Never Send Another RFQ Again. Quoteless Sourcing Reduces Timelines from 10 Weeks to One Week

Key Takeaways:

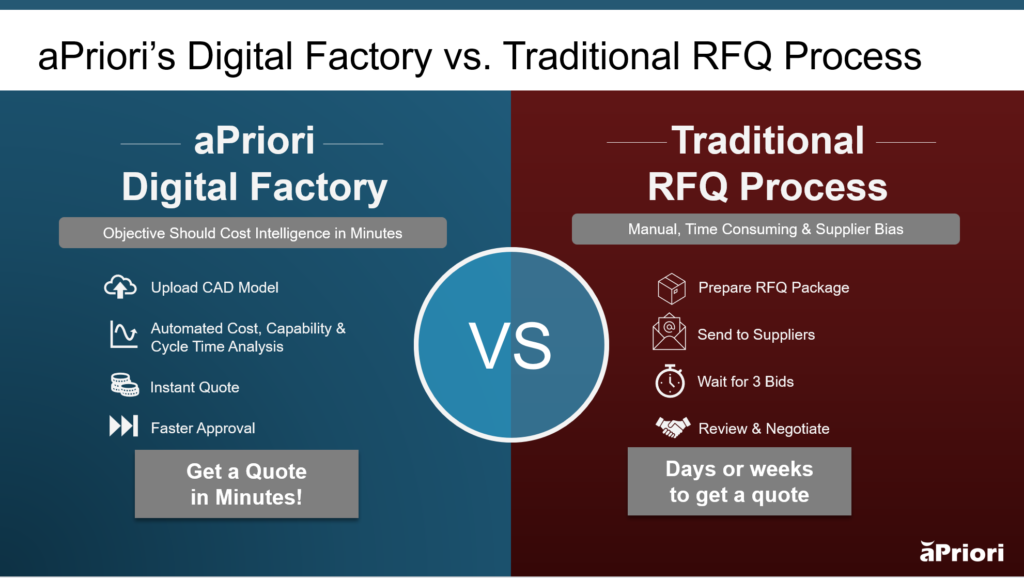

- Traditional Request for Quotes (RFQs) are time-consuming and hinder teams’ ability to dispute suppliers’ cost assumptions, impacting the organization’s ability to meet strategic objectives

- RFQs arrive too late in the process after designs are locked, often setting unachievable cost targets and longer sourcing cycles

- Instead of reactively looking for a supplier to quote a part, manufacturers need to proactively know who can realistically manufacture it as well as its cost, lead time, etc.

The Full Article

Never Send Another RFQ Again

How Quoteless Sourcing is Shrinking Sourcing Timelines by 10X

For most procurement leaders, the idea of never sending another RFQ sounds unrealistic, even irresponsible. RFQs have been the backbone of sourcing for decades. They are familiar, accepted, and deeply embedded in how manufacturing organizations make decisions.

And yet, many of those same leaders are facing a hard truth: RFQ-driven sourcing is no longer compatible with the speed the business now demands.

Across discrete manufacturing, sourcing timelines that routinely stretch out many weeks are increasingly out of step with product development cycles, capacity planning needs, and executive expectations. Engineering is moving faster. Operations is under pressure to lock in supply earlier. But sourcing is still waiting on quotes.

This is where no quote or quoteless sourcing enters—not as a radical rejection of discipline, but as a recognition that the fastest sourcing organizations no longer rely on RFQs as their primary benchmarking engine.

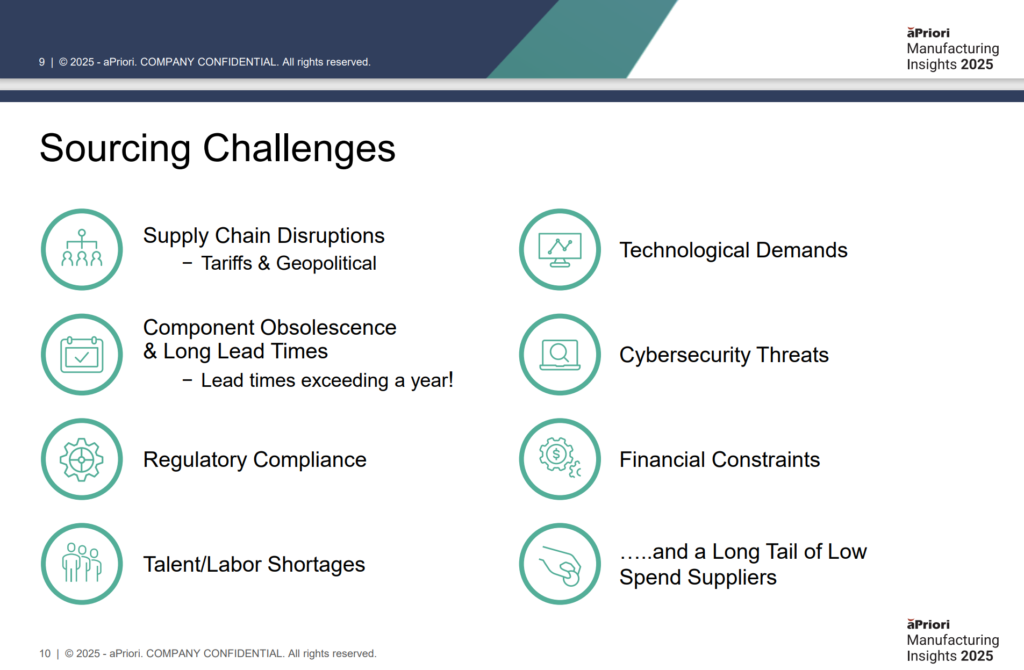

Figure 1: Examples of sourcing challenges faced by Woodward prior to implementing quoteless sourcing

When RFQs Become the Long Pole in the Tent

A manufacturer can have a mature sourcing process and strong supplier relationships. However, they won’t necessarily accelerate the RFQ process. Often, a typical part-level sourcing event can take eight to 10 weeks, from RFQ release to award. Multiple suppliers can bottleneck this process, leading to back-and-forth email exchanges that exacerbate the lag. If design intent is misinterpreted by the supplier, it can stall the product development process, requiring clarification, securing a supplier that can meet the design needs in terms of materials, capacity, and cost, and obtaining a quote quickly.

Supplier quotes often arrive at different times, based on different assumptions. By the time issues surface, including manufacturability concerns, unexpected lead times, and capacity constraints, engineering decisions are already locked in.

While execution, including tighter timelines, clearer RFQ templates, and more follow-up, can help to streamline the process, the gains will likely be marginal. The real problem isn’t necessarily the RFQ process itself. Instead, it is frequently the RFQ that specifically determines the outcome and timeline.

Too often, RFQs are used to discover cost, feasibility, and lead time, rather than to confirm them.

The Hidden Cost of Waiting to Ask

Supplier responsiveness isn’t always the cause of sourcing delays. It is often a result of information asymmetry.

Instead of asking and answering such questions as:

- Can this supplier actually make the part?

- What should it cost, given the process and region?

- What is a realistic cycle time, not an optimistic one?

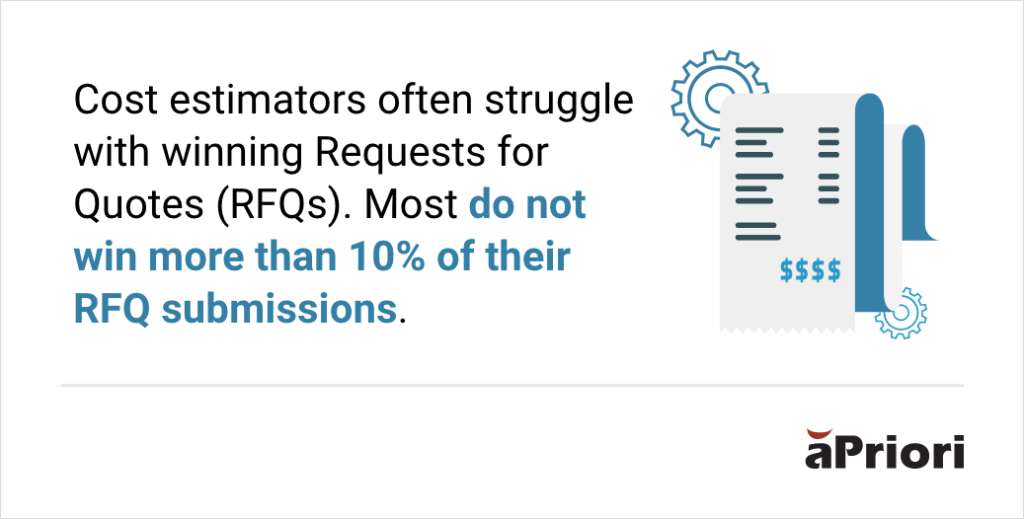

Buyers regularly rely on suppliers to provide the answers.

By outsourcing those answers within the RFQ process, sourcing timelines can balloon. Decisions get deferred. Potential risks surface too late. Moreover, suppliers often spend enormous effort quoting work they have little chance of winning.

The result is that the sourcing function is time-consuming and slow.

Never Send Another RFQ Again (At Least Not First)

This mindset shift can be a pivotal moment for sourcing: What if RFQs were no longer the starting point?

Instead of starting with “Who can quote this?”, the sourcing team can start with manufacturing intelligence. By adopting a quoteless sourcing model, buyers gain early visibility into cost, capability, and capacity—before engaging potential suppliers.

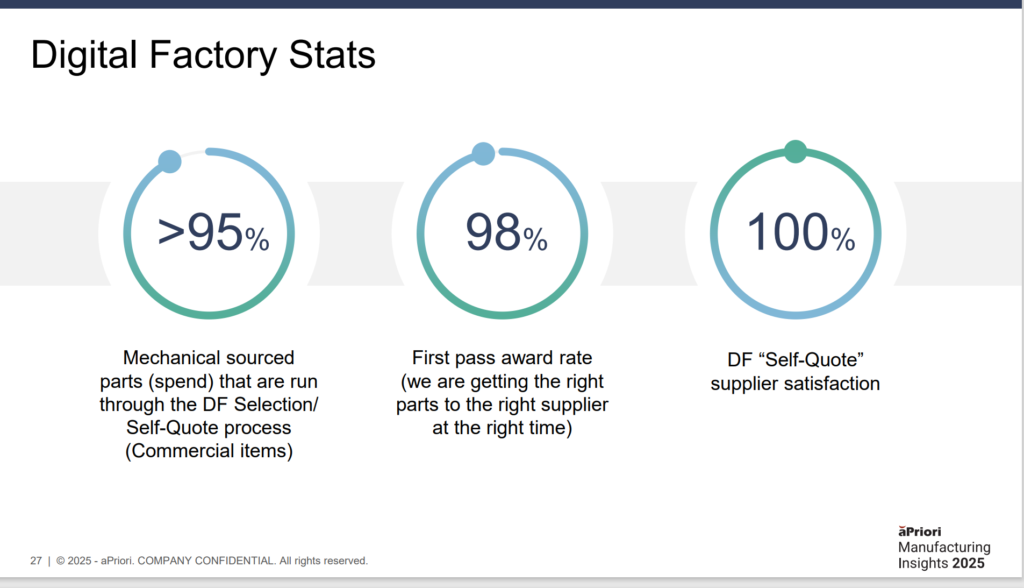

Using aPriori’s digital factories, sourcing teams can model how a part would actually be manufactured, incorporating machines, cycle times, processes, labor, overhead, and regional economics.

Automated should-cost models replace spreadsheets and tribal knowledge. Routing and feasibility analysis confirm manufacturability. Cycle-time and throughput modeling expose realistic lead times and capacity risk.

With those answers in hand, sourcing decisions that once took 10 weeks could be made in one week—sometimes less.

RFQ processes probably won’t disappear entirely. But they are no longer the gatekeeper. Now, they are targeted validation tools, used selectively and intentionally to guide transparent discussions and ensure fair pricing.

Sourcing: From Reactive to Predictive

The impact of moving from quoting to knowing will be immediate and structural.

Buyers no longer need to issue five RFQs to find one viable supplier. They can conduct supplier selection only with those who have already been cost-, capacity-, and capability-qualified. Negotiations accelerate because both sides start from shared assumptions. Late-stage surprises decline because feasibility and lead time have already been tested digitally.

Suppliers notice the difference as well. RFQs are reduced—but far more relevant and rewarding. Win rates improve. Cost estimating teams spend less time quoting non-winnable work and more time planning and executing production. Relationships shift from transactional bidding to purposeful collaboration.

What emerges is a sourcing process that moves at the speed of the business.

For procurement and supply chain leaders, the most powerful outcome isn’t just efficiency—it’s control. By eliminating unnecessary RFQ cycles and gaining immediate access to this intelligence earlier , sourcing timelines collapsed from eight to 10 weeks to roughly one week for many decisions. Programs move faster. Cost predictability improves. Supplier capacity is secured earlier, with fewer fire drills. Just as important, the procurement team’s role changes. Instead of being perceived as a necessary delay, sourcing becomes a strategic accelerator—bringing clarity and confidence earlier in the lifecycle. Figure 3: An example of how Woodward benefitted from supplier-specific digital factories, enabling them to simulate, analyze, and optimize new product designs for cost, sustainability, and design for manufacturing (DFM), including on parts, cycle times, and processes that factor into supplier quotes. This isn’t about abandoning rigor or cutting suppliers out of the process. It’s about recognizing that in a modern manufacturing environment, waiting weeks to learn what you could know in days is no longer acceptable. Quoteless sourcing allows procurement leaders to reserve RFQs for when they add value—not when they are the only way to get answers. It replaces reactive quoting with predictive decision-making and turns sourcing from a bottleneck into a competitive advantage. The fastest sourcing organizations aren’t sending more RFQs. They’re sending fewer—and deciding sooner. Never send another RFQ again doesn’t mean sourcing without discipline. It means sourcing with intelligence, and that’s how timelines shrink from 10 weeks to one.From 10 Weeks to One Week: The Executive Impact

The Real Meaning of “Never Send Another RFQ Again”

Accelerate Quoting, Gaining More Accurate Pricing & Increasing Win Opportunities

Harness manufacturing intelligence to optimize the quoting process. See how it can drive faster, more accurate quotes, while enabling the development of more strategic, collaborative customer relationships.