Applying Smart Manufacturing to Boost Profits

Key Takeaways:

- Digital twins can unlock performance and profits in smart manufacturing systems

- Smart factories can meet manufacturability, cost, and sustainability goals while providing the visibility to address risk proactively

The Full Article:

The global smart manufacturing market reached nearly $250 billion in 2021 and is anticipated to exceed $650 billion by 2029, according to Statista. The smart manufacturing term covers technologies that streamline production and help to improve performance (and profitability) and range from data analytics to forecast demand to robotics that accelerate production.

A recent survey of 1,350 manufacturers revealed that 97% intend to leverage “smart” technology in their processes. However, almost two times as many respondents said they lacked the technology to outpace the competition, compared to last year’s survey. And more than two-thirds of manufacturers believe technology can be very /extremely helpful in addressing workforce challenges.

Though manufacturers know that digital adoption is important, concerns abound regarding cost, complexity, training, and potential delays. To address these risks, successful smart manufacturing strategies are incorporating digital twins to get more value from the product lifecycle. Not only can companies augment existing capabilities, but they also can delve deeper to gain further data and insights across all product development departments.

Leverage Smart Manufacturing via Digital Twins to Get More Value

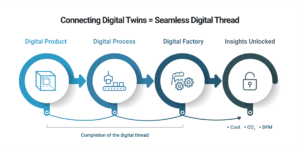

Manufacturers are using multiple types of digital twins to simulate and optimize product designs, manufacturing processes, and specific factory capabilities.

The digital product twin is a 3D CAD model or virtual representation of a physical product to optimize design via simulation/modifications. The digital process twin determines the most effective product manufacturing method. Companies simulate manufacturing processes using the digital twin to identify the most appropriate production process for cost, sustainability, and manufacturability.

The digital factory twin, or smart factory, is a virtual model of the physical factory with factory-specific production capabilities and detailed costs – including labor, electricity, materials, and overhead rates. A digital thread links insights from existing systems (e.g., CAD, PLM) and multiple digital twins to address business goals holistically such as profitability, manufacturability, and sustainability.

Digital Twins Drive aPriori Customers’ Innovation and Profitability

Let’s explore the benefits of a smart factory in creating a more agile, innovative, competitive, and profitable organization for the long term:

- Gain early insights with design simulation. The digital product twin allows design engineers to identify design issues in the early stages. It enables them to put the design through several iterations via simulation to test and analyze it for performance and optimization before sending it to physical production. As a result, physical prototypes and engineering change orders (ECOs) are reduced and a better design is determined. The product can move quickly to production while meeting cost and manufacturability goals. Manufacturers can innovate faster and more frequently, accelerate time to market, and improve the bottom line.

Smart factories, and in particular the digital twins, are fertile ground for product development lifecycle optimization. Manufacturers can create a better product, more cost-effectively. As a result, they can get to market faster and accelerate profitability. Smart manufacturing solutions like aPriori confirm these benefits. Recently, Forrester interviewed four individual aPriori customers. The results were astounding.

Smart Factories: A Manufacturer’s Greatest Partner

Increase Product Manufacturability, Profitability, and Sustainability.

Discover why the digital factory is a manufacturer’s greatest ally