August 26, 2024

How Much Profit Is Wasted By Design Delays?

Transcript

Time is money, we’ve all heard told, but for manufacturers designing and releasing new products to the market, how much money is it really worth to be on time? Or put another way, what is the real cost of delays when it comes to design engineering?

Matt Mullan is the Senior Director of Cost Model Development at aPriori, and the author of the article: Optimize Time Spent in Design to Boost New Product Introduction. Matt Mullan comes from decades of experience in aerospace engineering and cost modeling, and he’s brought to us today some sobering statistics on the cash value of time, as well as some concrete solutions on how to recoup both time and savings in the design process. Matt Mullan, welcome to the podcast.

Matt Mullan: Thanks, Leah.

If you delay a product launch by 6 months, you lose a third of your profits

Leah Archibald: So, you say that on average, companies lose about 33% of after-tax profit when they ship a product, even just six months delayed. Why is that number so big and where does it come from?

Matt Mullan: The statistic itself actually came from a study by McKinsey & Company, and it has been further validated more recently. But ultimately, the longer a product is in development cycle, revenue is not being earned. Everything is a cost before that point. If you’re late to market, then you miss that first mover advantage, you miss the opportunity to capitalize on being the first product on the shelf, the first vehicle in a line, etcetera. And if the product lifecycle is short, that effect is going to be amplified.

Overspend your development budget by 50%, and you still won’t lose as much money as a delay

The flip side to that statistic in the McKinsey survey was that an overspend on product development budget of up to 50% actually only resulted in a 3.5% decrease in peak profit over the life of the product. And it doesn’t matter whether it’s aerospace or automotive or consumer goods, being there first has a massive advantage.

Leah Archibald: Can you give us a real example of the cascade of costs that happens when a design is delayed?

Matt Mullan: Definitely. There is multiple different guises in which this cost manifests itself. If a design is late to sourcing, then the RFP (Request for Pricing) or the RFQ (Request for Quote) phase may be reduced and the sourcing agents have less time to negotiate the best price on a particular design. If we look at a part that’s being manufactured in-house, the manufacturing engineer has to make decisions in a shorter space of time in which to get the most optimum manufacturing rate. And if there is tooling consideration, the delay to the release of the tooling design could lead to an expedite cost in order to get that tool in-house in time to start making the product.

But probably the most direct impact is penalty fees. If a manufacturer is a Tier 1 to an OEM producer, their first delivery is not only holding up their schedule, but it’s holding up the schedule of an aircraft. Those penalties for late delivery of a critical component of an aircraft are massive. We’ve seen examples where Tier 1s have actually had to absorb the cost for shipping in order to get product to the OEM on time. So if you’re behind in your manufacture and you don’t have enough time to take a sea route, then you have to have a transporter to fly the product. And each of those flights could cost a million dollars.

What mistakes in design lead to time-to-market delays?

Leah Archibald: So why are these delays happening? What is it that the design engineers should know that they don’t know with their design process?

Matt Mullan: Being a design engineer is a tough job. They are working in an envelope of increasingly constraining factors. Ultimately, the aim of a design engineer is to develop a well-integrated and highly functional product and at the same time try to ensure that the product is manufacturable and that it meets a cost target. If we look at the design manufacturing space, those constraints are becoming ever more complex. They’re having to account for additional safety requirements and additional manufacturability constraints. But these are all competing priorities. Increasing the safety of a part will have a consequence on how it’s manufactured, what materials are chosen, and what it’s going to cost ultimately. So they are competing priorities.

Leah Archibald: What I’m hearing is that a design engineer looking to solve a problem can only focus on so many considerations at the same time. And if they change the material, well, that changes the cost and the carbon footprint.

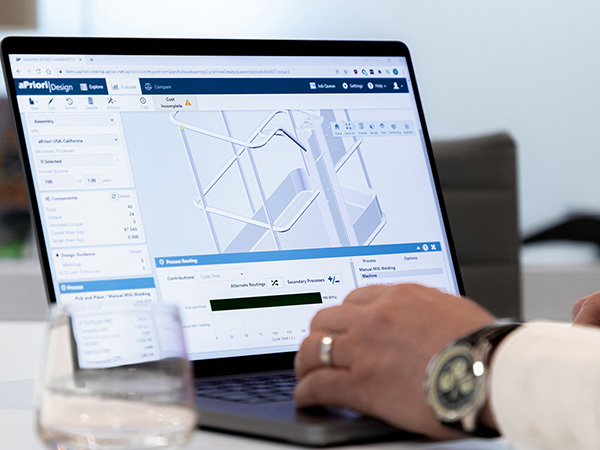

Matt Mullan: Exactly. Having insight into what the impact of those decisions will be is super valuable. Having an automated manufacturing insights engine provide guidance – provide immediate feedback into cost implications, manufacturable implications also sustainability implications – is essential. Optimize the time that the design engineer is spending working on a design. Because ultimately there will be multiple design engineers working on multiple parts that all have to come together. And the amount of oversight that it requires to check all the specific features on any particular design is time consuming.

Leah Archibald: Time consuming and manual for a person to do, but quick and easy for a software engineer.

Matt Mullan: Exactly. That automated feedback doesn’t require the iteration to go from one person to the next. It is all done at a single station. And it is considering multiple different aspects of the constraints that a designer has to work within. So if it’s a cost implication, if it’s a manufacturable implication or if it’s a sustainability implication, those are all done in the same iteration cycle.

A single designer can’t prevent costly time-to-market delays, but aPriori can

Leah Archibald: So when I ask the question, “how can teams prevent these delays from happening?” what I hear is that automated insights through a solution like aPriori let the design engineer see: “Hey, this might be a problem in the future. Maybe talk to manufacturing about the manufacturability or take a look at cost alternatives.”

To get all of that right in the software that they’re using to do their designs, those insights will prevent late stage changes which delay time to market and lower profits.

Matt Mullan: Implementing those manufacturing insights early in the product development lifecycle mitigates the late stage changes that will inevitably cost not only time but also money. Having the designers get that immediate feedback rather than having to wait for the part to move through the production lifecycle is invaluable for the organization in order to hit those time-to-market targets that have been set well in advance of any design starting.

Leah Archibald: So when design engineering gets it right, then the sourcing team can go out and negotiate with more time to get a good price. And the customer is getting the final product when they expect it. All those elements roll into the final profit.

Matt Mullan: Exactly. If we hit the target in the design phase, then it allows the remainder of the phases to hit their targets as well.

Leah Archibald: May we all see more profitable products on time! Matt Mullan, thank you so much for joining me on the podcast today.

Matt Mullan: Thanks, Leah.