3 Opportunities to Enhance Manufacturing Agility and Reduce Risk

Key Takeaways:

- Supply chains, inflation, and geopolitical conflicts continue to plague manufacturers

- Manufacturing insights can help overcome challenges, mitigate risk, and lead to greater manufacturing agility

The Full Article:

Although many manufacturers have retooled their processes to meet the challenges of the last few years, issues persist, and new ones continue to crop up. Supply chains maintain a level of unpredictability, often influenced by geopolitical conflicts and ongoing inflation. The PwC 25th Annual Global CEO Survey noted that 43% of CEOs in manufacturing, believe their organizations will not be economically viable in a decade if they continue down their current paths. And KPMG reports that more than six out of 10 international organizations anticipate that geopolitical instability could have a detrimental impact on their supply chains within the next three years.

The good news is that many of these risks can be mitigated with the right manufacturing insights platform. Even better, manufacturers can optimize such platforms to increase agility, greater competitiveness, and staying power.

Mitigate Risk, Improve Manufacturing Agility and Competitiveness

Let’s examine three opportunities to address risk and increase manufacturing agility: the supply chain, inflation, and geopolitical conflicts.

1) Address Supply Chain Risk

The KPMG report found that 71% of global companies recognized raw material costs as their main supply chain threat in 2023. Sixty-seven percent said meeting customers’ speed of delivery expectations played a critical role in their supply chains over the next 12-18 months. Difficulty or delays in obtaining supplies also hamper speed to market. Moreover, traditional quoting methods can impede manufacturing agility and time to market, with conventional quoting times in the eight to 10-week range.

The Opportunity: Despite these issues, many organizations recognize digital technology’s critical role in mitigating supply chain delays, data gaps, and inflated raw material costs. A manufacturing insights platform like aPriori can minimize disruptions and optimize opportunities.

For instance, it can run what-if scenarios, simulate supply and design options, streamline workflows and processes, remove supply chain bottlenecks, break down siloes, and reduce production cycle times in an efficient, cost-effective manner. Additionally, it can provide end-to-end supply chain analytics to enhance visibility, improve supply chain sourcing, quoting, and delivery, facilitate better supplier negotiations, and reduce the costs associated with materials and supply chain management.

2) Counterbalance Inflationary Pressures

The PwC survey also indicated that 40%, 31%, and 25% of those surveyed cited inflation, macroeconomic volatility, and geopolitical conflicts, respectively, as key threats in the next 12 months. It also revealed that 52% of CEOs would reduce operating costs to safeguard against potential economic challenges and volatility in the next 12 months.

The Opportunity: A manufacturing insights platform can identify cost outliers and provide feedback to eliminate them and further reduce costs. It can highlight potential cost reductions at each stage of product development. For instance, design engineers and cost engineers can work together, using Design to Cost to lower sheet metal costs. It also lessens late-stage design changes and post-launch product issues. Sourcing can get ahead of inflation and future supply pricing, applying should cost analysis to anticipate what products could cost to make. Product and price performance can then be optimized, reducing costs by as much as 40% per unit.

As increased pressure to get to market quickly and material delays continue, such tools enable faster methods to reduce production delays and supply chain costs. As aPriori CEO and President Stephanie Feraday noted, digital transformation is propelling some new manufacturing products to market 20-40% faster by connecting operations, sharing data, and accelerating key phases of the product development lifecycle.

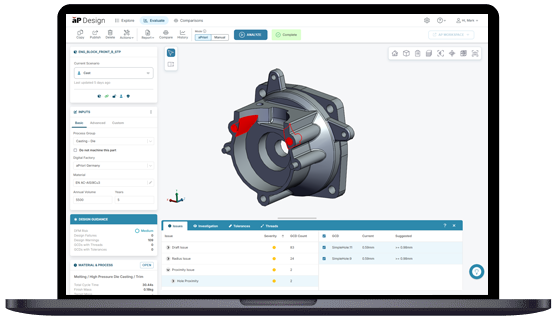

Image 1: aPriori manufacturing simulation in action

3) Provide Resiliency to Navigate Geopolitical Conflicts

Among supply chain and inflation issues, geopolitical conflicts (i.e., war, strained international relations, etc.) are reshaping how and where manufacturers conduct business. In the PwC survey, 32% of executives cited geopolitical conflict as a top threat to growth, and 71% said it could inhibit their ability to sell products or services.

Such disruptions can upend operations, resulting in higher material costs, more complex logistics, and less supply chain efficiency. Economic sanctions, tariffs, and natural disasters also can disrupt critical supply channels, adding to delays and driving up costs.

The KPMG report revealed that more than seven out of 10 companies announced a shift of their manufacturing locations between 2018-2023, moving operations into Asia. However, as we’ve witnessed over the last few years, Asia is vulnerable to geopolitical disruptions as well.

The Opportunity: With platforms like aPriori, manufacturers can determine the feasibility and costs of a design in the early stages. If they are typically reliant on supplies or production in a tenuous region, they can work through the design to determine other geographic regions for supplies, how they can cut costs if required material prices skyrocket, and whether it makes more sense to offshore or onshore production based on geopolitical conflicts currently impacting them. They can get real-time visibility into their supply chains and logistics. Sourcing can rely on the Regional Data Libraries (RDLs), now in nearly 90 geographic locations, to compare price variances between regions. It is particularly useful to find alternatives to supplier areas impacted by geopolitical conflicts.

Leverage Manufacturing Insights and Cloud Technologies for Long Term Growth

The PwC survey concluded with 69% of CEOs indicating, that within the next 12 months, they will deploy technologies like cloud. These technologies foster greater collaboration, improved end-to-end visibility through the product development lifecycle, and the ability to enhance manufacturability, cost, and sustainability without compromising value, time to market, or profitability.

A McKinsey article noted that, when implemented successfully, many sectors experience 30-50% decreases in machine downtime, 10-30% throughput increases, 85% more accurate forecasting, and labor productivity improvements of 15-30%. Those manufacturers will be well-positioned to tackle the challenges that come their way. Better still, they will build resilience and manufacturing agility that will ensure long-term growth.

What Can Cloud Collaboration Do for You?

Discover how aPriori optimizes it with our manufacturing insights platform