Quantified DFM Improves Product Development

Key Takeaways:

- Without quantified DFM during design, engineering is accountable for cost but lacks real control over it

- The real constraint is late visibility. Speed, quality, and margin only conflict when manufacturability is discovered too late. Early insights replace rework with velocity

- Measure manufacturability to protect margin. When manufacturability is quantified during design, cost reduction becomes proactive, launches become predictable, and margin becomes engineered

The Full Article

Engineering Is Responsible for Product Cost — But Rarely Accountable

In nearly every manufacturing organization, engineering is responsible for product cost — whether formally acknowledged or not. Decisions on the geometry of a part, the selected material, the tolerances applied, the number of fasteners specified, and the complexity of an assembly determine the economic fate of a product long before it reaches a customer.

And yet, in most companies, engineering is not truly in control of cost. That disconnect is not philosophical. It is structural.

Design engineers are trained to optimize fit, form, and function. They are measured on performance, durability, safety, compliance, and speed to launch. Cost, by contrast, often enters the conversation later — after sourcing feedback, tooling quotes, and validation builds. By then, the majority of the cost structure has already been designed in.

Engineering teams influence cost more than any other function. But without quantified manufacturability, it cannot fully control it.

The Illusion of the Speed–Cost–Quality Tradeoff

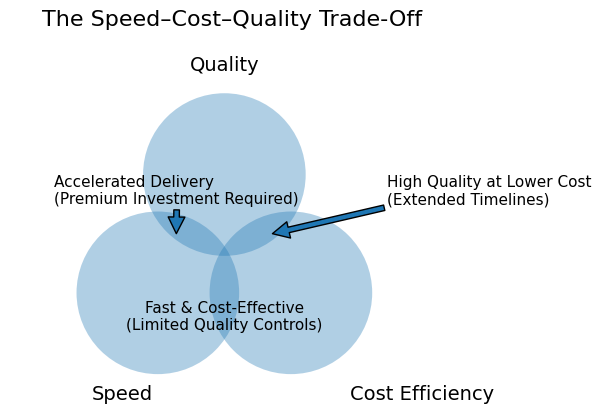

We are all familiar with the classic Venn diagram: speed, cost, and quality locked in tension, as if optimizing one inevitably compromises the others. It has shaped decades of management thinking and reinforced the belief that tradeoffs are unavoidable.

Figure 1: Where Speed, Quality, and Cost Intersect In Product Development

What if this tradeoff persists not because of physics or economics, but because it is checked late in the process and manufacturability is unmeasured?

Engineering organizations are judged on speed to launch, product performance, predictability, and margin integrity. When launches slip or margins compress, leaders often attribute it to complexity, supply chain volatility, or aggressive timelines. Yet beneath those explanations lies a quieter constraint: manufacturability evaluated through experience rather than quantification.

When speed and precision appear to conflict, it is often because the direction is unclear. Speed without visibility leads to rework. Precision without manufacturability leads to late discovery. The tradeoff is not inevitable — it is informational.

When Manufacturability Is Subjective

Engineering is a discipline grounded in measurable tolerances and simulations. Structural performance is calculated. Thermal behavior is modeled. Fatigue life is predicted. Yet the ability to manufacture what is designed — at scale, at cost, and at margin — is frequently assessed through opinion and previous experience.

Manual DFM reviews depend on who is in the room. Supplier feedback arrives after critical decisions have been made. Risk is categorized as “high” or “low,” with no quantified severity. Assembly challenges surface during pilot builds rather than during concept refinement.

The downstream effects are familiar: ECOs multiply, tooling changes occur late, assembly complexity grows unintentionally, and margins erode quietly. Cost-cutting programs emerge not as strategic initiatives but as corrective actions.

In this environment, speed becomes fragile. Launch timelines depend less on engineering excellence and more on how many late surprises surface.

Cost Is the Quantitative Expression of Manufacturability

Cost is often treated as a financial metric — a number calculated in ERP systems or negotiated during sourcing events. But cost is, in reality, a measurable output of design decisions. It is the quantitative expression of manufacturability.

If a design requires secondary operations, excessive cycle time, specialized tooling, or inefficient assembly sequencing, those realities translate directly into cost. If material selection drives scrap rates or regional process constraints, the financial outcome reflects it. Cost is not imposed on engineering; it is produced by engineering.

The problem goes back to accountability. Engineering owns fit, form, and function, but financial feasibility is often left to Sourcing. However, the issue is timing. When manufacturability is measured late, cost becomes reactive. When manufacturability is quantified early, cost becomes engineered.

That distinction changes the nature of accountability.

The 70–80% Lock-In Effect

It is widely acknowledged that 70–80% of a product’s cost is determined during early design phases. Concept architecture, material assumptions, and process selection set the economic trajectory long before sourcing begins.

Yet paradoxically, this is when visibility into real manufacturing impact is lowest.

Designs are optimized for performance and compliance. Tradeoffs such as material reduction or tolerance tightening are debated without full clarity on downstream routing implications. Regional manufacturing differences remain abstract. Procurement is left to negotiate within the constraints that engineering has already embedded.

Consider that a component may be materially less expensive in one region than in another due to differences in process capability and routing efficiency. Without quantified insight into those realities during design, engineering cannot intentionally design toward them. Opportunities are lost not because teams lack talent (though this can be the case with inexperienced team members), but because they lack immediate feedback.

When visibility is delayed, leverage is lost.

From Speed to Velocity

Organizations often pursue speed as a primary competitive advantage. But speed alone does not guarantee success. What engineering leaders truly require is velocity — efficient movement in a deliberate direction.

Velocity requires early course correction, not after tooling investment. It requires clarity before pilot builds. It requires measurable manufacturability embedded within the design workflow.

What slows launches is rarely the presence of analysis. It is the absence of early insight. Late ECOs, tooling redesigns, supplier pushbacks, and emergency cost-reduction initiatives consume more time and resources than proactive manufacturability evaluation ever could.

The concern that new tools may slow the development process is understandable. Yet downstream rework slows organizations far more than early clarity.

Engineering as the Guardian of Margin Integrity

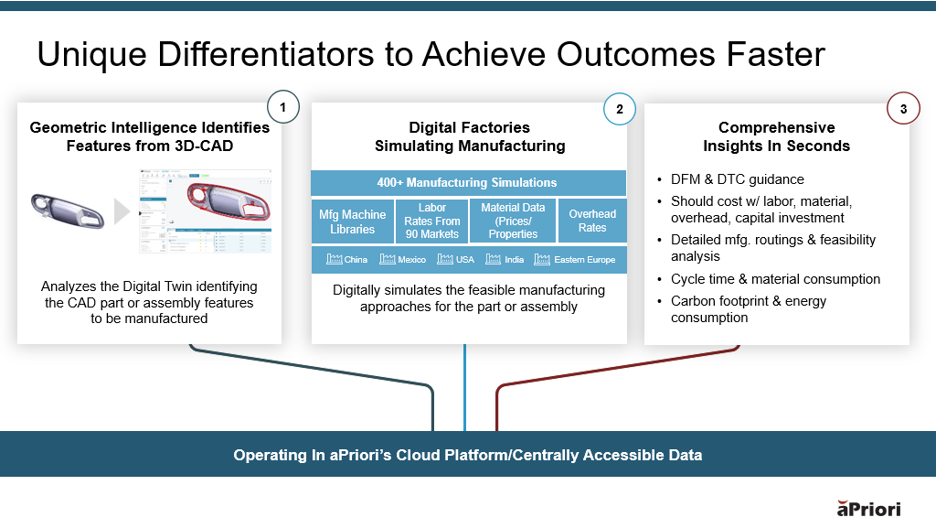

When manufacturability is quantified directly from CAD — with real-time insight into cycle time, process feasibility, regional routing, and should-cost breakdowns — engineering gains strategic control.

Design reviews shift from opinion-based debate to data-driven decision-making. Severity scoring replaces subjective risk labels. Scenario comparison allows teams to evaluate cost, manufacturability, and sustainability side by side. Embodied carbon and energy modeling become part of the same engineering conversation as wall thickness and draft angles.

Junior engineers gain encoded manufacturing intelligence. Senior engineers focus on innovation rather than cost recovery. The entire team gets consistent, data-driven guidance. Cost reduction is embedded in design rather than negotiated after the design freeze. Margin integrity transitions from aspiration to engineered outcome.

Figure 3: With quantified DFM, manufacturability issues can be identified early in design, ensuring streamlined product development and cost control without sacrificing quality.

The Strategic Implication for Engineering Leadership

For VPs of Engineering, the stakes are structural. Without quantified manufacturability, NPI volatility increases, margins compress unpredictably, and cost reduction becomes cyclical. Over time, organizations normalize reactive correction as part of their operating rhythm.

When manufacturability is measurable early, first-pass success improves. Launch predictability strengthens. Cost drivers are eliminated before tooling. Sustainability decisions can be evaluated alongside financial impact rather than treated as tradeoffs.

The difference is not incremental efficiency. It is control. Engineering moves from influencing cost to intentionally shaping it.

Precision Requires Measurement

Engineering is built on precision. Precision demands measurement. Manufacturability must be treated with the same rigor as structural integrity or thermal performance.

Cost is not separate from engineering. It is an additional measurable outcome of engineering decisions.

When manufacturability is unmeasured, speed becomes fragile, and margins become vulnerable. When it is quantified early, velocity increases, risk declines, and cost-cutting programs give way to engineered optimization.

Engineering has always been responsible for product cost. The opportunity now is to take ownership of it.

Is Your Design Precision At Odds With Time To Market and Cost?

It’s not an uncommon problem. You might get the design just right, but it could be cost-prohibitive, resulting in delays. Or you could focus on getting to market quickly, but at what cost and quality? This webinar helps quantify your design so it is not an either/or proposition.