The Missing Pulse: Reviving Your PLM from Flatline to Lifeline

Key Takeaways:

- Protect Your Investment – A PLM system without real-time data quickly becomes a liability, driving rework, delays, and margin erosion.

- Enable Data-Driven Decisions – Continuous manufacturability, cost, and sustainability insights transform PLM into a proactive decision-making platform.

- Deliver Strategic Outcomes – Organizations realize measurable gains in profitability, speed-to-market, and sustainability by giving PLM a constant “pulse” of actionable intelligence.

The Full Article

The Missing Pulse: Reviving Your PLM from Flatline to Lifeline

In the world of modern manufacturing, the Product Lifecycle Management (PLM) system is designed to be the backbone of innovation — a central nervous system that connects every facet of design, engineering, and production. Companies invest millions in these sophisticated platforms, envisioning them as the single source of truth that will streamline processes, foster collaboration, and accelerate growth.

Yet, for many, this critical investment is flatlining. The initial promise gives way to a frustrating reality: a static database that grows more obsolete with each passing day. Like a heart monitor showing a steady, unnerving line, a PLM system without a constant, revitalizing flow of real-time data stagnates. Its potential remains unrealized, its data becomes untrustworthy, and its value diminishes until it’s seen as more of a burden than a benefit.

A PLM system is not a digital filing cabinet to be set up once and occasionally referenced; it is a living ecosystem that requires constant nourishment. Without it, the “single source of truth” becomes a collection of outdated assumptions.

The Diagnosis: Symptoms of a Stalled System

When a PLM system lacks a pulse of fresh data, the symptoms manifest as a slow, creeping paralysis across the entire organization, creating friction, inefficiency, and costly missed opportunities. The root of the problem is data latency. The design captured in the PLM system and the manufacturing reality on the factory floor begin to drift apart. This digital disconnect occurs for several reasons: engineers work with locally saved files, supplier cost data is only updated quarterly, and feedback from manufacturing is communicated using emails and spreadsheets rather than being integrated back into the system.

The consequences are severe. Design teams operate in the dark, making crucial decisions about geometry and materials based on cost models that are months out of date. This leads to the most dreaded phase of product development: expensive, time-consuming rework. The handoff from design to manufacturing becomes a bottleneck, marked by endless back-and-forth cycles to address designs that are simply not feasible or cost-effective to produce with current tooling or processes.

This disconnect inevitably leads to budget-breaking cost overruns that destroy profit margins. Innovation grinds to a halt as engineers — the very people hired to create the future — are bogged down in administrative loops, trying to reconcile conflicting information and fix preventable problems. Corporate sustainability goals become hollow promises, impossible to achieve without granular, real-time, product-level data on material usage, manufacturing energy consumption, and carbon footprint. Ultimately, the organization is trapped in a reactive state, constantly fighting fires sparked by stale data instead of proactively designing for success.

The Solution: A Pulse of Actionable Insight

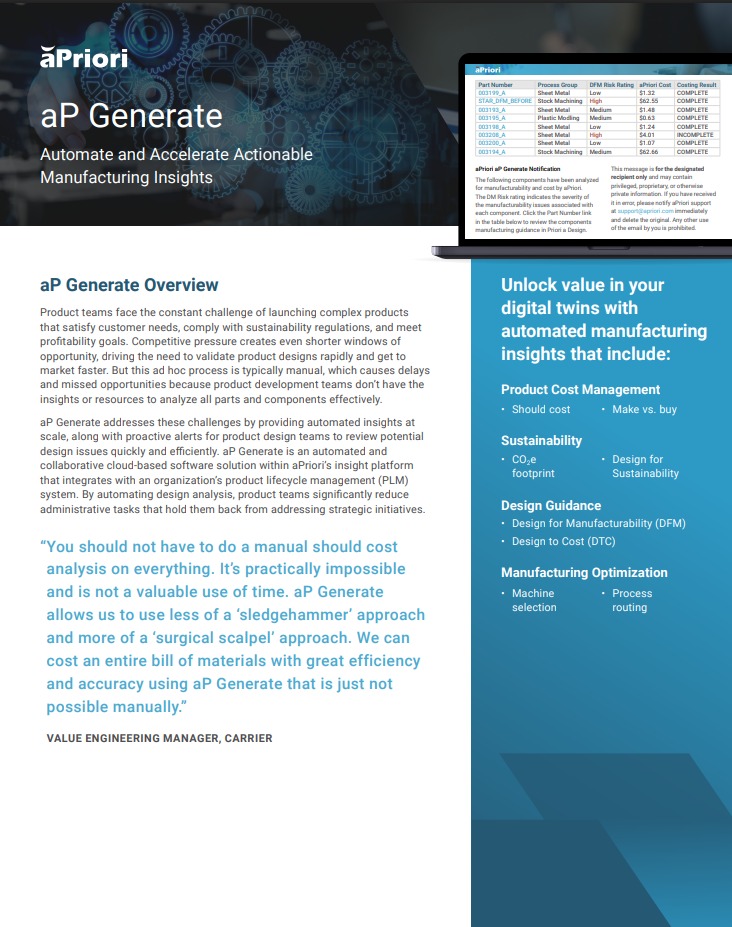

What a flatlining PLM system needs is a pulse generator—an external stimulus that can transform it from a passive archive into an active decision-making engine. It requires a continuous infusion of data that reflects the immediate consequences of every design choice. This is where aPriori’s manufacturability simulation engine comes in. It acts as the crucial data feeder, injecting a continuous, real-time stream of manufacturability, cost, and sustainability insights directly into the PLM environment at the earliest stages of the design process.

The process is straightforward but transformative. aPriori takes fundamental inputs that already exist within the PLM—CAD designs, material specifications, production volumes, and manufacturing locations—and runs them through its powerful analysis engine. In real-time, it simulates the entire manufacturing process, from tooling and material costs to labor and overhead. This generates a rich stream of actionable outputs that flow back into the PLM system, enriching the product data model. This isn’t just raw data; it’s predictive cost estimates, concrete Design for Manufacturability (DFM) feedback, and critical sustainability metrics like carbon footprint calculations. This constant pulse of information empowers the PLM system, transforming it from a passive data repository into an active, intelligent guide for every engineer.

The Recovery: Achieving Data-Driven Outcomes

With this newfound, continuous pulse of data, the entire product development lifecycle is reinvigorated. The PLM system becomes the dynamic, intelligent hub it was always meant to be, and the outcomes are tangible and transformative:

- Optimized Product Cost: Cost is no longer a historical data point but a live variable. With a clear, detailed breakdown of cost drivers available instantly for any design iteration, teams can make informed trade-off decisions. They can compare the cost implications of using a different material, switching from casting to machining, or altering a tolerance — all before a design is ever finalized. This shifts cost management from a reactive, post-design activity to a proactive, integrated part of the creative process.

- Accelerated Time to Market: By designing for manufacturability from day one, companies eliminate the costly rework and engineering change orders that plague traditional workflows. The endless loops between design and manufacturing are eliminated because manufacturing feedback is embedded directly in the design environment. This fosters true concurrent engineering, where sourcing and production teams can trust the data in the PLM and begin their work far earlier in the cycle, collapsing the overall product timeline.

- Greener, More Sustainable Products: Sustainability ceases to be an abstract goal or an end-of-life report. By generating a real-time carbon footprint assessment alongside cost and manufacturability data, organizations empower their engineers to treat sustainability as a core design metric. They can instantly see how a material change impacts both the price and the planet, allowing them to innovate for efficiency and environmental responsibility simultaneously.

By integrating aPriori’s Manufacturing Insights, a PLM system transforms into a dynamic hub for intelligent, profitable, and sustainable product development. It breaks down the silos between departments by providing a universally trusted and consistently updated data source. Teams can make proactive decisions with confidence, profit margins improve, and engineers are finally freed from the drudgery of data reconciliation to do what they do best: innovate.

Don’t let your investment flatline. It’s time to give your PLM system the pulse of real-time data it needs to drive the future of your business.

Learn How to Revitalize Your PLM System Today

Automated DFM Helps Improve Engineering Productivity

More Resources:

Learn More About How Automated DFM Analysis Can Revitalize Your PLM: