Automated Should Cost: Achieve Product Development Speed & Cost Targets

Key Takeaways:

- Today’s volatile, hyper-competitive markets require more speed: faster product development, costing, decision-making, and time to market

- Automated should cost analysis enables engineers to get critical data-driven insights quickly to accelerate product launches and improve cost targets more efficiently

- It also enables them to focus on priorities and address the most critical issues, rather than get mired down in minutiae

The Full Article:

What causes multi-billion-dollar companies to launch new products and existing product improvement projects late and over cost targets?

Your engineering team has devoted countless hours to working hard on a challenging new product development project. However, with the finish line in sight, you realize that your costs have exceeded their target.

It is a critical juncture that can necessitate a tough decision for the engineering team and the broader product launch team. Should you proceed with the product launch above the projected cost targets and compromise on profit margins? Or keep critical customers happy and adhere to the agreed-upon initial timelines? Even more crucial, how do you avoid this scenario in the future?

Figure 1: You shouldn’t have to decide between getting to market faster and meeting margins/cost targets

Automated Should Cost Analysis: Time To Market, Cost Target Realization, & Profit Margins

Achieving all of the above shouldn’t be an either/or proposition. Design engineers can achieve both margin and revenue goals by accelerating product cost estimation at the individual parts and assembly levels.

What Is Should Cost Analysis?

Should cost analysis estimates a product’s cost. Some critical factors to consider it’s applicability include whether the part is brand new, a modification of an existing part, or an existing production part to be reused. It’s also helpful to know whether it will be outsourced or made in-house.

For existing parts intended to be reused in other products, there might be sufficient data to accurately identify the “should cost” as real production and supply chain costs exist already. However, on new parts or existing part redesigns, there’s often no baseline and it becomes challenging to predict or estimate what the cost should be.

Instead, teams must determine a new approach to should costing where no previous data exists without impeding the product development process timeline. Typically, there is no quick and easy solution when the team needs new information to determine the should cost and is reliant on others for it.

With externally sourced parts, there is often less data available in-house. More scrutiny is needed to validate the assumptions, such as cycle time and the type of manufacturing process.

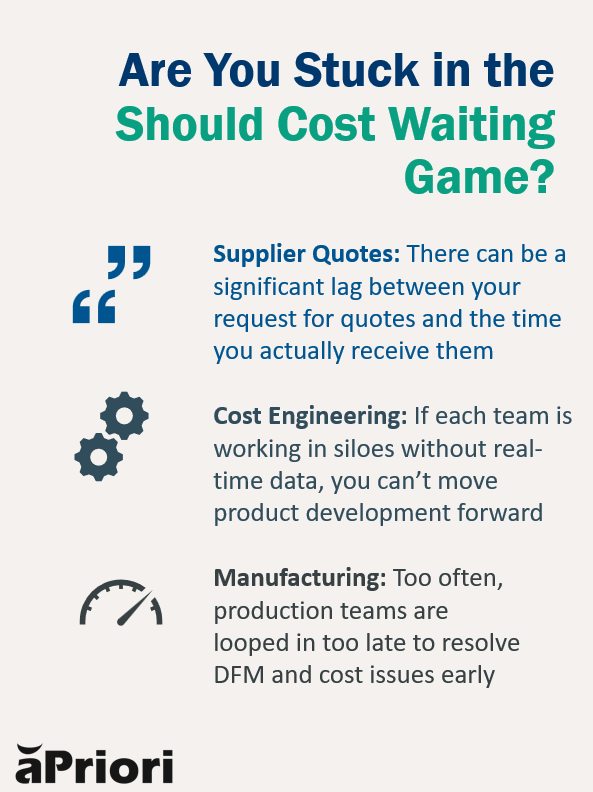

Figure 2: Traditionally, should costing can become a waiting game. Relying on multiple people and processes can impede product development and time to market.

There are multiple moving parts, including people and processes, which lead to prolonged design review periods, multiple iterations and loops, missed deadlines, increased personnel costs, and ultimately, unhappy customers. Moreover, this is especially true when there are many and/or complex parts involved, as we start to see a compounding effect.

But there is a transformative solution: Automated 3D-CAD Should Costing.

Automated Should Costing: Estimate Faster & More Accurately So You Can Focus On What Matters Most

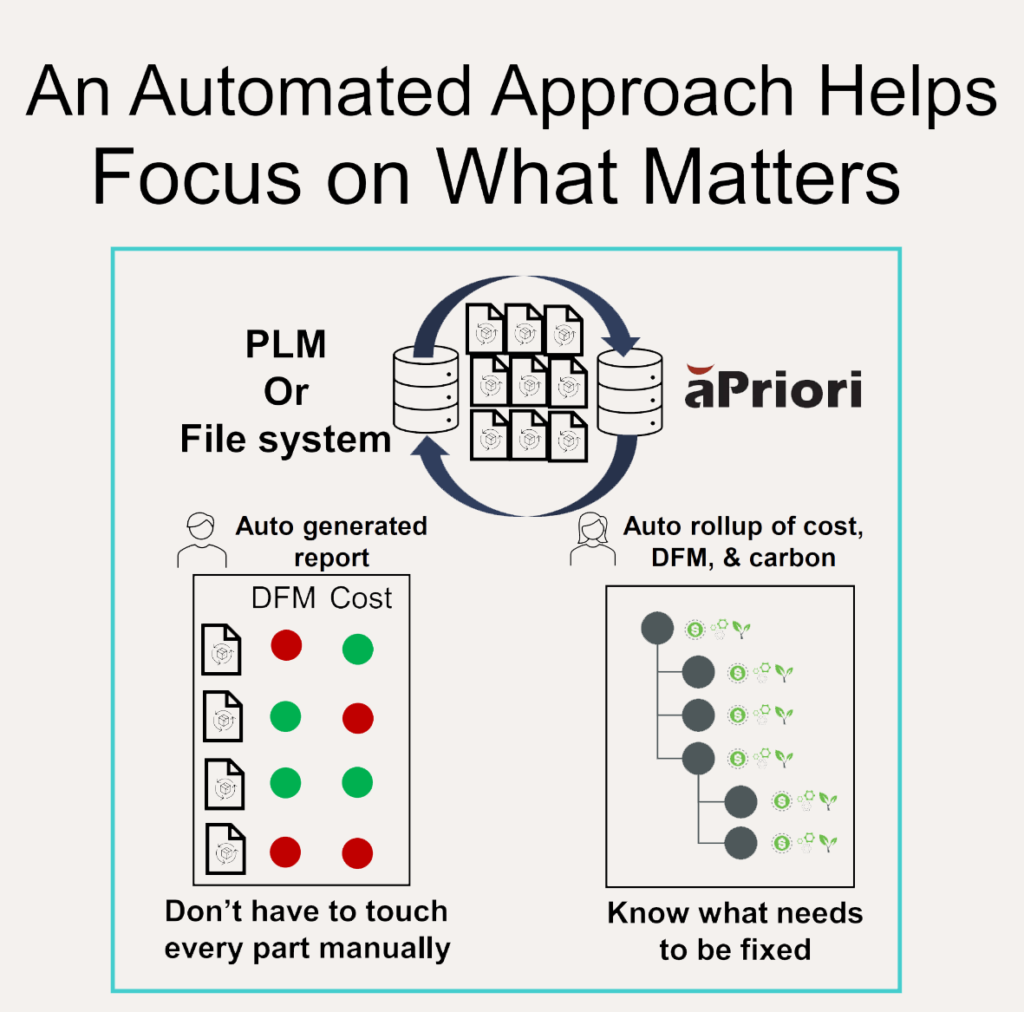

Automated should cost analysis using 3D-CAD expedites the process. No longer do engineers have to scrutinize every part with a fine-tooth comb to figure out whether it is above or below the cost target. Now, teams can work smarter, not harder, by letting an automated should cost engine analyze parts as they are checked into product lifecycle management (PLM) system.

Products reach the market more cost-effectively and quickly. Design engineers can be confident in the accuracy of the data and assured that they will achieve cost targets and meet launch deadlines. Here’s how it works.

Figure 3: Automated should costing can analyze many parts at once, detailing DFM issues, cost issues, or both, early in product development.

Defining Automated Should Cost Analysis

Instead of engineers analyzing parts one by one, the automated should cost engine automatically analyzes many parts without the engineer having to look at each one. They can now receive a report that indicates which parts require improvement. For example, a designer checks a part into a PLM system. Behind the scenes, the CAD model and metadata are pulled automatically, analyzed, and a report is generated. That designer receives a report detailing exactly what needs attention—DFM issues, cost issues, or both.

At the same time, costs, carbon, manufacturability, and cycle time can be rolled up automatically. By integrating with PLM—or even file-based systems—a human touchpoint can be eliminated, and insights delivered directly to the people who need them.

Automated Should Costing with 3D CAD Enables High-Velocity Product Development

aPriori’s automated should cost analysis is a simulation-driven approach that determines the “true” manufacturing cost of a product by directly analyzing 3D CAD models. Unlike traditional methods that rely on historical data or manual spreadsheets, aPriori uses a physics-based engine to simulate the entire production process within a “digital factory.” By factoring in geometric complexity, material properties, cycle times, and regional variables, it generates granular, bottom-up cost estimates in minutes, using the following features:

1. Geometry-Driven 3D-CAD Analysis Makes Should Costing Fast & Objective

aPriori eliminates the “rearview mirror” approach of relying on historical or existing cost data. aPriori’s digital twins calculate costs instantly from 3D CAD models, moving organizations from subjective “expert opinions” to objective, physics-based data.

2. Manufacturing Process Optimization + Regularly Updated Data

aPriori extracts geometric features from CAD files to determine the manufacturing methods available to realistically make the part. By combining the optimal manufacturing process with regularly updated Regional Data Libraries (RDLs), which include updated global labor rates, overhead, and tool costs across 93 regions, a should cost can be generated with full fidelity in the assumptions around it.

Key Benefit: aPriori Enables Continuous Optimization with Automated Should Cost

aPriori’s capabilities can identify manufacturability issues and drive down costs.

As a result, manufacturers can remediate them and optimize product development more quickly and cost-effectively. In fact, aPriori customers often report a 10-20% direct material cost savings.

By automating the “should cost” process, aPriori enables continuous optimization, allowing companies to scale their cost engineering efforts across the entire enterprise rather than just on a few “strategic” parts.

The Proof Point

Customer: CNH, a multi-billion-dollar industrial and agricultural equipment manufacturer.

Challenge: Launching on time and under the cost target. This year alone, they’ve identified $10.2 million in cost avoidance using automation.

Solution: aPriori’s automated should cost analysis solution enables CNH to identify and focus only on the necessary parts. For example, it provides:

- Should costs creation for a higher percent of the Bill of Materials (BOM)

- aP Workspace eliminates siloes and disconnects, enabling engineering to loop in experts when more detailed reviews are needed, or share information and trace it with procurement teams

- Engineering cost avoidance is streamlined with standardized dashboards through automated should cost analysis. Early engineering cost impact can be quantified with automatically generated data, including potential avoidance, each team’s usage, analyzed value tracking, and optimization trends over time

Automated costing runs automatically every time a baseline or step release is created. We don’t have time to touch every part manually, but we still get live cost rollups. If a part comes back with a medium or high manufacturability risk, then we dig deeper. It also helps when choosing between multiple design concepts that meet customer requirements—which one is the better cost?” —Ryan Figgins, CNH Global Chief Engineer

Discover how CNH launches on time and under cost with aPriori.

“If you haven’t explored what aPriori can do, go seek it out. Remove barriers to execution in your daily work.” CNH

Embrace Automated Should Costing Or Be Left Behind

Automated should costing enables product development teams to accurately understand, predict, and control costs. This more expedient method means design engineers can focus on what matters most, including innovating better, faster, and more frequently.

Decision-making is expedited and more informed, often reducing the cost insights timeline from weeks to hours, even minutes. The choice is clear: embrace automated should costing or be left behind.

Do You Know What Your Should Cost Should Cost?

Calculate purchased product cost targets more accurately. Then leverage them to conduct more effective, fact-based supplier negotiations, reducing costs, accelerating time to market, and fostering smarter design.