Adapt, Quote, Win: Strengthening Supply Chain Resilience in a Shifting Global Landscape

Key Takeaways:

- Manufacturers need every competitive advantage in reducing supply chain risks and creating supply chain resilience to ensure business continuity

- Automation and predictive analytics can facilitate an agile supply chain that helps mitigate vulnerabilities and improve responsiveness

The Full Article

With tariffs becoming more prevalent, selecting the best-cost country has become a crucial factor for manufacturers’ global supply chains. This shift increases the demand on suppliers, presenting both opportunities and challenges.

On the one hand, suppliers can be more selective with the work they take on and adjust pricing margins based on demand. On the other hand, they must quickly assess and respond to RFQs (Requests for Quotes) that offer the highest profitability.

While perhaps not immediate in the US, a near-term plan for OEMs might be to move production into the US. Suppliers need to think about how they will handle increased demand for quotes and the ability to keep production running efficiently while capacity increases. Suppliers in the EU might not be as concerned with tariffs unless they have customers in the US. They may be thinking of their partnerships with suppliers in low-cost countries where demand is becoming greater and, therefore, prices have become higher.

Additionally, teams must manage capacity effectively, ensuring seamless communication between sales and production. Questions arise, such as: Do we have the production efficiency to handle this work? Should we invest in equipment to enhance productivity or meet increased demand? aPriori provides tools to help manufacturers navigate these challenges and maximize profitability.

Selecting the Most Profitable Work

aPriori helps manufacturers evaluate the parts they’re currently producing for customers—pinpointing cost drivers that are eroding margins, assessing the impact of tariffs, and identifying opportunities to optimize production. With these insights, teams can renegotiate contracts, justify necessary price increases, or find more cost-efficient ways to manufacture the same parts.

With aPriori, manufacturers can:

- Respond to RFQs faster: aPriori analyzes equipment, processes, and factory strengths to recommend the best production methods. It provides insights into costs, cycle times, capacity, and machine utilization, removing bottlenecks and ensuring an efficient and cost-effective approach.

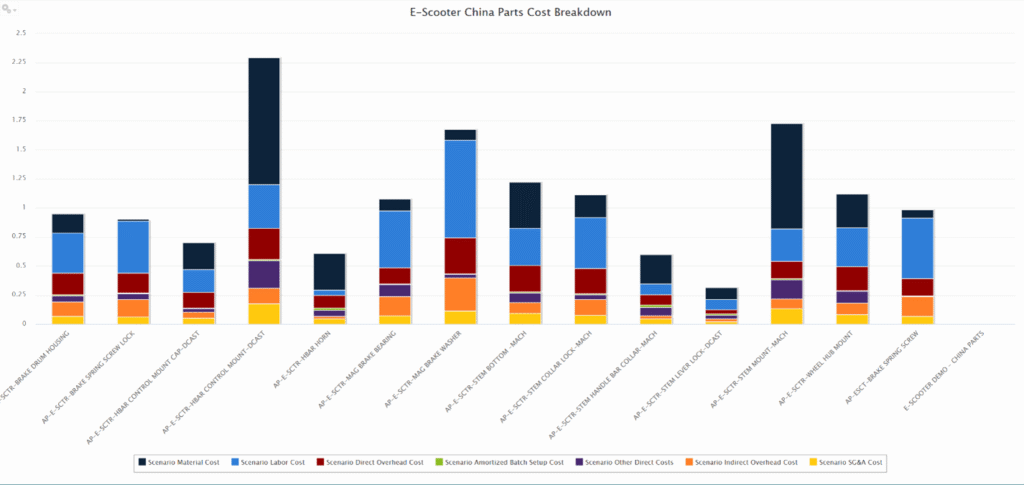

- Optimize pricing strategy: aPriori enables manufacturers to compare production costs and pricing across different regions and facilities—including scenarios with and without tariffs. This allows them to evaluate whether parts should be produced locally or offshore, set more competitive and realistic pricing, and respond more effectively to customer demand while protecting margins.

- Leverage digital factories for regional analysis: Out-of-the-box regional Digital Factories help manufacturers assess their competitiveness in the face of tariffs, ensuring strategic pricing and cost planning for quoting.

Capacity Planning: Maximizing Profitability

Proper capacity planning is essential to maintaining profitability in the face of unexpected events and a fluctuating trade environment. aPriori provides data-driven insights that help manufacturers:

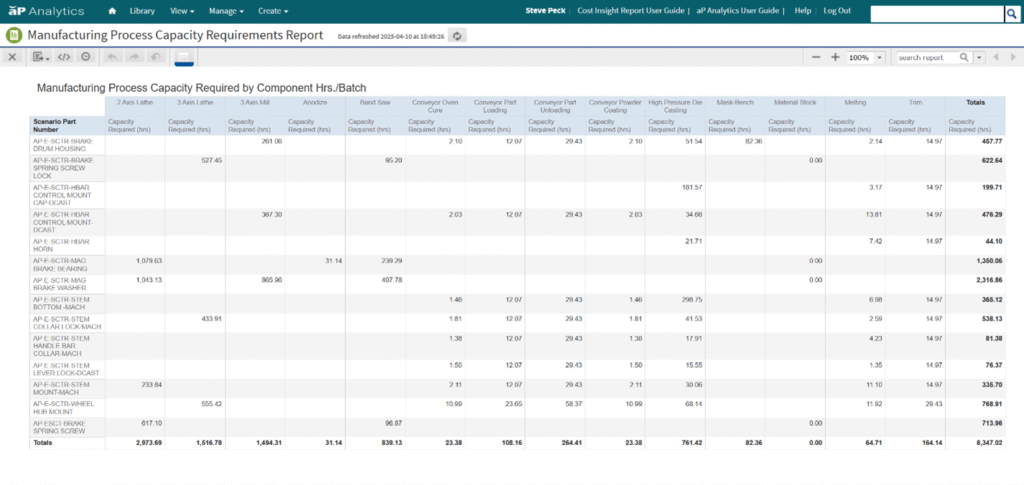

- Decide whether to produce in-house or outsource: By analyzing capacity and part-specific requirements, manufacturers can efficiently allocate resources such as raw materials, reduce delays, and protect profit margins.

- Model financial impacts: aPriori helps manufacturers evaluate the effects of options like overtime or subcontracting, ensuring they meet tight deadlines while maintaining profitability. This flexibility minimizes financial trade-offs and enhances cash flow.

Enhancing Collaboration Between Sales and Production Teams

Effective communication between sales and production teams is essential to managing capacity efficiently. aPriori supports collaboration by:

- Allowing sales teams to provide rough production estimates, enabling production teams to confirm capacity quickly and in real time.

- Helping teams forecast future capacity demands with greater accuracy, preventing bottlenecks, overcommitments and ensuring efficient resource allocation.

Justifying Capital Investments With Stakeholders for Greater Efficiency

Manufacturers must strategically evaluate investments in equipment and technology to improve production efficiency to keep pace with demand. aPriori helps manufacturers:

- Assess the number of machines required to complete workloads on a weekly, monthly, or annual basis.

- Determine whether investing in new machines will increase efficiency and reduce production costs.

- Analyze the impact of cutting-edge technology on production capabilities, identifying whether new capital investments will speed up processes, reduce manual effort and redundancy, or enhance material efficiency.

Tariff Resilience Ensures Competitiveness

In the face of tariffs, discrete manufacturers must adopt resilience strategies to remain competitive. With digital transformation solutions like aPriori, manufacturers can accelerate RFQ responses, optimize capacity planning, improve collaboration and decision-making, and justify capital investments with data-driven insights.

By leveraging these capabilities, manufacturers can make informed decisions that enhance profitability, improve efficiency and resiliency, and drive sustainable growth in an unpredictable trade landscape.

Handle Trade Barriers and Minimize Risks

See how advanced, data-driven solutions like aPriori can help navigate tariff issues and empower sourcing and procurement teams to identify risks, consider alternatives, and minimize costs