Does AI Really Help Find the Design Needle In A Haystack? Not Without Automated DFM Analysis

Key Takeaways:

- Designing for Manufacturability (DFM) is increasingly challenging for engineering teams due to experienced engineers retiring and pressure to shorten product development timelines

- Where and when to use AI technology and automated geometry-simulation in the product development cycle to accelerate product development

- Artificial intelligence (AI) is not the “be-all, end-all” in product development data analysis

- AI can be leveraged in conjunction with automated DFM analysis to further distill data to ensure product development optimization

The Full Article:

Artificial Intelligence (AI) is everywhere. AI is the latest buzzword. Many believe it’s a “be-all end-all” solution in addressing product development data analysis.

In the current manufacturing landscape, “AI” has become the default answer to every efficiency problem. But for Design for Manufacturability (DFM), jumping straight to AI often puts the cart before the horse.

While the industry promises that AI will solve everything, many engineering teams are finding that these black-box investments lack the precision, transparency, and immediate ROI needed in design engineering today. To build genuine trust in the DFM data, engineering pragmatism must be applied, and manufacturers must recognize that AI is not a solution unto itself.

Although AI is adept at reviewing massive datasets to find patterns, it lacks firm accuracy and transparency. For example, some solutions train AI models on historical ERP data to predict future production costs. The flaw? If you’ve been overcharged by suppliers for years, the AI will simply learn to keep overcharging you. Bad data in, bad decisions out. Other solutions learn from engineers’ DFM feedback comments. But these comments need validation, may be inconsistent, and will take a long time to catch all potential issues and offer value.

Manufacturing feedback is traditionally qualitative—opinion-based “tribal knowledge” that requires endless iterations and experience with manufacturing (which takes many years to build for recent graduates). Relying solely on AI won’t fix this broken process. You don’t need “artificial” intelligence; you need Intelligent Automation.

Instead of “AI-washing” everything in a quest for a quick solution, we need to take a more pragmatic approach.

AI Has Its Merits, But Is Not The Default Solution

Although AI can gather, analyze, and synthesize vast amounts of data to find patterns and make predictions, it also has its pitfalls. For one, there is little transparency in the data. What is the source(s)? Is there full impartiality in the information that is provided? Equally important, how factual or accurate is the data? Is there a way to substantiate it?

While the industry promises that AI will eventually automate everything, many engineering teams are finding that these high-cost investments lack the precision and immediate ROI needed in design engineering today.

One notable shortcoming is that it is not focused solely on the technology itself, but rather on the fact that high-quality, labelled, 3D data ready for training an AI solution is in short supply. Inversely, there is an abundance of 2D data and relative ease of consumption in several standardized formats.

Since engineering design is heavily 3D-native today, this is a problem. There are many formats, and small data errors can have a dramatic effect on AI solutions. As a result, leveraging AI to accelerate DFM checks leads to a delay. This delay can be attributed to the training, verification, and validation that are required.

DFM “rules” are widely accepted (if not necessarily widely known) for many manufacturing processes. Consequently, it becomes a case of checking 3D data against those guidelines. In this case, to accelerate the process, automation is a much better technology today, for this application than AI, since it removes many of these bottlenecks.

A lack of automation from a design perspective leads to inefficiencies in product development, including lengthy design process reviews, slow manufacturing feedback, and insufficient data to drive informed decision-making. What’s more, newer design engineers may lack manufacturing knowledge or not have readily available access to tribal knowledge.

Design feedback for a specific manufacturing process is typically qualitative, requiring more iterations to determine what “looks right,” and is often opinion-based rather than quantitative, which is more consistent and data-driven. Feedback from a design review meeting may be along the lines of “this area needs more draft”, or “that hole is too close to the edge”, or even that “the undercut there will make the tooling more expensive”. Even if values are given for dimensional changes, they are rarely quantified in terms of impact on cost or cycle time, so is it even worth the redesign efforts? This is why Quantified DFM is a game-changer.

Relying solely on AI won’t fix a broken process. It is as important as ever not to focus on technology, but on the challenges instead. Automation should not be overlooked where large amounts of data and speed are concerned. Manufacturing executives focus on the AI buzz because they want to ensure their organizations “don’t get left behind”. However, even if a design engineer uses AI to obtain DFM feedback, it is still unlikely to be quantitative feedback.

For example, they may train an AI model on their ERP systems to calculate the cost of specific parts based on historical costs. But what if those costs have been too high? That data now becomes null. Simply put, AI cannot fix everything, is not 100% accurate, and is only as effective as its training.

“We identified nearly $9 million in cost savings opportunities by using aPriori to evaluate designs earlier and make more informed cost decisions.”— CNH Industrial, aPriori Case Study

Automated DFM Solutions=Mechanistic, Transparent Consistency

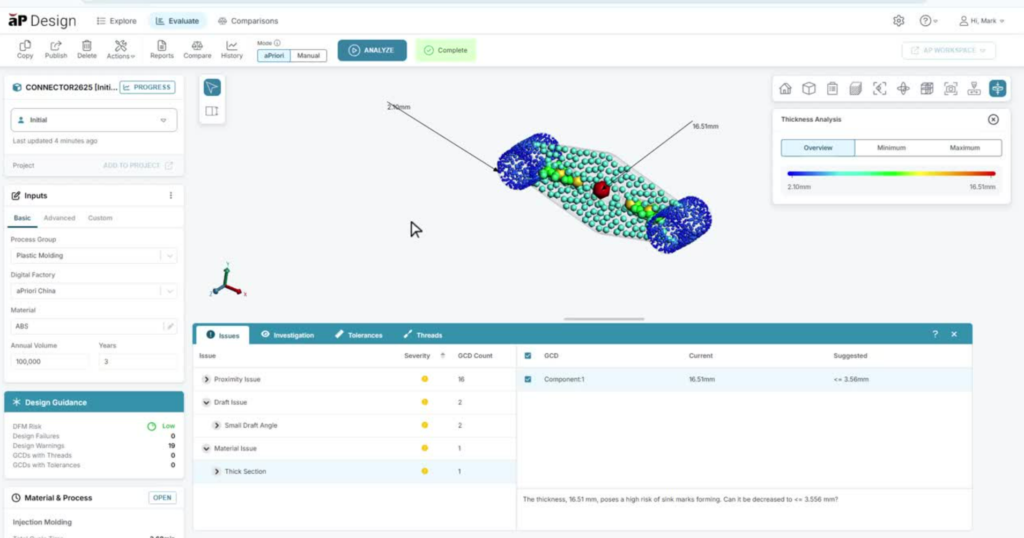

A deterministic, mechanistic model—like the one powering aPriori—provides a defendable, negotiable, and quantitative foundation that AI simply cannot match on its own.

- Quantitative vs. Qualitative: Move away from “what looks right” to data-based analysis that gives design engineers a universal figure for comparison.

- The “Needle in the Haystack”: Our automation pinpoints critical DFM errors in real-time across thousands of components without the unpredictability of early-stage AI.

- Design Momentum: By running fully automated DFM/DFX analyses upon PLM check-in (via aP Generate), you remove bottlenecks caused by waiting for supplier quotes or feedback and enable high-velocity product development.

Engineering-Led EBITDA Impact

Choosing the right tech stack isn’t about following trends; it’s about business outcomes. Companies like CNH have leveraged this structured approach to achieve:

- Faster Time-to-Market: Focus on priorities rather than waiting for feedback loops.

- Increased Profitability: Win more profitable business with accurate, consistent cost data.

- Future-Proofing: True value is created when AI is layered onto a foundation of proven logic—not used as a substitute for it.

Automated DFM solutions, such as aPriori, run mechanistic analyses. Of course, manufacturers can still leverage AI alongside an automated DFM tool to obtain more refined analytics.

However, the mechanistic and transparent consistency of the automated DFM solution will always supersede that of AI.

DFM rules and best practices have been established for many years. The intelligence is already baked into automated DFM solutions like aPriori. In the case of aPriori, it can also be configured to match a manufacturer’s capabilities. As a result, the data users receive isn’t just pulled from random sources. It is primarily inherent to (and driven by) the user’s own product and manufacturing context.

Finding the Needle in the Haystack with aPriori Automated DFM Analysis

Many design engineers must search for the needle in the haystack when analyzing manufacturability. They may find DFM problems on a part or discover manufacturability issues, such as tolerances that are too thin or wall thickness that is not sustainable, within a haystack of components during the design phase.

aPriori can find the needle in the haystack, filtering out noise and pinpointing critical errors without the unpredictability of early-stage AI. For AI to deliver true value, it must be layered onto a foundation of proven, deterministic logic.

In practice, aPriori’s DFM results come from:

1) The user’s CAD model geometry

- Features, thickness, radii, holes, draft, undercuts, parting lines, etc.

- This is the core “what is being made” input

2) The user’s materials, processes, and manufacturing assumptions

- Process selection (machining, casting, molding, sheet metal, etc.)

- Material choice and its manufacturability constraints

3) The user’s factory/region/supplier and cost model settings

- Labor rates, machine rates, overhead assumptions

- Regional differences and factory capability assumptions

This is what makes the output “your reality,” not generic guidance

4) Optional: the user’s historical PLM/ERP data (if integrated)

- aPriori can connect to systems such as PLM to enhance context (materials, part metadata, routings)

- However, DFM does not require historical data to work

No More Bottlenecks, Greater Ability To Achieve Objectives

Automated DFM analysis, like aPriori’s solution, helps manufacturers not only streamline and accelerate product development but also enhance it. It also provides these benefits:

- Eliminates bottlenecks throughout product development

- Empowers design engineers to focus on priorities

- Accelerates time to market

- Enhances engineering-led earnings before interest, taxes, depreciation, and amortization (EBITDA) impacts

With aPriori, there is no loss of “Design momentum” with fast, precise, and consistent analysis, eliminating the need to wait for data from others, such as suppliers or in-house subject matter experts. Solutions like aPriori remove bottlenecks, eliminate non-value-added activities such as chasing suppliers or setting up design review meetings, and facilitate more efficient, timely product development.

Automated DFM Analysis + AI=Design Efficiency and Optimization

AI can provide you with fast information. Yet, it can’t provide you with real results and return on investment (ROI) the way an automated DFM analysis solution can.

However, leveraging AI in conjunction with an automated DFM solution delivers real value. Combined, this powerful coupling can identify the biggest problems and cost drivers. It can also detect patterns from huge datasets to drive the next phase of innovation.

Stay tuned. aPriori has an exciting new development in the works. Soon, Generative AI will be added on top of our Manufacturing Insights.

Remove Bottlenecks and Streamline Product Development

Our DFM guide shows you how automated manufacturability and cost insights early in the design stage can accelerate product development, reduce costs, and optimize design.