Digital Twin Technology Takes Center Stage and Other MIC ’23 Takeaways

Key Takeaways:

- Watch digital manufacturing case studies for innovators including Carrier, Eaton, TE Connectivity, Signify, and more.

- Get real-world digital transformation examples that address profitability, sustainability, risk, and other manufacturing industry challenges.

The Full Article:

Rising material and energy costs, supply chain instability, and an evolving regulatory environment make it difficult for manufacturing leaders to optimize production costs and sustainability efforts. To address these and other challenges, the 2023 aPriori Manufacturing Insights Conference (MIC) gathered manufacturing executives, industry leaders, and aPriori experts.

This year’s MIC theme, “Digital Twins: Reimagined,” focused on how manufacturers are using digital transformation (DX) solutions to reduce costs, improve sustainability, shorten development times, and meet customer demands for high-quality products. MIC 2023 featured presentations from leading manufacturers, sessions, and networking opportunities to discuss how manufacturers are implementing digital twin technology to achieve short- and long-term goals.

The conference featured speakers from notable manufacturers including The Boeing Company, GE Appliances, Carrier Corporation, Eaton, TE Connectivity, and Signify. These speakers offered diverse experiences and insights, particularly in cost engineering, value engineering, digital design, and procurement.

Read about the key themes and takeaways from MIC 2023:

Rethink Your Supply Chain with Insights from Strategist Peter Zeihan

Peter Zeihan, an expert on geopolitics and the global economy, provided the MIC 2023 keynote address. He shared the challenges manufacturers face in the current era of material shortages and geopolitical instability, offering insights on how companies can capitalize on these economic conditions.

Specifically, Mr. Zeihan (and others) believe that a globalized supply chain will become increasingly regionalized to provide resilience against geopolitical instability, natural disasters, or pandemics such as COVID-19. He notes: “In a disconnected world, any point of exposure is a failure point, and any manufacturing system that cannot snuff out its own complexity is one that will not survive. The model of dozens of geographically isolated suppliers feeding into a single, sprawling supply chain will vanish. Instead successful manufacturing will twist into new, mutually supportive shapes.”

In short, Mr. Zeihan believes that “… everything about our interconnected world – from how we manufacture products, to how we grow food, to how we keep the lights on, to how we shuttle stuff about, to how we pay for it all – is about to change.”

Address Sustainability Across the Product Lifecycle

Sustainability Fireside Chat with aPriori, PTC, and Vestas

How can manufacturers really apply digital transformation capabilities to drive value? How do you advance your digital transformation roadmap to address business challenges, and how do digital twins factor into successful implementations? Watch our fireside chat and get insights into these topics and more with the following:

- Stephanie Feraday, President and CEO, aPriori

- Catherine Kniker, Chief Strategy and Marketing Officer, PTC

- Lasse Lundberg Nowack, Head of Engineering Development, Vestas Wind Systems A/S

Watch this session to learn about manufacturing sustainability trends and best practices.

Carrier: The How and Why of Design for Sustainability

Watch Tristan Abend, Value Engineering Manager for Carrier, discuss how aPriori is integral to reaching net-zero emissions by 2050. Mr. Abend also reviews how aPriori’s design for sustainability (DfS) solution provides real-time data and metrics to achieve cost and carbon savings simultaneously. aPriori’s DfS functionality measures embodied and operational carbon, enabling Carrier to design sustainable innovations from the outset.

Learn how Carrier uses manufacturing digital twin technology to enhance corporate sustainability.

Embodied Carbon: The Hidden Cost of Manufacturing

Sixty percent of manufacturers today have defined environmental goals, but 40% still need to implement plans to reduce their negative climate impact. The majority of emissions lie in the supply chain and in the product itself, which is known as embodied carbon. Learn how you can evaluate this along with the potential hidden cost it brings with aPriori’s Mark Rushton and Rodney Burns.

Watch aPriori’s session on identifying and reducing embodied carbon in your products.

Increase Profitability by Advancing Manufacturing Operations

Roundtable: How to Drive Profitability in Uncertain Times

As economic uncertainty continues to cloud the business landscape, keeping costs under control, and finding ways to drive them down, is a top agenda item for many manufacturers. Watch the video and get fresh perspectives from our roundtable:

- Ramelle Gilliland, Vice President of Procurement and Supply Chain, Lightning eMotors

- Craig Melrose, EVP Digital Transformation Solutions, PTC

- John Pilla, former Engineering Executive, Spirit AeroSystems

- Chris Jeznach, Director of Product Marketing, aPriori (moderator)

Get tips from manufacturing executives to keep costs in line and drive profitability.

Eaton: Digital Engineering – The Key to Zero Lead-Time Product Development

Eaton faced challenges in reducing engineering lead times while maintaining product quality and accelerating time to market (TTM). Dr. Uyiosa Abusomwan, Eaton’s Senior Digital Engineering Manager, outlines how aPriori enables the manufacturing company to reduce product development time by 80%. He also discusses how Eaton implemented a three-step digital engineering strategy to meet its objectives.

Watch Eaton’s presentation on digital engineering and the future of product development.

Optimize Your Supply Chain

TE Connectivity: Supplier Strategies to Manage Cost & Risks

Amid global shifts in supply chain dynamics and relentless inflationary pressures, maintaining competitiveness requires a data-driven, collaborative approach. Sylwia Lambert, Director of COE Procurement Cost Analytics at TE Connectivity, provides a deep dive into actionable, data-backed strategies to foster enterprise-wide productivity.

Watch TE Connectivity’s strategy to improve cost modeling and increase operational efficiency.

Signify: The Power of Creative Procurement

Can successful manufacturing procurement be both an art and a science? This presentation showcases the power of creative procurement and Signify’s journey to digital transformation. Signify’s Arnold Chatelain shares his perspective on the importance of having your facts and understanding the person on the other side of the negotiating table to be successful. Mr. Chatelain also details how Signify uses aP Generate to automate the design for cost/manufacturability analysis process and help to address the business challenges Signify is addressing.

Apply Digital Twin Technology to Advance Your Manufacturing Capabilities

The 2023 Manufacturing Insights Conference presented a comprehensive view of the current challenges and opportunities in the manufacturing industry. Through expert discussions, case studies, and technology showcases, aPriori’s 11th annual event provided valuable insights and practical tools for enhancing efficiency, reducing costs, and promoting sustainable manufacturing practices.

Manufacturers that apply digital twin technology to gain real-time visibility into data across the product development lifecycle will be well-equipped to make informed decisions quickly and confidently.

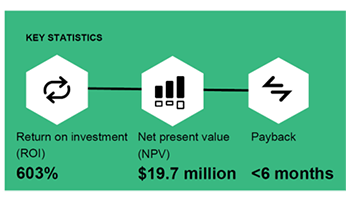

Get a 600% ROI with aPriori

Read Forrester's report to learn how aPriori can cut costs and drive growth.