From Collaboration to Confidence: How Engineering Teams Design Smarter and Faster with Insight

Key Takeaways:

- Break the Collaboration Ceiling:

Modern collaboration tools may improve communication but not necessarily innovation. True speed and market advantage come from enabling engineers to make informed, manufacturable, and cost-effective decisions early in the design process. - Empower Engineers with Real-Time Insight:

aPriori embeds automated manufacturing intelligence directly into design workflows, turning every engineer into a strategic decision-maker who can quantify cost, feasibility, and sustainability before reviews occur—accelerating time to market and reducing risk. - Transform Design Efficiency into Enterprise Value:

By automating expert knowledge and connecting engineering data to enterprise metrics, aPriori aligns design, procurement, and manufacturing around a single source of truth—driving faster launches, lower costs, and stronger market performance.

The Full Article

The Collaboration Ceiling

Today’s engineering organizations are more digitally connected than ever. Files move seamlessly across global teams. Comments appear in real time. Feedback loops operate around the clock.

But while modern collaboration tools may accelerate communication, they rarely accelerate innovation. Faster exchanges don’t necessarily translate to better designs—or faster time to market.

Critical design reviews still open with familiar, costly questions:

“Is this manufacturable?”

“Will it meet our cost and margin targets?”

“Do we have the right materials and suppliers?”

By the time those questions surface, schedules have slipped, rework has begun, and opportunities to differentiate in the market have already narrowed. The result is a “collaboration ceiling”—a point where greater connectivity no longer yields better business outcomes.

Leading manufacturers are breaking through that ceiling by rethinking where product development begins. They’re empowering engineers with real-time insights into cost, manufacturability, and sustainability at the moment of design—long before traditional reviews occur.

The payoff is significant: faster product launches, fewer design iterations, and higher confidence that every new innovation will meet market demands, margin goals, and revenue expectations from day one.

Empowering Design Engineers Before the Review

In the race to bring innovative products to market, time and precision are everything. Yet too often, design decisions are made in the dark—based on best guesses rather than real-world insight.

aPriori changes that equation.

By leveraging real-time manufacturing intelligence—comprising digital process models, machine parameters, and regional cost data, alongside the CAD environment, engineers can analyze designs as they create them, without waiting for downstream feedback. This capability enables agile design exploration: testing multiple geometry, material, and process combinations while quantifying the resulting cost, cycle time, and carbon footprint. The result is faster, data-driven decision-making that helps engineers answer critical manufacturability and cost questions in real time, rather than relying solely on expert review later in the process.

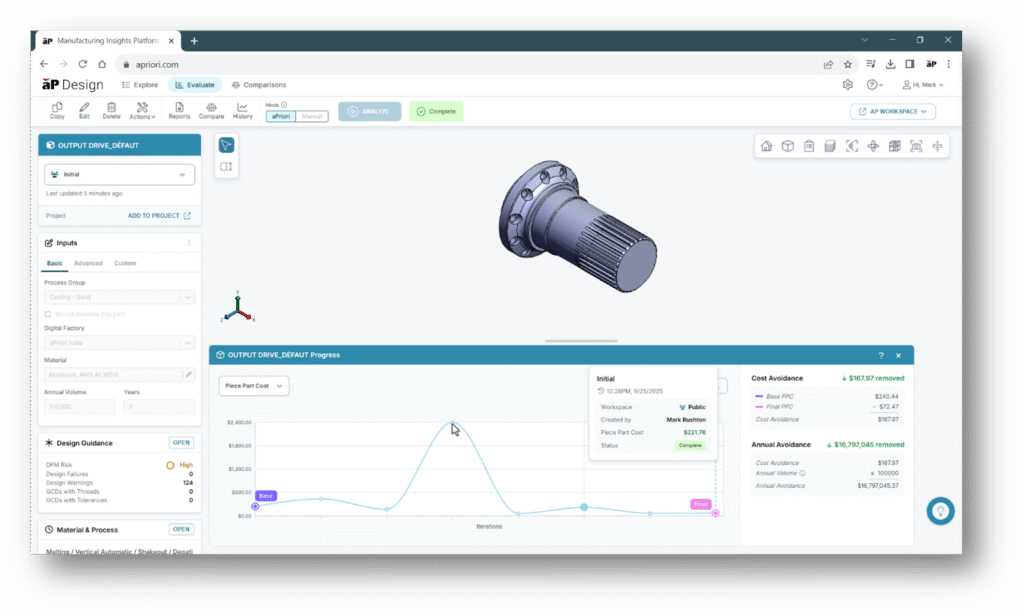

The image below illustrates how an engineer can quickly create an initial baseline analysis and tracks their progress as the design matures, ultimately producing a more cost-effective design without the need for specialized analyst assistance.

No more waiting for downstream feedback. No more late-stage redesigns that drain time, budgets, and momentum. Instead, design teams can evaluate trade-offs in the moment—ensuring every iteration is aligned with business objectives from the start.

With aPriori, every engineer becomes an informed decision-maker, equipped to answer the questions that determine commercial success:

- What’s driving cost in this design?

- Can it be produced efficiently at scale?

- Is there a smarter material or process alternative that accelerates time to market?

Before a design even reaches review, it’s already validated by data—not assumptions. The result is a development process defined by confidence, speed, and strategic alignment—where innovation moves faster, risk is reduced, and market opportunities are captured sooner.

Before and After: The Power of Quantified Insight

Before aPriori

“I modified our existing pump design to handle higher pressure by increasing the diameter by two inches. Can you share this with our supplier? I believe the cost will scale with size.”

A design guided by experience and estimation—dependent on external validation for feasibility and cost accuracy.

Decisions like this often trigger extended review cycles and cost surprises downstream—when teams realize a seemingly simple design change requires a larger press, additional machining operations, or a new fixture setup. These late-stage discoveries not only increase manufacturing expense but also delay prototype builds and production start dates.

After aPriori

“To meet the pressure requirements without resorting to a larger, more expensive machine, I optimized the impeller geometry—using a smaller component with higher RPM, machined from raw steel. It meets performance targets, improves quality, and reduces cost.”

With aPriori, design decisions are no longer speculative—they’re strategic. Engineers gain real-time visibility into cost drivers, manufacturability scores, and corrective guidance, and performance trade-offs as they work. Every adjustment is backed by quantified insight, creating a direct line between engineering intent and business outcomes.

Stakeholders see the financial and operational implications immediately. Reviews shift from debate to alignment, and teams move from iteration to execution with confidence.

The result: faster approvals, lower product costs, and innovations that reach the market first—and win.

Automating Expertise Across the Design Process

For decades, the expertise of seasoned cost and manufacturing engineers has been the key to building products that are profitable, manufacturable, and competitive. The challenge? That knowledge often resides in a few specialists—creating bottlenecks, delays, and inconsistency across design teams.

aPriori changes that dynamic. Its embedded intelligence delivers the insights of experienced cost and manufacturing experts directly into the hands of every designer. Models are automatically evaluated against real-world production data, identifying risks and opportunities at the earliest stages of development.

Design teams can run bulk and overnight analyses across entire assemblies, accelerating workflows and eliminating dependency on manual review cycles. Senior engineers are freed to focus on innovation and strategic challenges—rather than repetitive validation tasks.

Every engineer becomes a better engineer—faster.

The impact of aPriori extends far beyond the CAD environment. By directly connecting design choices to enterprise metrics—such as time to market, cost reduction, manufacturability, and sustainability—organizations transform engineering efficiency into measurable business performance.

With aPriori, design, manufacturing, cost engineering, and procurement all operate from a shared, data-driven source of truth. The result is alignment across functions, reduced friction in decision-making, and a clear line of sight from product concept to profitability.

This isn’t just engineering optimization—it’s enterprise transformation.

Streamlining Cross-Functional Collaboration

When design intelligence stays siloed, downstream teams are left reacting instead of planning. aPriori closes that gap by giving every stakeholder—from manufacturing engineering to sourcing—access to the same real-time insights that guided design decisions.

Now, downstream teams can contribute earlier and more strategically. Manufacturing engineers can anticipate the production impact of design choices, understanding the required machine capacity, tooling needs, and process constraints well before parts reach the shop floor. Instead of discovering later that a design needs a larger press or additional setup time, they can plan capacity, optimize workflows, and avoid costly last-minute adjustments.

Sourcing teams benefit too. With target costs generated automatically from digital manufacturing simulations, they gain a clear benchmark for supplier quotes. This enables them to identify the most competitive suppliers more quickly, negotiate with confidence, and establish fair, data-driven pricing that aligns with design intent.

The result is a seamless, cross-functional handoff where design, manufacturing, and sourcing teams operate from a shared foundation of truth. What was once a linear, reactive process becomes an integrated, proactive collaboration—accelerating time to market and amplifying enterprise-wide value.

From Collaboration to Creation

The future of product development isn’t defined by how well teams communicate, but by how intelligently they create.

aPriori empowers engineers to make confident, cost-informed, and sustainable design decisions from the start—turning what was once guesswork into a strategic advantage.

The difference is profound.

One approach helps you talk about your designs.

The other helps you transform them.

Check Out This Case Study from Dana Off Highway Vehicles

Dana Saved Millions by Implementing DFM Early in the Design Lifecycle

More Resources:

- Want to Try aPriori for Free? Check out aPriori Academy

- Blog: How Target Costing Can Be Accelerated by Design Engineers

- Video: How Automated Digital Manufacturing Is The New Digital Transformation

- Blog: Turbocharge Your Product Profitability: How Manufacturing Intelligence is Fueling Growth for Modern Manufacturers