aPriori Spring ’24 Cloud Release Update

aPriori’s spring 2024 cloud release provides new levels of speed and usability for product manufacturing teams to increase profitability, time to market, and more. This quarter’s updates raise productivity with more ways to analyze data quickly and collaborate seamlessly across teams, such as design and cost engineering, sourcing, sustainability, and project management.

We’ve categorized our new Manufacturing Insights Platform features into four areas:

- aP Design: Scenario History and Reporting Flexibility

- aP Generate: New Focused, Role-Based Alerts to Scale Easily

- aP Workspace: Manage Messages & Tasks Easily Across Multiple Scenarios

II. Data and Modeling Enhancements

- RDLs: Material Price History at Users’ Fingertips

- Machining

- Electronics/PCB Fabrication

- Casting, Forging, and Powder Metal

III. Sustainability Enhancements

- Carbon Estimates for All Standard Machining Operations

- BOM Loader Support

- Elevate Accuracy With CO2e Data

- Contributor-Only Licensing

- Self-Service User Management for aPriori Cloud

- Usability Enhancements

I. Productivity Enhancements

aP Design: Scenario History and Reporting Flexibility

We’ve added even more flexibility to chart scenario changes over time. The History Plots feature shows scenario criteria updates across multiple design iterations – such as fully burdened cost, CO2e, design for manufacturability (DFM) risk, and other KPIs. We provide additional visual clarity for design reviews and other status updates by enabling users to omit select design iterations and focus on overarching trends regarding cost, etc.

Users can download and share the scenario history quickly and control which iterations to include.

aP Design Parts Report

Additionally, our aP Design Parts Report now enables users to download all assembly scenario data in a single spreadsheet. This feature makes it easier and faster to share product data with colleagues.

aP Generate: New Focused, Role-Based Alerts to Scale Easily

aP Generate provides automated insights at scale for product design teams to identify and prioritize potential design issues quickly and efficiently. aP Generate automatically analyzes designs checked into an organization’s product lifecycle management (PLM) system and prioritizes identified issues based on severity and type (e.g., cost, DFM, etc.).

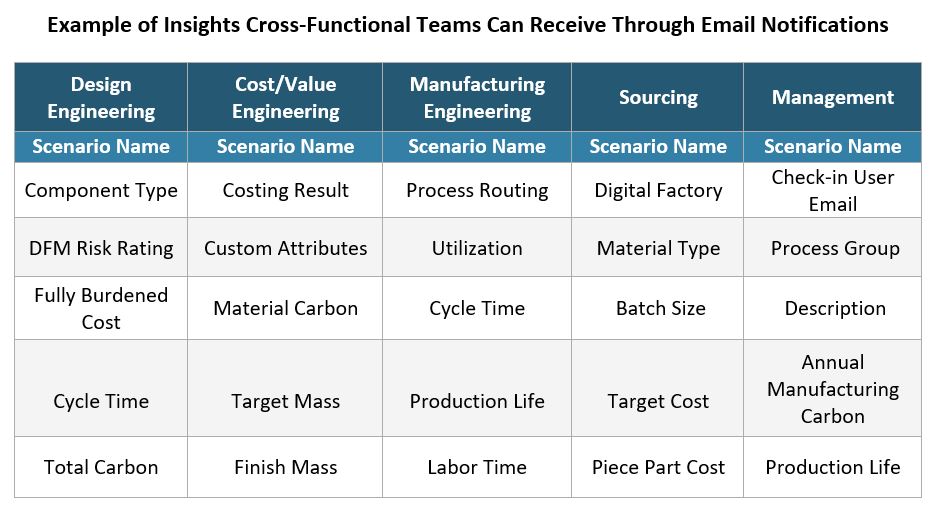

aP Generate’s new Flexible Notifications enable users to customize alerts according to their roles, such as cost engineering and design engineering. For instance, cost engineers can choose only to receive cost-related alerts and other relevant notifications associated with their departmental tasks. Conversely, design engineers can receive actionable alerts to focus and prioritize the designs with the highest manufacturability risk.

Once users review alerts via email, they can collaborate with the rest of the team by accessing or refining the full scenario in aP Workspace or aP Design.

Table Description: Within a Flexible Notification setup, users can select various insights (up to 6 columns) pulled from the PLM system, production inputs, costing outputs, user-defined attributes, and additional or administrative information. Users can also further filter these insights to focus only on the components needing their attention.

aP Workspace: Manage Messages & Tasks Easily Across Multiple Scenarios

Our enhanced aP Workspace Projects feature makes it easier to navigate and sort through multiple scenarios simultaneously to locate assignments. Users can easily access, filter, and engage with scenario-specific communications, thereby enhancing efficiency within costing projects. Additionally, the ability to directly select relevant parts for comment review on the Project Details page accelerates the review and response process, facilitating faster data-driven decisions and saving time.

II. Data and Modeling Enhancements

RDLs: Material Price History at Users’ Fingertips

Now, users can access historical raw material cost data to quickly review material price history, analyze market trends, and refine procurement strategies with precision. Learn more about our latest RDL economic updates and capabilities.

Machining

Access Complex Machining Scenarios Quickly

Users can now open two-model machining scenarios twice as fast. This accelerated process reduces the time required to access scenarios, allowing users to focus more quickly on optimization and decision-making.

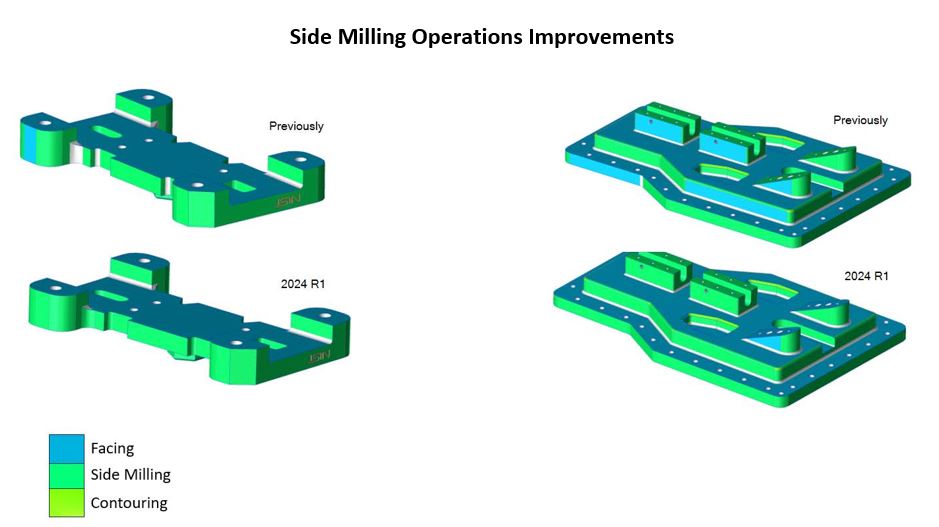

Improved Side Milling Operation Assignment for Neighboring Surfaces

Our side milling operation updates enhance the accuracy of machining models across chains of adjacent surfaces. This refinement treats logically connected surfaces as a continuous chain to improve overall production quality and increase precision to produce complex parts to ensure the products meet high-quality standards.

- Summary of Machining Operations:

- Facing: Removes material from the top surface to create a flat, smooth finish.

- Side Milling: Cuts along the sides to create vertical or angled surfaces.

- Contouring: Follows the outline of a part to create complex curves and shapes.

The image below illustrates the improvements in side-milling operations, demonstrating more consistent and precise machining applied across all adjacent surfaces in the latest release.

Eccentric Turning Axes Assignments

Automating the assignment of eccentric turning axes streamlines the costing and manufacturing of parts with off-center features (e.g., eccentric or off-center turning, such as camshafts or crankshafts). This added automation reduces the manual input required while increasing accuracy.

Electronics/PCB Fabrication

Added Dip Tank Processes Precision

Our new mechanistic modeling of PCB dip tank processes provides more precise cycle time and cost estimations. The latest models more accurately reflect real-world operations by considering the sequential and simultaneous processing capabilities of dip tank equipment. By providing a faster estimation of piece-part costs and manufacturing cycle times, PCB manufacturers can gain critical insights to improve efficiency and uncover cost-saving opportunities.

New Laser Drilling Process Support for Microvias

Addressing the challenges of working with high-density interconnect (HDI) boards and microvias, the new release includes a new laser drilling process for vias that are too small to be created with mechanical drills. This new process enhances the precision of costing models and supports the growing market demand for PCB design with finer, more complex board architectures. The announcement spotlights our expanding range of PCB support.

Updated Estimates of Mechanical Drilling Expendable Tooling

The updated estimates for expendable tooling used in mechanical drilling reflect a significant improvement in PCB fabrication cost modeling precision. By adjusting material pricing and the usage of protective plates tailored to actual panel sizes, aPriori provides more realistic cost estimates to manage production expenses better and improve profitability.

Improved Interpretation of Specific ECAD Gerber File Formats

The improved interpretation of specific ECAD Gerber file formats enables aPriori to accurately process and cost PCB designs based on popular ECAD tools like Altium, CADSTAR, and PADs. With this update, aPriori ensures that physical and electrical PCB properties are accurately represented in cost models. This results in more precise cost estimations and facilitates smoother transitions from design to production.

Casting, Forging, and Powder Metal

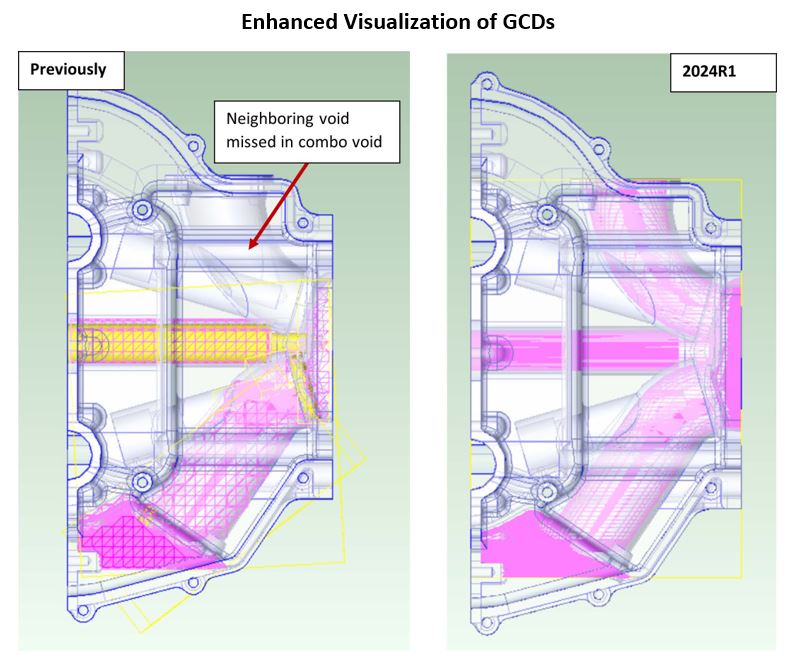

Enhanced Visualization and Estimation of Geometric Cost Drivers (GCDs) Across Casting, Forging, and Powder Metal Processes

aPriori has significantly improved the visualization and estimation of Void and ComboVoid Geometric Cost Drivers (GCDs) across casting, forging, and powder metal processes. These enhancements are now clearly represented in the 3D Viewer, providing a more detailed and accurate depiction of voids. Voids are critical empty spaces or gaps within molds or parts that significantly influence manufacturing considerations and costs.

The image below demonstrates the enhanced visualization of GCDs in the new release, offering a more detailed and accurate depiction of voids compared to previous versions.

Casting process enhancements provide a clearer and more detailed representation of Void and ComboVoid GCDs in the 3D Viewer. This boosts the accuracy of tooling approach determinations, enabling foundries and manufacturers to optimize their operations with greater precision. Such detailed visualization ensures robust and precise data for decisions regarding mold design, material selection, and production planning, ultimately reducing unforeseen production issues and enhancing output quality.

Similarly, updates for forging and powder metallurgy standardize the extraction and visualization of these GCDs, leading to more accurate void detection and consistent tooling cost predictions. These improvements increase the credibility of the extracted GCDs, thereby enhancing the subsequent tooling and costing decisions. The standardized approach in powder metal manufacturing ensures better budgeting and operational planning, mirroring the benefits seen in casting.

III. Sustainability Enhancements

The latest update to aPriori Sustainability Insights includes the integration of ecoinvent’s latest LCI database (v3.10), BOM Loading for CO2e and cost data from purchased commercial off-the-shelf (COTS) parts, and enhanced emissions measurement and reduction capabilities. Learn more about our carbon reduction and sustainability excellence capabilities.

Carbon Estimates for All Standard Machining Operations

We are thrilled to announce that all standard machining operations now include comprehensive carbon emissions estimates. The enhancement calculates the carbon emitted from the energy consumed by the machine’s spindle during material cutting, making this information accessible through the system’s detailed reporting tools. This allows manufacturers to identify the most carbon-intensive operations, modify procedures, select alternative materials, or change equipment settings to reduce overall carbon emissions.

BOM Loader Support

The enhanced bill of materials (BOM) Loader module now seamlessly imports and integrates complex BOM data into aPriori, with a new focus on sustainability. This update allows for the direct inclusion of carbon emissions data, covering areas such as material carbon, electricity process carbon, consumable process carbon, and logistics carbon.

Moreover, the updated BOM Loader helps manufacturers calculate the total carbon of an assembly composed of multiple bought-in or commercial off-the-shelf (COTS) components. Users can also add various components or assemblies to an aPriori roll-up, enabling them to quickly assess and minimize the cost and carbon impacts of critical bought-in parts.

Elevate Accuracy With CO2e Data

aPriori now alerts users when material property data required for accurate carbon emissions calculations is missing. This new feature ensures that users are aware of data gaps that could compromise the integrity of sustainability assessments. It aids manufacturers in complying with various environmental regulations by providing comprehensive data for precise carbon accounting.

Refine Energy Consumption Calculations with Custom Data

The enhancement enables energy consumption estimates in customers’ digital factories using custom overhead rates instead of aPriori’s standard rates. This allows for the calculation of both direct and indirect energy consumption, regardless of the overhead methodology used, contributing to more accurate total carbon emissions data. This update is crucial for manufacturers using custom settings, providing a reliable and transparent approach for identifying energy reduction strategies and enhancing sustainability performance across operations.

IV. Platform Enhancements

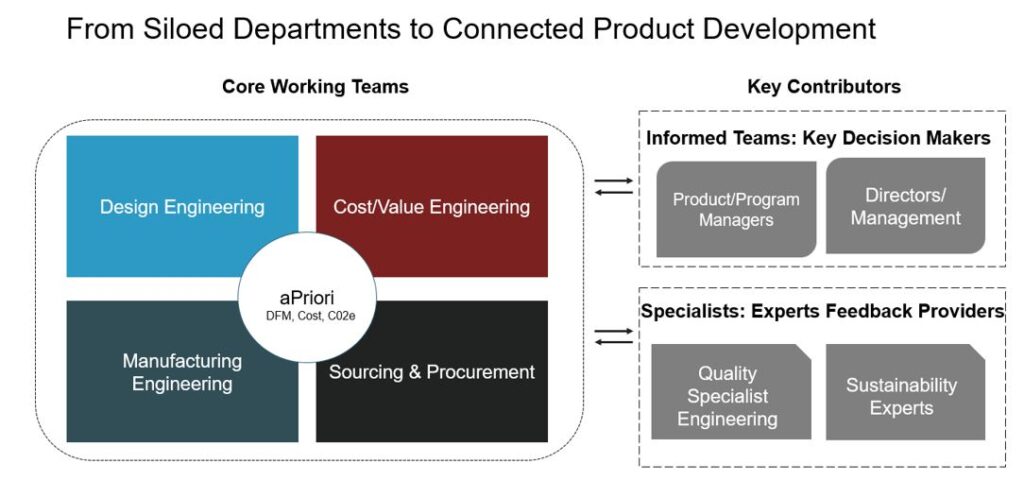

Contributor-Only Licensing

Our new contributor-only license holder can access aP Workspace, allowing more stakeholders within a company to collaborate and view the manufacturing insights generated by aPriori. This license type is designed for stakeholders who need to be informed and make quick decisions or for specialty experts who can provide feedback to be captured within aP Workspace (see the image below).

Self-Service User Management for aPriori Cloud

aPriori Cloud now enables aPriori user administrators to add, update, and delete users easily. By leveraging role-based access control (RBAC), aPriori user administrators can assign roles to users. aPriori Cloud will then grant those users the necessary permissions and assign them a user license.

To make user administration even more convenient, self-service user management for aPriori Cloud is available in two forms: through a new user interface in aPriori Cloud Home or a SAML integration with major Identity Providers (IdPs). We detail both options below:

- All aPriori user administrators have access to a new user-friendly interface, giving them an easy management experience through aPriori Cloud Home.

- For SAML-managed customers, customer administrators can assign aPriori roles via their Identity Provider (e.g., Azure AD or Okta). After successful authentication, the IdP sends the user metadata to aPriori Cloud, enabling automatic user updates based on the provided metadata.

Usability Enhancements

Recover Unsaved Scenarios After AppStream Inactivity Timeout

With the latest update, aPriori prevents data loss due to inactivity timeouts on AWS AppStream, enabling users to recover unsaved scenarios upon returning to their session. This enhancement addresses productivity and continuity by guarding against potential loss of updates or activities.

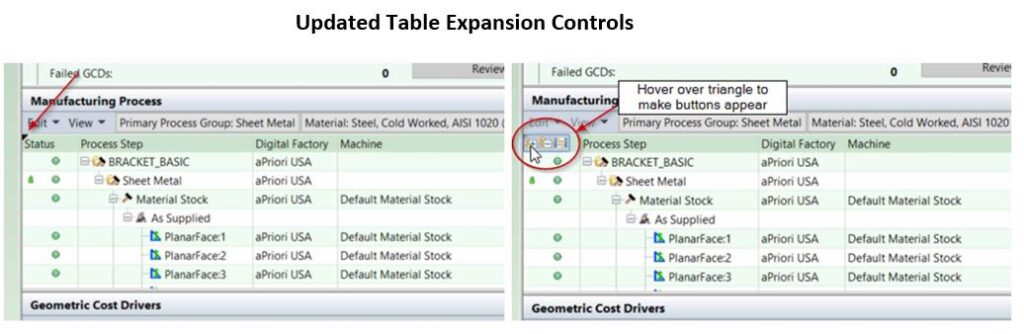

UI Affordance to Make Users Aware of Table Expansion Controls

It’s now easier to identify where data tables can be expanded, making it easy for users to find and use the information they need quickly. A black triangle icon now signals where rows or columns can be extended to show more fields.

When hovering over the black triangle in the left image, expansion buttons will appear, allowing users to view additional detailed information displayed in the right image.

Customer-Focused Enhancements for Our Cloud Manufacturing Software Release

We introduce more than 50 new software releases each year to provide customers with new capabilities to address increasingly complex product manufacturing challenges. Customer insights provide the framework for our cloud manufacturing software release roadmap. We receive suggestions and feedback in various ways, such as strategy meetings with senior manufacturing executives, ongoing professional services/consulting engagements, and from our user groups.

Our updates are designed to help manufacturers increase profitability, accelerate time to market, boost sustainable manufacturing, and reduce risk.

In addition to the new capabilities detailed here, please visit our What’s New Blog section for information about other recent aPriori cloud manufacturing software release enhancements.

Discover how Eaton reduces design time by 87% with AI and aPriori