With Accurate, Comprehensive, Fact Based Data for Effective Supplier Collaboration and Negotiation

With supply chains expanding across the globe, demand for high quality products, faster deliveries and cost pressures have increased. It’s no wonder that sourcing managers and buyers are finding it more challenging to ensure orders are placed with the best suppliers that will deliver on time and at the most favorable price. In today’s market, you simply don’t have the time to send an RFQ and wait around for the negotiations to start. The good news is: you don’t have to anymore.

Generate a Detailed Manufacturing Process and Cost Report in Seconds

aPriori enables sourcing managers and buyers to identify the best opportunities for cost savings as well as the suppliers that are best suited to make their parts in the most cost-effective way. aPriori helps you engage your suppliers early in the product development cycle to leverage their manufacturing expertise in a cost collaborative manner so that savings are realized and relationships grow.

Here's how it works:

Seeing is Believing. Request a Demo.

We’ll show you exactly how aPriori works.aPriori Solutions for Sourcing Professionals

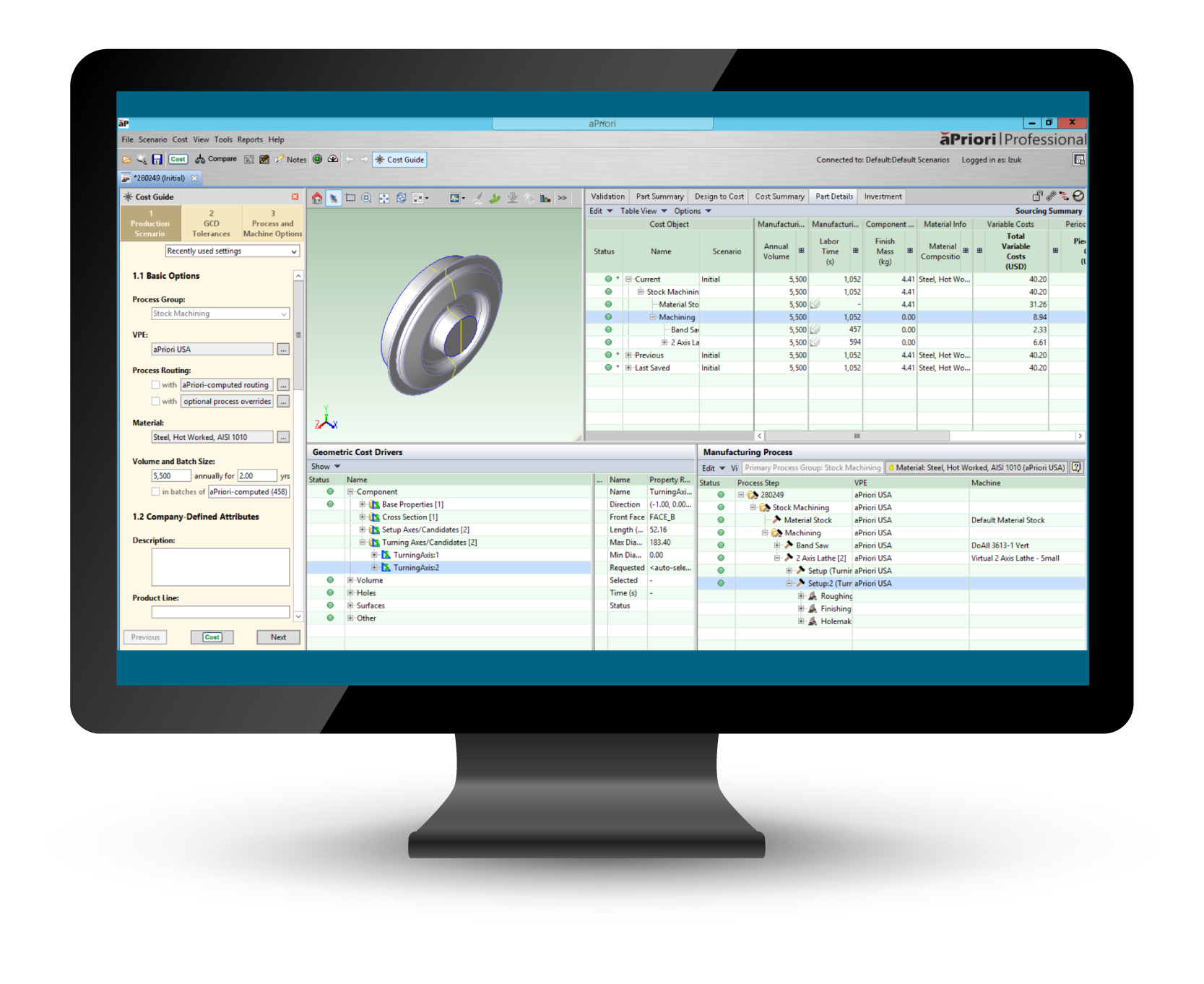

Connect aPriori to your PLM system for automated manufacturing simulation upon check-in of new or modified CAD designs. These initial cost estimates can be refined into a target price.

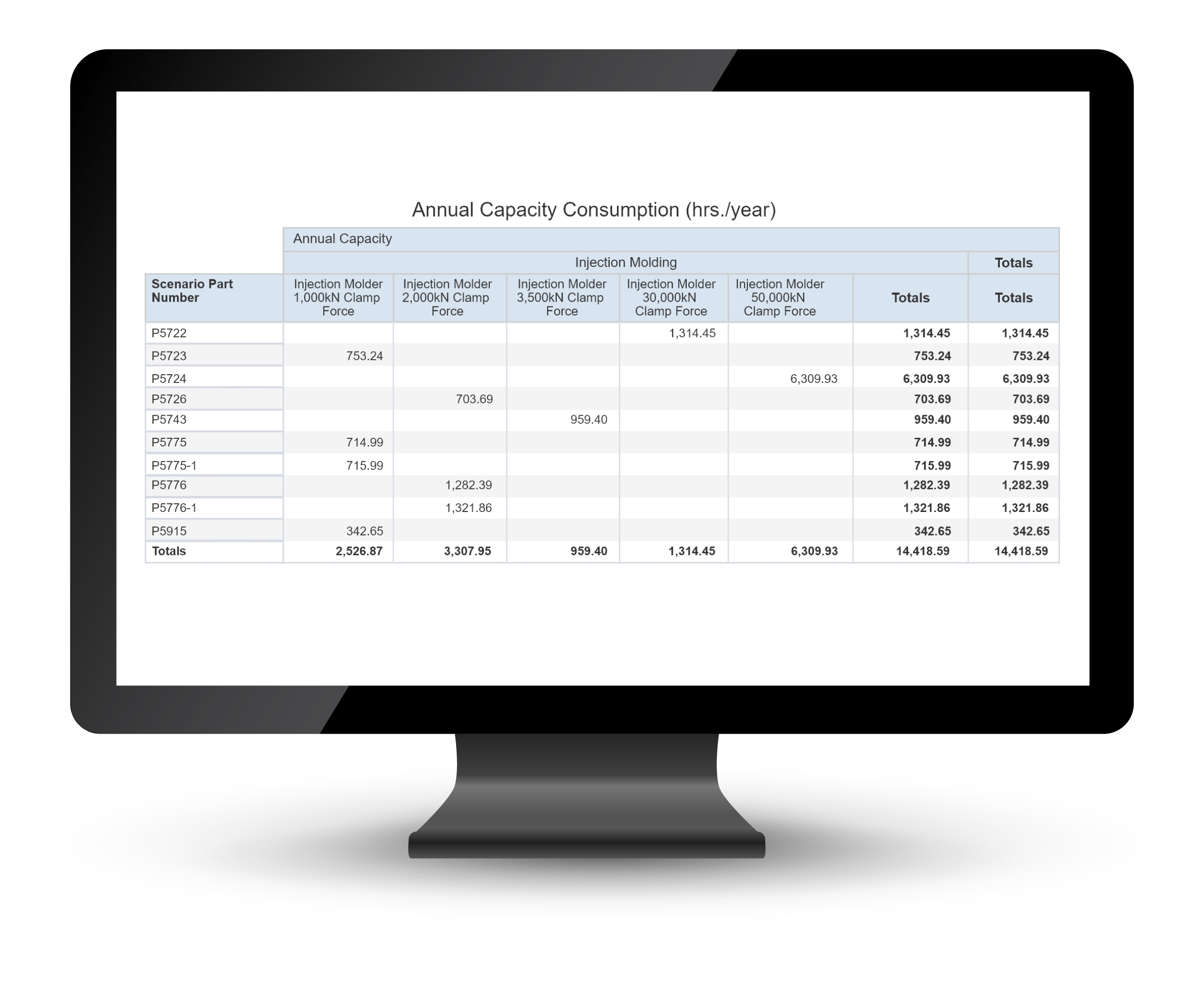

Provide detailed cost data for your parts. Create custom reports to pinpoint parts that have the most potential for savings and generate reports that help you identify and avoid capacity and quality risks.

Generate detailed cost estimates including secondary processes. Simulate the manufacture of your parts to help you conduct more transparent supplier negotiations and better manage supply chain risks.