Key Takeaways:

- Today’s challenges are having an impact on indirect and direct manufacturing costs

- aPriori can identify where to cut indirect and direct costs to boost profitability

The Full Article:

According to McKinsey, indirect operations account for 8%-12% of a manufacturer’s total operating costs. What’s more, the National Institute of Standards and Technology (NIST) noted that in 2021, manufacturing companies added an estimated 24% of gross domestic product (GDP) including direct and indirect value-added costs.

Increased prices (i.e., energy, overhead costs, equipment, materials, services, labor, etc.) necessitate the optimization of indirect and direct manufacturing costs. Doing so ensures resilience, profitability, and growth.

Examples of Indirect and Direct Manufacturing Costs

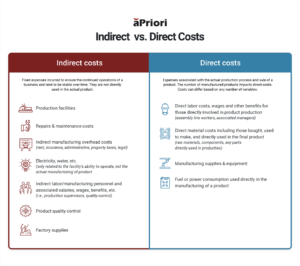

Indirect and direct costs are not one and the same. Note the differences between them in the following chart:

Direct costs are associated with the production cycle, while indirect costs keep the production cycle operating. The cost of materials is an example of a direct cost, while utilities are an example of an indirect cost. Direct costs are used purely in the production of a product. Indirect costs are those used specifically to keep a business running.

Learn how aPriori can help you can avoid rising supply chain prices.

How Indirect and Direct Manufacturing Costs Impact Profitability

The above indirect costs are unavoidable for most businesses. Moreover, they make up a significant portion of businesses’ total manufacturing costs since they are essential to ensuring efficiency in day-to-day factory operations. As a result, it is critical that manufacturers optimize the bottom line.

With ever-increasing prices on everything from materials and services to labor, it is imperative for manufacturers to employ a manufacturing insights solution. Such a solution can identify cost outliers and ensure indirect and direct cost optimization, strengthening resiliency and improving profitability.

Direct manufacturing costs can also affect profitability. Higher prices for materials as well as other expenses related directly to the manufacturing or production of a part can drive up costs. Another example can be found when costing parts. How can manufacturers ensure that they are producing a part in the most cost-efficient manner without sacrificing quality?

Without the right manufacturing insights solution, many manufacturers could be leaving money on the table. The good news is that aPriori accounts for these indirect and direct manufacturing costs and can facilitate better business decisions.

aPriori Identifies the Cost Outliers to Improve Profitability

Manufacturers are under pressure to get to market quickly and ensure profitability. Additionally, they must address challenges such as supply chain issues and labor shortages. aPriori’s manufacturing insights solution can support their efforts and help mitigate many of these challenges. Here are a few ways aPriori identifies and reduces direct and indirect manufacturing costs:

- Product Quality and Cost Control: Product quality in the design stage greatly influences cost. If manufacturability issues are not caught before a design is released, then an engineering change order might be required. Even worse, a defect can cause delivery delays. A digital factory can detect defects prior to production in the physical factory. Product development teams can create lower-cost products without sacrificing quality during the design process. aPriori provides real-time, data-driven insights into cost, design, and manufacturability, providing various materials, manufacturing processes, regional factories, and annual production volume considerations. Unnecessary features can be removed, and design flaws detected. The most cost-effective materials can be used. Time to market as well as product quality control issues and manufacturing overhead are reduced. These Design to Value (DTV) and Design to Cost (DTC) methodologies enable manufacturers to deliver profitable products, maximizing the value of a new product for the end user.

- Supply Chains: Supply chain management, in particular reducing requests for quotes (RFQs) times (an indirect cost), can greatly impact the bottom line. It is especially true in the procurement of raw materials used in products (a direct cost). Depending on the size of the organization and the number of parts needed, RFQs can be time-consuming and labor-intensive. How can you ensure that you are getting the best price for raw materials? aPriori helps navigate supply chain challenges and management. Woodward uses aPriori to assess the cost and manufacturability of parts matching open opportunities within the supplier’s digital factory. Working closely with strategic suppliers enables Woodward to tap into their expertise, control costs, and ensure access to critical materials and components – especially for new product development. Woodward went from a 10-week to a one-week supplier lead time, mitigating their labor shortages and moving from five people down to one person quoting supplier prices.

Utilize aPriori to see how your product cost changes as material rates change.

- Labor shortages: According to Deloitte, US manufacturing is expected to have 2.1 million unfilled positions by 2030. Woodward uses aPriori’s manufacturing insights to help save time for sourcing to quote quickly and with greater accuracy. aPriori digital factories simulate product design and production runs in real-time, automatically providing actionable manufacturability guidance. Development teams can run complex design and production scenarios quickly to determine the best options for cost, materials, and manufacturing processes. Consequently, productivity improves. The McKinsey article substantiates it, noting that streamlining processes and tasks can result in a five to 15% increase in productivity.

Read how Woodward addressed labor shortages and reduced quoting times by nine weeks using aPriori.

The Digital Thread is Key to Reducing Costs and Boosting the Bottom Line

Understanding and anticipating both indirect and direct manufacturing costs can help you forecast expenses more accurately as well as determine where they can be reduced. Identifying reductions via the right manufacturing insights solution can be transformative for an organization.

Manufacturers who recognized this untapped potential and leverage manufacturing insights gain myriad benefits. Most importantly, they reduce costs. They also improve efficiencies, mitigate supply chain and labor challenges, and strengthen their resilience and competitiveness in the marketplace.

Improve Cashflow. This Podcast Shows You How.

Shore up cash reserves to weather any economic storm.