company’s product lines, highlighting the specific components that rely on it.

- Insight: Aluminum usage is concentrated in 15 components across three major product categories.

Step 3: Assess the Impact on Products

aPriori quantifies the financial impact of the manufacturing tariff on each affected component and the overall product cost.

- Insight: For one key product line, the tariff increases costs by 18%, threatening profitability.

Step 4: Collaborate on Mitigation Strategies

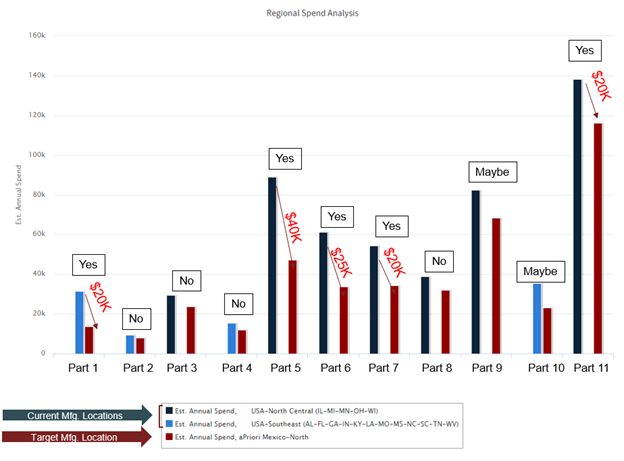

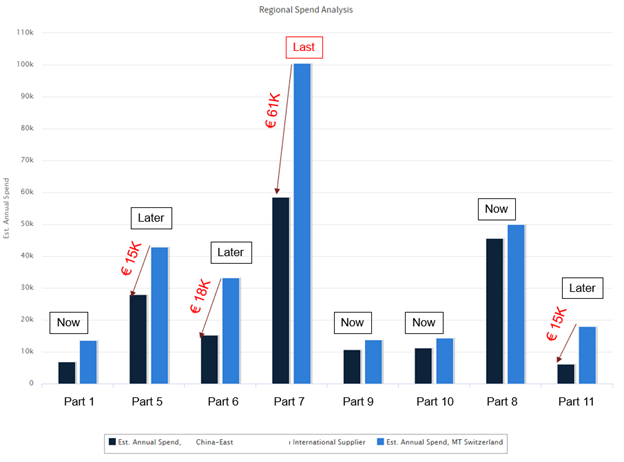

The sourcing and engineering teams collaborate to categorize components into three buckets:

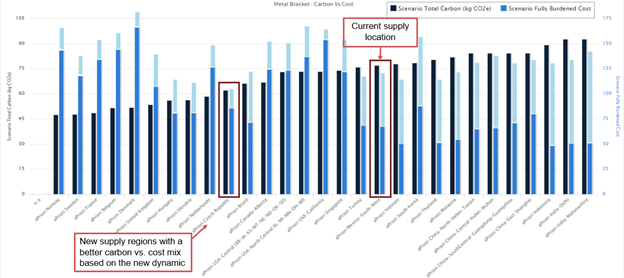

- Move to Alternative Locations:

- For example, shifting production of aluminum parts to Mexico to leverage lower labor costs and avoid the 60% tariff.

-

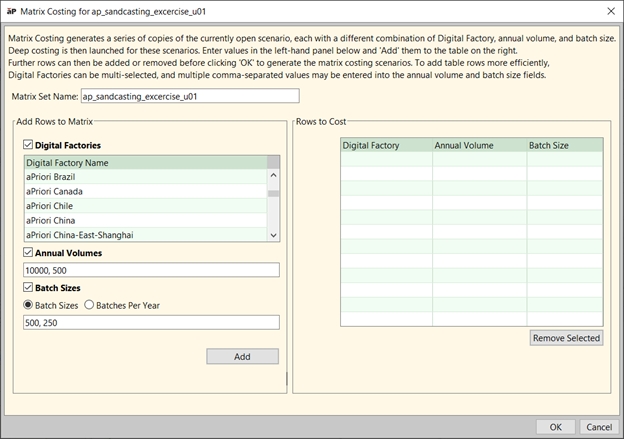

- Tool: aPriori’s Matrix Analysis simulates costs in different locations, including override assumptions to account for the 25% tariff in Mexico.

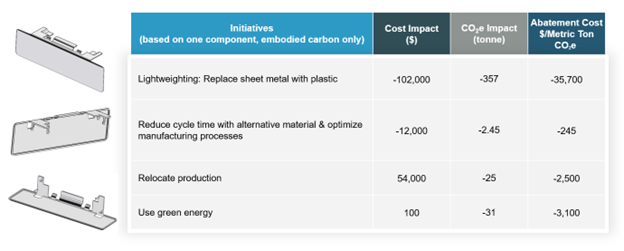

- Design Differently:

- Exploring alternative materials or modifying the design to consume less Aluminum

- Tool: aPriori compares the costs of new materials and their impact on manufacturing processes, as well as comparing the cost of new design concepts

- Prioritize Transfer of Parts:

- Clearly identify which components will have the least economic impact or the most to gain from relocation, and which will cost much more helping you prioritize the order in which you will transfer the parts/components

- Alternatively, evaluate skilled labor needed to make the components and prioritize relocating the parts with lower risk of finding suppliers with the necessary skill sets

For example: an assembly requires a large amount of manual welding, or a part requires a lot of CNC machining time

- Insight: For one high-volume component, absorbing the manufacturing tariff cost is viable due to strong customer sales and profitability margins.

Essential Insight: Mitigating Risk with aPriori

In a rapidly changing global trade environment, manufacturers must act swiftly and strategically to mitigate risks posed by manufacturing tariffs, material availability, and supply chain disruptions. aPriori provides sourcing and supply chain teams with the tools they need to:

- Identify material cost drivers

- Explore alternative sourcing locations

- Evaluate design changes for cost savings

- Make data-driven decisions to sustain profitability and minimize risk

- Provide leverage for fact-based negotiations

The 2025 tariff challenge underscores the need for advanced tools like aPriori to future-proof supply chains and maintain a competitive edge.

Data Is Your Supply Chain’s New Currency

Discover how AI-powered sourcing insights mitigate supply chain risks, lower costs, and streamline and maximize opportunities